What Is Meniscus Coating? A Complete Guide to Perfect Thin-Film Deposition

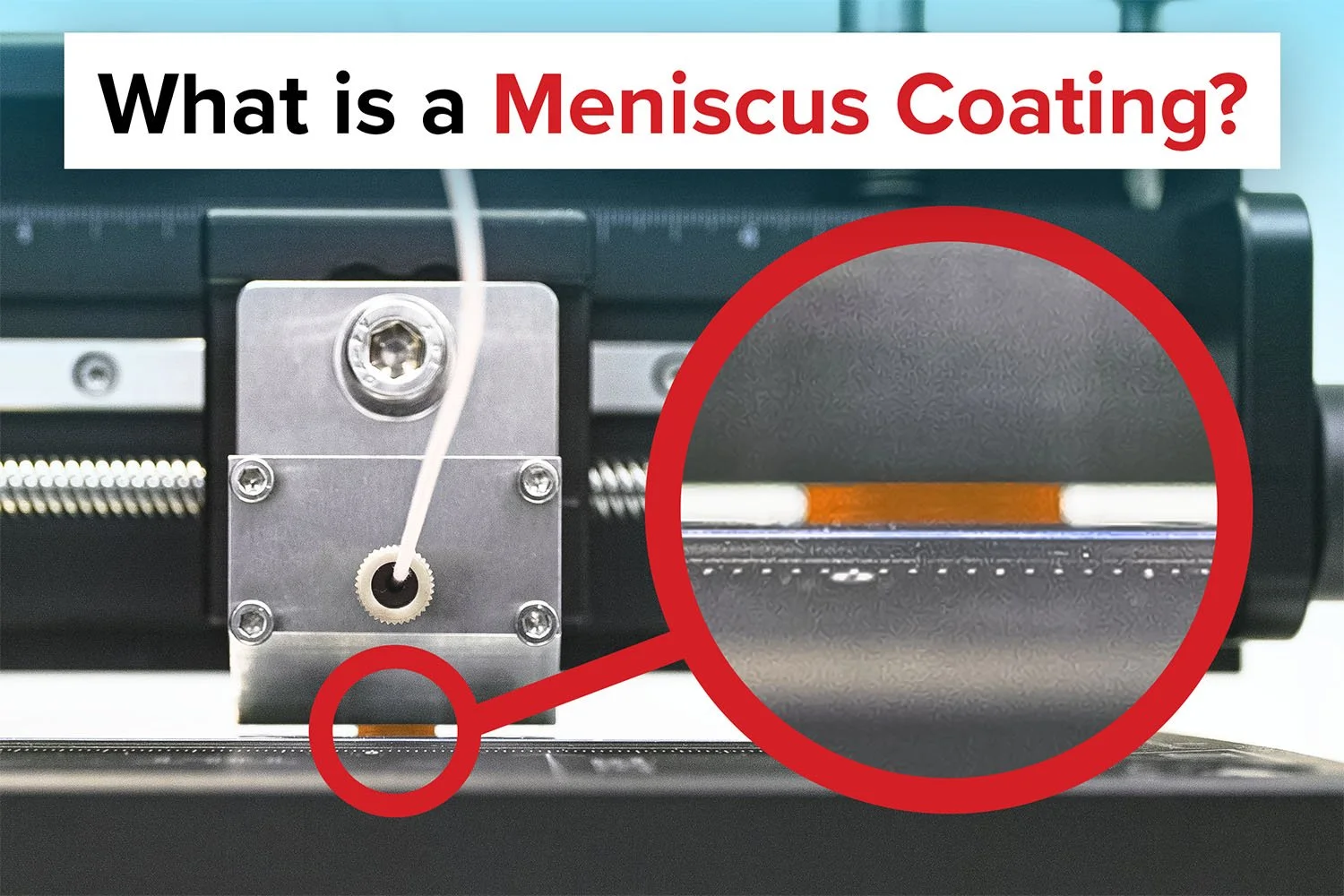

A meniscus is a “standing” liquid filling the gap between an “ink-supplier” (the thin film deposition unit) and a substrate. The shape and properties of the meniscus are very much dependent on the surface energies of the ink, the substrate and the “ink-supplier”, as well as the shape of the “ink-supplier”. Surface tension thus plays a huge role in meniscus coating.

Meniscus coating is the action of “dragging” the meniscus along the substrate while continuously feeding the meniscus with additional ink. The thickness of the resulting coated layer depends on several factors such as:

How fast is the meniscus dragged

How fast is the ink supplied

How wide is the coated layer

In cases of highly matching surface energies between the substrate and the ink, the shape of the meniscus will be low in height and wide in spread, often requiring a very narrow gap between “ink-supplier” and the substrate, whereas poorly matched surface energies result in high and narrow menisci.

When coating, if the surface energies of substrate and ink are too similar, the ink will start spreading on the substrate and it can essentially be difficult to make a defined coating as the ink will start flowing to the sides after the initial coat. On the other hand, if the mismatch in surface energy is too large the ink simply will not wet/coat the surface or will start to contract after the initial coat, an effect also called de-wetting.

Brush coating

A simple example of meniscus coating that most people can relate to is coating using a brush filled with paint. Here the hairs of the brush acts both as the ink-supplier and the reservoir and as the brush is dragged the meniscus between the brush and the substrate is continuously filled with paint from the supply inside the brush. If the brush is completely filled with paint, it is easy to make a brush stroke with an even coat (fast ink supply from a large reservoir) but when the brush has been used for some time only slow brush strokes will result in an even coat (slower ink supply from a lesser reservoir). If we try to move fast in the latter case, an uneven coating is obtained – a result of a depleted meniscus because of too slow ink supply.

In the case of using a handheld brush it can thus be challenging to create even coatings with the same thickness everywhere.

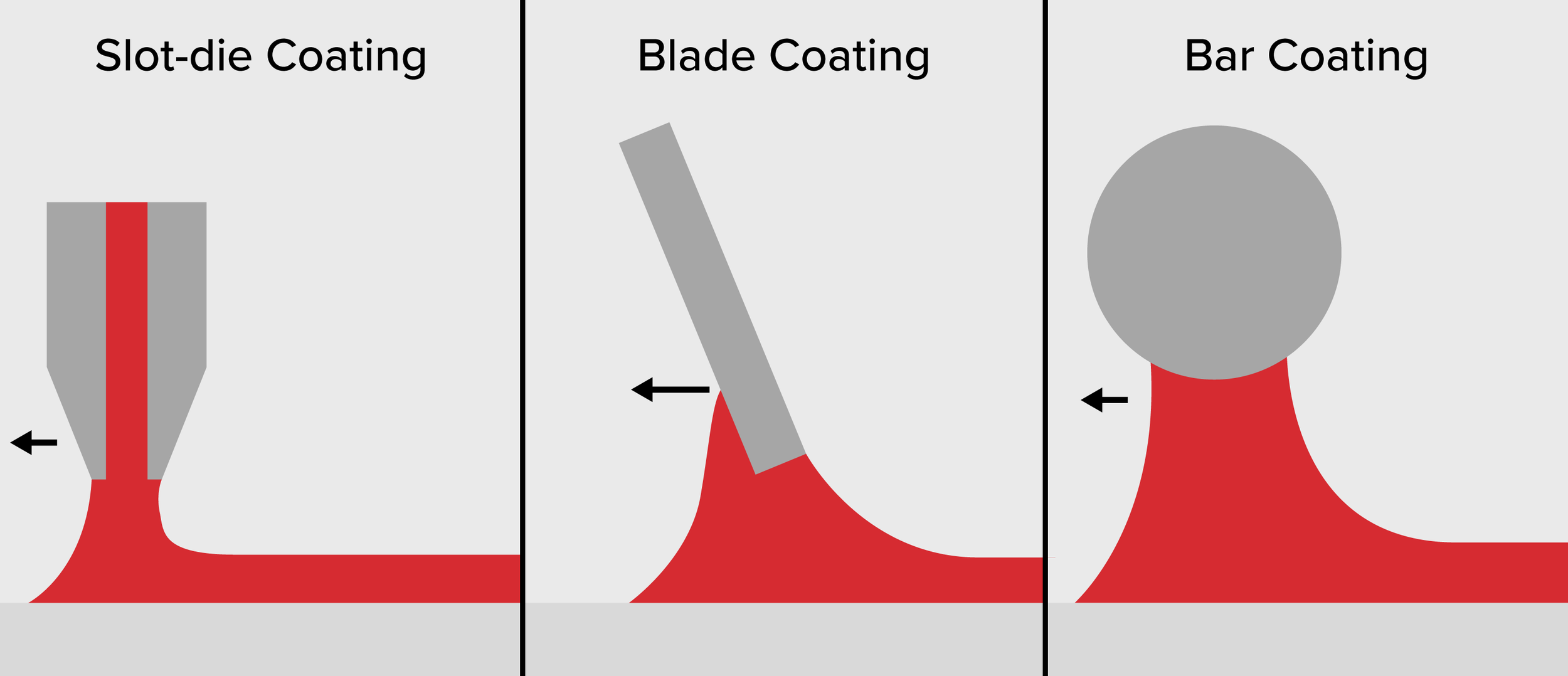

Slot-die coating

Slot-die coating is the most controlled form of meniscus coating as there is complete control of the layer thickness. Here the width of the coat is defined by the width of the slot in the slot-die head, and the thickness of the coat is defined by the combined effects of pumping speed and web speed.

Meniscus guide: In slot-die coating a meniscus guide can sometimes be used with advantage. The meniscus guide is an extrusion from the lip of the slot-die head that matches the width of the slot in the slot-die head and as the name implies it guides the ink down towards the surface. The use of a meniscus guide is especially useful for low viscus inks in aiding that the ink doesn’t start spreading outside the extremities of the slot. As low viscus inks can easily flow sideways along the lip of the slot-die head when thicker wet layers are coated, they require very fine tuning of the coating height if meniscus guides are not used. Using a guide forces the ink (gravity) to flow towards the lower part of the guide, extending the distance to the parts of the lip where coating is not desired.

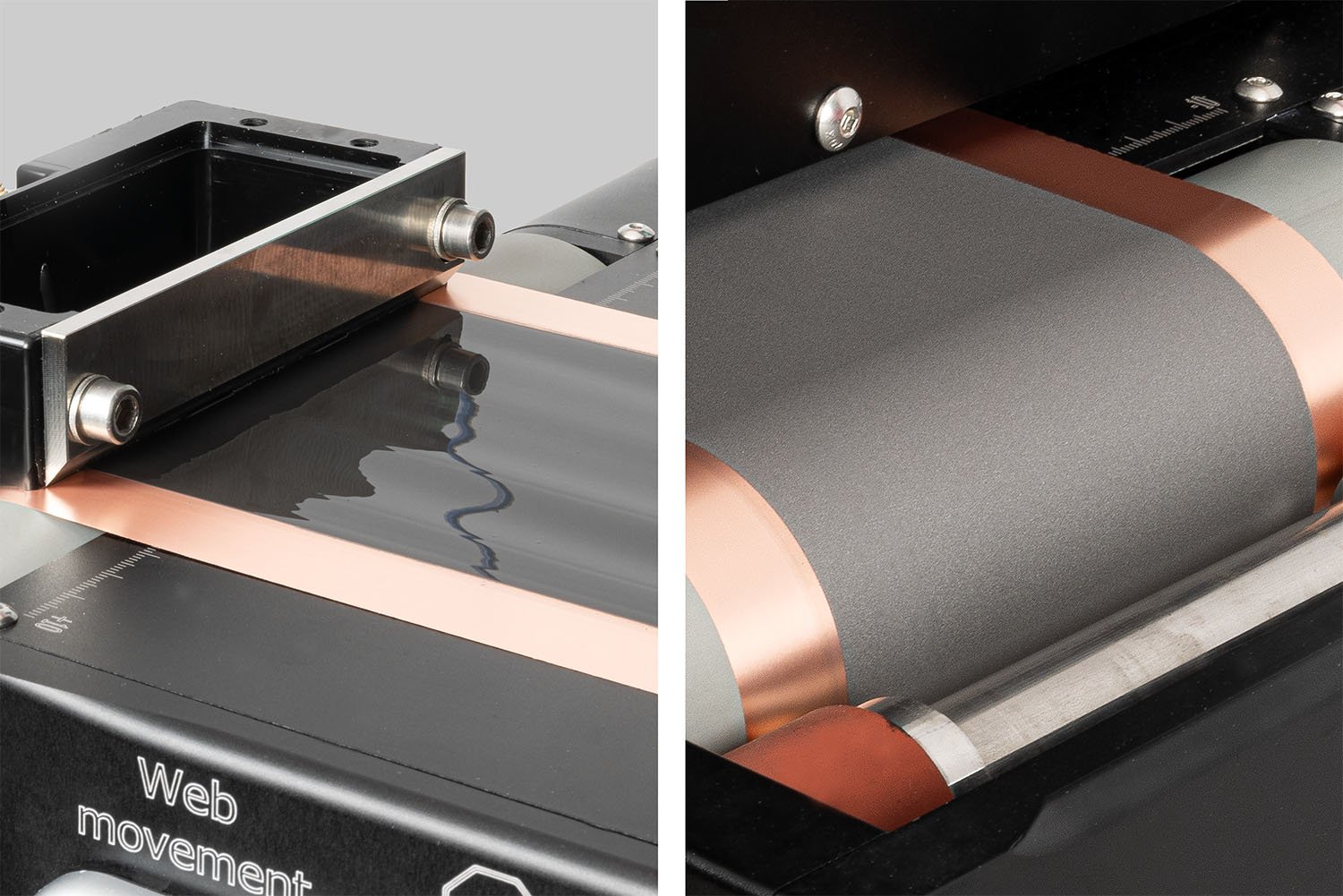

Patterned slot-die shim and meniscus guide: Slot-die coating furthermore allows for patterned coatings in the form of stripes. The lot of the slot-die head is here divided into several slots using a shim, blocking parts of the full slot. Using a meniscus guide that fits the width of the slots in the shim typically helps separate the various stripes, especially if they are close together.

Slot-die coating stripes.

Knife Coating

Knife (Blade) Coating

In knife coating (also sometimes called blade coating) an excess of ink is pushed in front of a moving knife placed at a specific distance over a substrate. The gap between the knife and the substrate allow for ink to pass under the knife crating the coat. As one side of the knife always have excess ink there is no “free-standing” meniscus when compared to slot-die coating, but the dynamics on the “exit” side are similar.

In knife coating the thickness of the coat cannot be defines as easily as for slot-die coating but is a function of the gap between the substrate and the knife and the ink/substrate surface energies.

Bar Coating

In a similar way to knife coating, bar coating is carried out by pushing an excess amount of in front of a bar. Depending on the kind of bar used the method is also referred to as rod coating, Mayer bar coating or wire bare coating. Typically, grooves in the bar, or wires wound around it, allows for ink to pass underneath the bar as it this moves forward, and a meniscus form on the backside of the rod as a result of surface tension. This meniscus is the reason why a uniform coat can be obtained although the ink in reality is supplied trough a multitude of small channels (the grooves) in the rod.

Conclusion

In conclusion, meniscus coating is a precise process driven by the interplay of surface tension, surface energies, and the mechanics of ink delivery. Achieving a perfect coating requires careful control of parameters such as ink supply rate, substrate movement, and surface compatibility. Different techniques like brush, slot-die, knife, and bar coating offer varying levels of control, with slot-die being the most regulated. Proper management of the meniscus through tools like meniscus guides and patterned shims enables the production of uniform and patterned coatings, essential for high-quality applications. Mastery of meniscus behaviour and coating techniques is key to optimizing film thickness, uniformity, and functionality in various industrial processes.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.