What is LBIC? A Complete Guide to Solar Cell Characterization

What is LBIC and How to Characterize Solar Cells Using LBIC

LBIC (Light Beam Induced Current) is a powerful diagnostic technique used to analyse and characterize photovoltaic devices, particularly solar cells. In this method, a focused light beam (usually from a laser) is scanned across the surface of a solar cell to measure the induced current at various points. The LBIC technique provides spatial resolution, allowing researchers to map the response of the solar cell to light exposure, revealing information about its performance, defects, and inhomogeneities.

How LBIC Works

A laser (often modulated) is used to illuminate the surface of a solar cell. The setup typically includes a laser source, a lens for focusing the beam, a sample holder to position the solar cell, and a measuring device (such as a picoammeter) to detect the photo-response.

The focused light beam is scanned across the solar cell's surface in a systematic manner. As the laser beam hits different areas of the solar cell, it generates electron-hole pairs, leading to a photo-response that can be associated with this specific point/area of the solar cell. Scanning the complete surface of the solar cell gives a pixelated 3D image (x,y coordinates + intensity) of how well the solar cell is performing, showing potential defects and/or poor performing areas.

Historically, the scan has usually been performed point by point or in a raster pattern, but solutions/setups that allows for fast scanning using continuously moving laser beams are now available. This has reduced the scan time from days/hours to minutes/seconds bringing LBIC to forefront of the available tools for analysis and defect finding of solar cells.

LBIC in Academia

Within solar cell research focus is typically aimed at increasing performance of the solar cells and increasing the lifetime/stability of the solar cell. For both areas LBIC is a perfect analysis tool.

Device Performance – Finding the Right Size of the Active Area of a Solar cell

In solar cell research the prepared solar cells are often very small (a few mm2) and since you need the active area (the area of the solar cell that generates power) in order to determine how efficiently it converts slight into power. With small size comes the need for higher precision when determining the active area, as deviations can lead to high errors on the performance. As an example, let us try to look a deviation of 0.1 mm when of 2 square solar cells: Cell A: 100 mm x 100 mm, Cell B: 2 mm x 2 mm.

Cell A: a 0.1 mm deviation has very little impact on the determination of the area of a 100x100 mm2 cell:

99.9 mm x 99.9 mm = 9980.01 mm2

100.1 mm x 100.1 mm = 10020.01 mm2

9980.01 mm2 ≈ 10000 mm2 ≈ 10020.01 mm2

Deviation ≈ 0.2%

Cell B: a 0.1 mm deviation has a large impact on the determination of the area of a 2x2 mm2 cell:

1.9 mm x 1.9 mm = 3.61 mm2

2.1 mm x 2.1 mm = 4.41 mm2

3.61 mm2 < 4 mm2 < 4.41 mm2

Deviation ≈ 10%

As LBIC will give a photo-response only where the solar cell is producing power it is possible to very accurately determine the active area of a solar cell by scanning its surface. It also allows for easy determination of “non-rectangular” shapes.

Lifetime/Stability — Degradation Detection

When performing lifetime studies, one of the difficult things to determine is the cause of an observed degradation. Comparing IV-curves can easily tell us if the efficiency is going down, but whether this is because the whole solar cell is performing less or if it is only a small part of the solar cell that is performing less is not possible to tell by conventional IV data.

LBIC can do this easily and thus becomes a powerful tool in understanding the degradation mechanisms of solar cells.

LBIC in industry – defect finding

Going to manufacture of solar cells, defect finding through process monitoring becomes an important tool, as fast detection and subsequent resolving of manufacturing defect can save both time and money for the manufacturer. Again, LBIC is a powerful tool to find deviations in the expected photo-response from the produced solar cells.

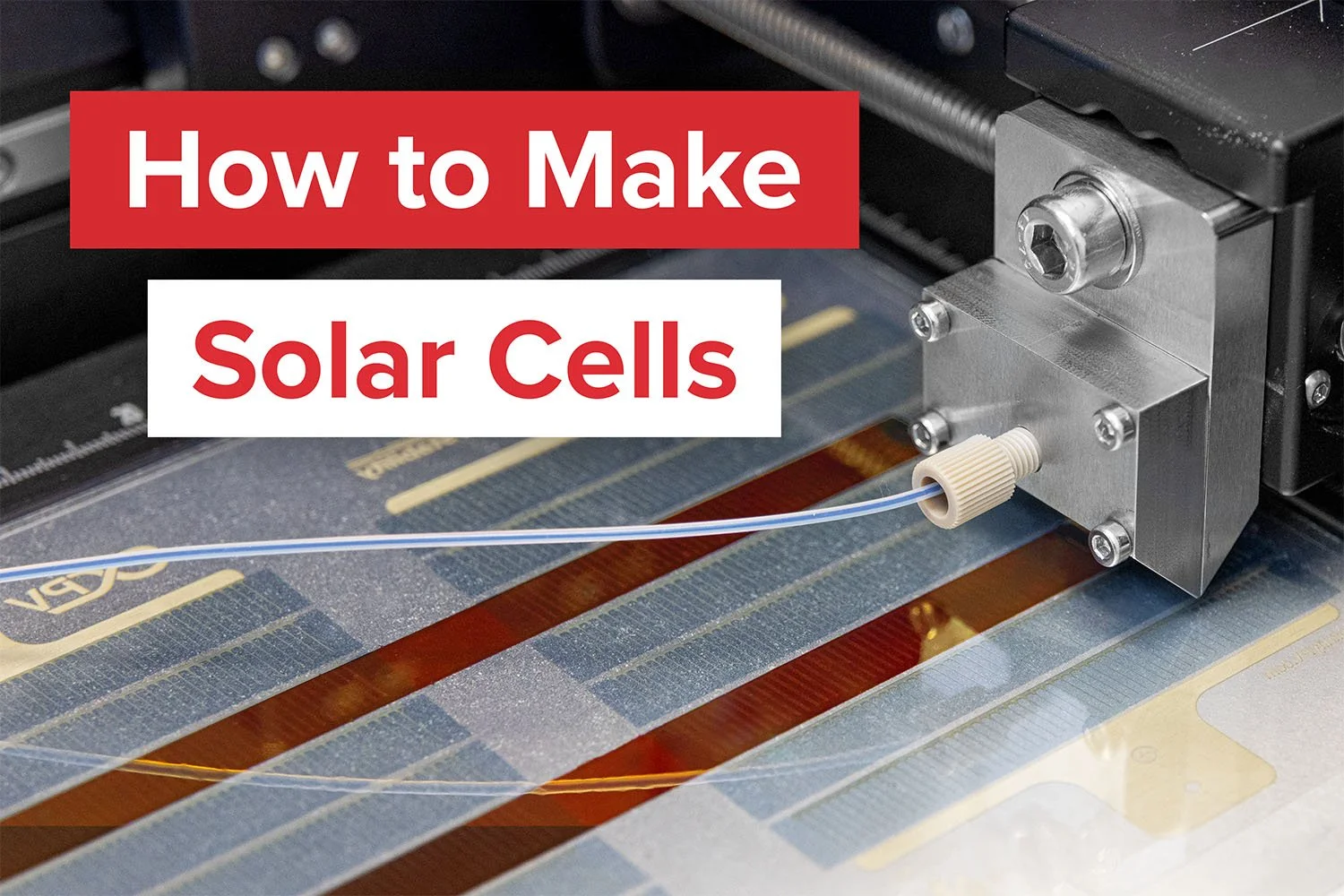

LBIC on an industrial scale can either be carried out simply by scaling the setup to be able to handle larger sizes or by using setups where the solar cells continuously pass by the LBIC. For rigid solar cells the latter can be carried out using a conveyer belt and for flexible solar cells the R2R processed solar cells can simple be analysed inline as part of the manufacturing process allowing for immediate reaction to production deviations or errors.

Example of a R2R LBIC.

Get Professional Support for Your Coating Needs

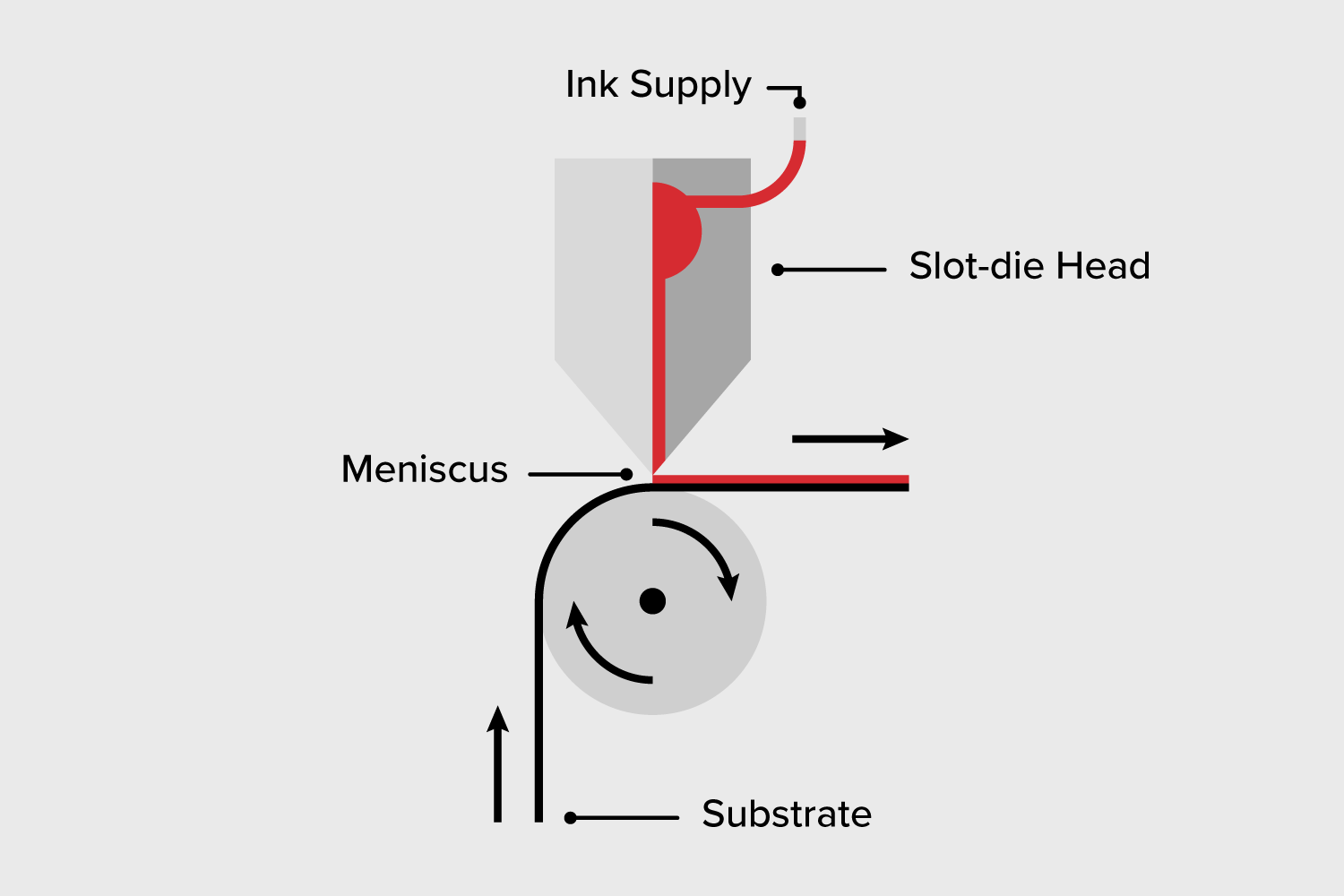

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Articles

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater. A compact, fully integrated R2R coater that fits on a workbench, in a fume hood or a glovebox.

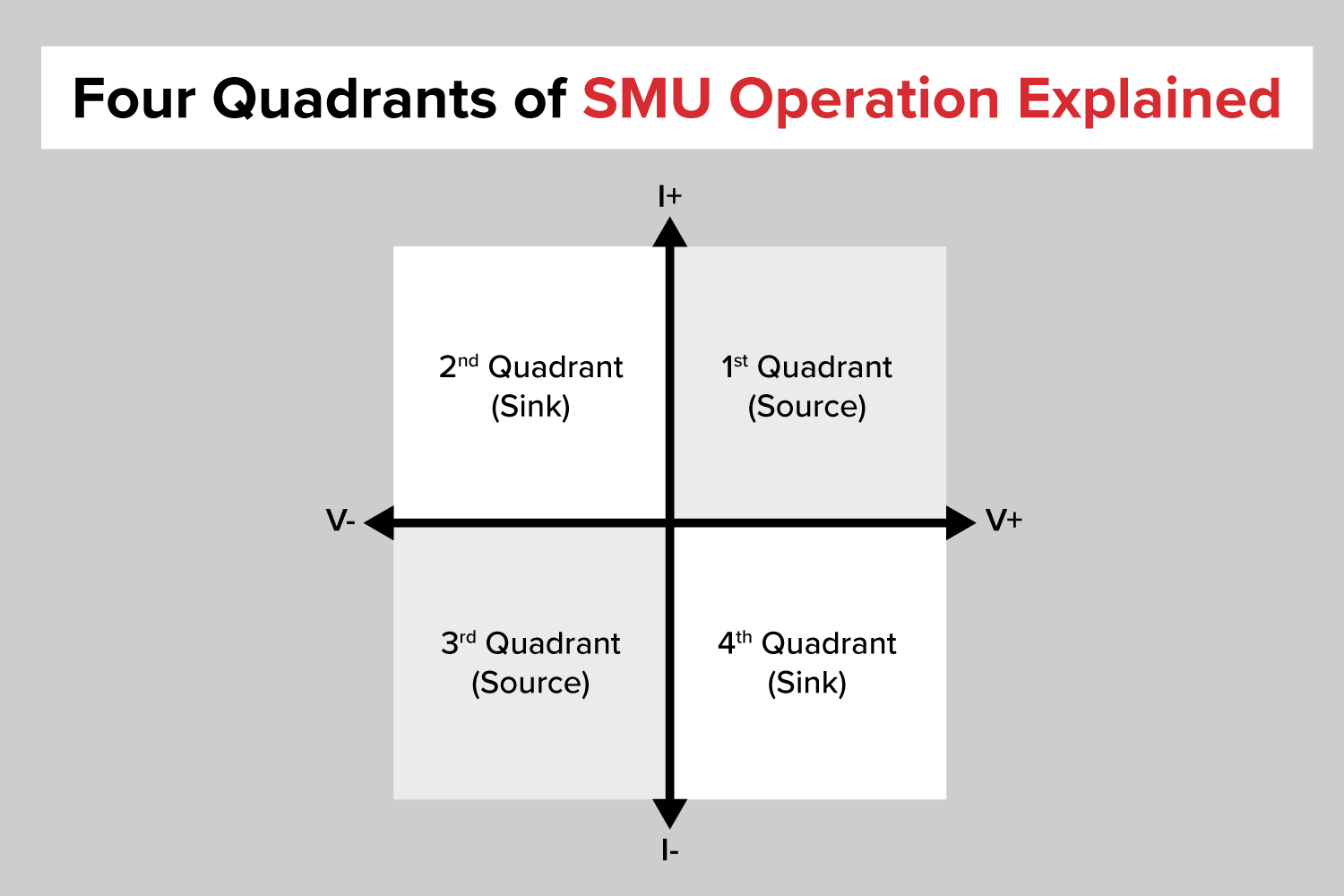

The Low Power 8 Channel Source Measure Unit with MPPT is specifically tailored for laboratory PV devices and compact modules, supporting voltages of up to 5 V and currents of up to 40 mA, with a maximum of 200 mW per channel.