infinityPV Launches Custom Foil Converting Solutions

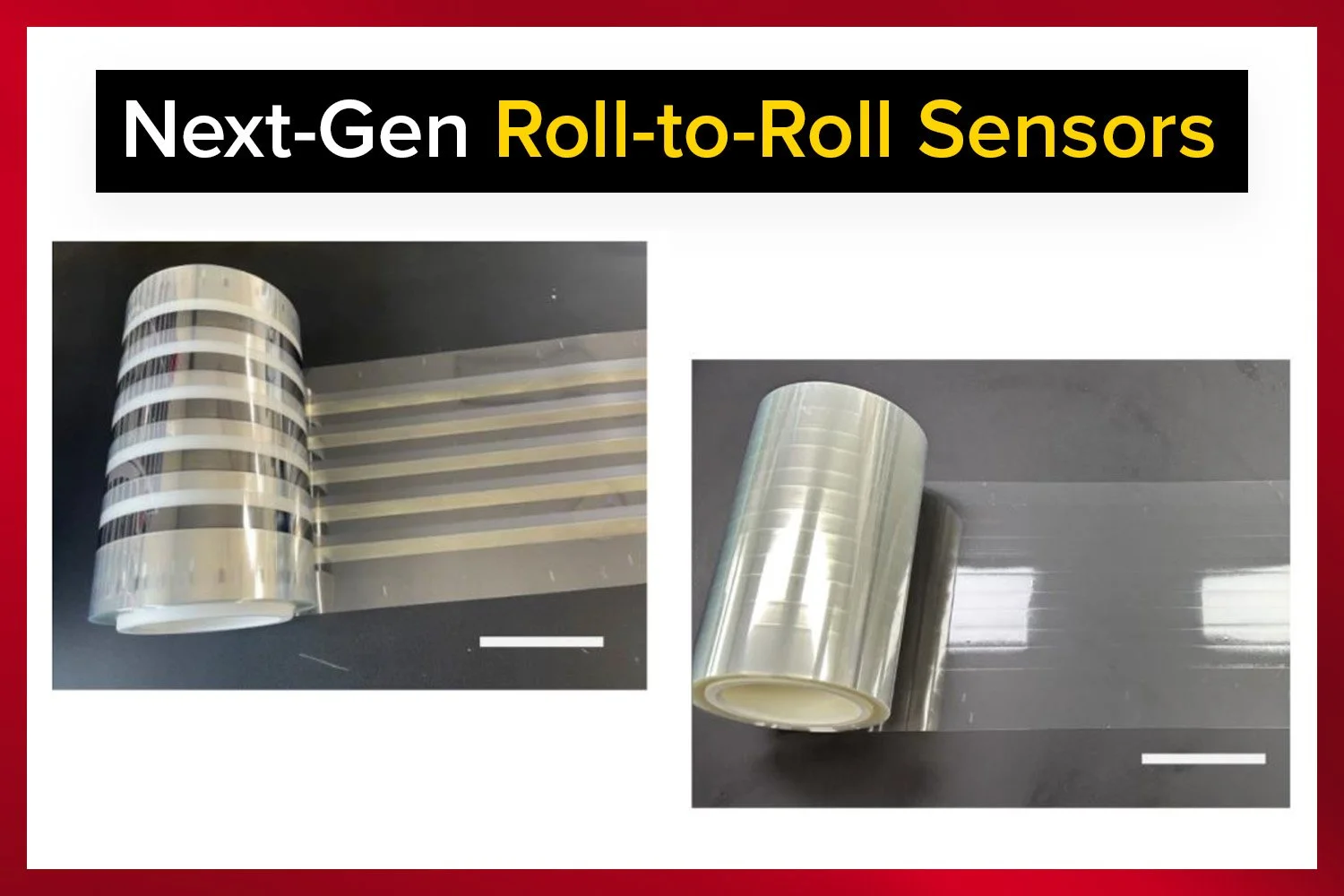

infinityPV is proud to announce the launch of its Custom Foil Converting Solutions, designed to transform raw foil and substrate materials into precisely tailored products for seamless integration into your manufacturing line, including infinityPV processing platforms.

Raw materials rarely meet the exact requirements of specialized applications. With this new service, infinityPV can modify the dimensions, structure, and properties of foil rolls, ensuring they perfectly align with your specific process or application.

Our foil converting services serve a wide range of industries, including electronics, packaging, medical devices, and renewable energy. By providing expertly converted materials, we help clients enhance product quality, streamline manufacturing processes, and reduce overall production costs. We work with a variety of foil types, including aluminium, copper, plastic, paper, membranes, and bio-based materials, supporting applications such as battery manufacturing, solar cells, fuel cells, MedTech and Pharma, packaging, adhesives, and hydrogen technology.

The services offered include precise slitting to convert wide rolls into the exact widths required, as well as rewinding to optimize roll quality with controlled tension, edge guiding, and defect removal. Even tension distribution during rewinding ensures uniform roll density, smooth unwind, and minimal wrinkles or creases, which is crucial for roll-to-roll processing. Edge guiding guarantees perfectly aligned roll edges, while core size conversion adapts rolls to the specifications of your equipment. InfinityPV also provides precise foil length rolls, splitting master rolls into defined lengths to match your process, and trimming to remove edge imperfections, correct misalignments, and achieve exact widths for a professional finish.

Contact infinityPV today to learn more about how our Custom Foil Converting Solutions can support your manufacturing needs and transform your raw foil into precision-engineered rolls perfectly matched to your process.

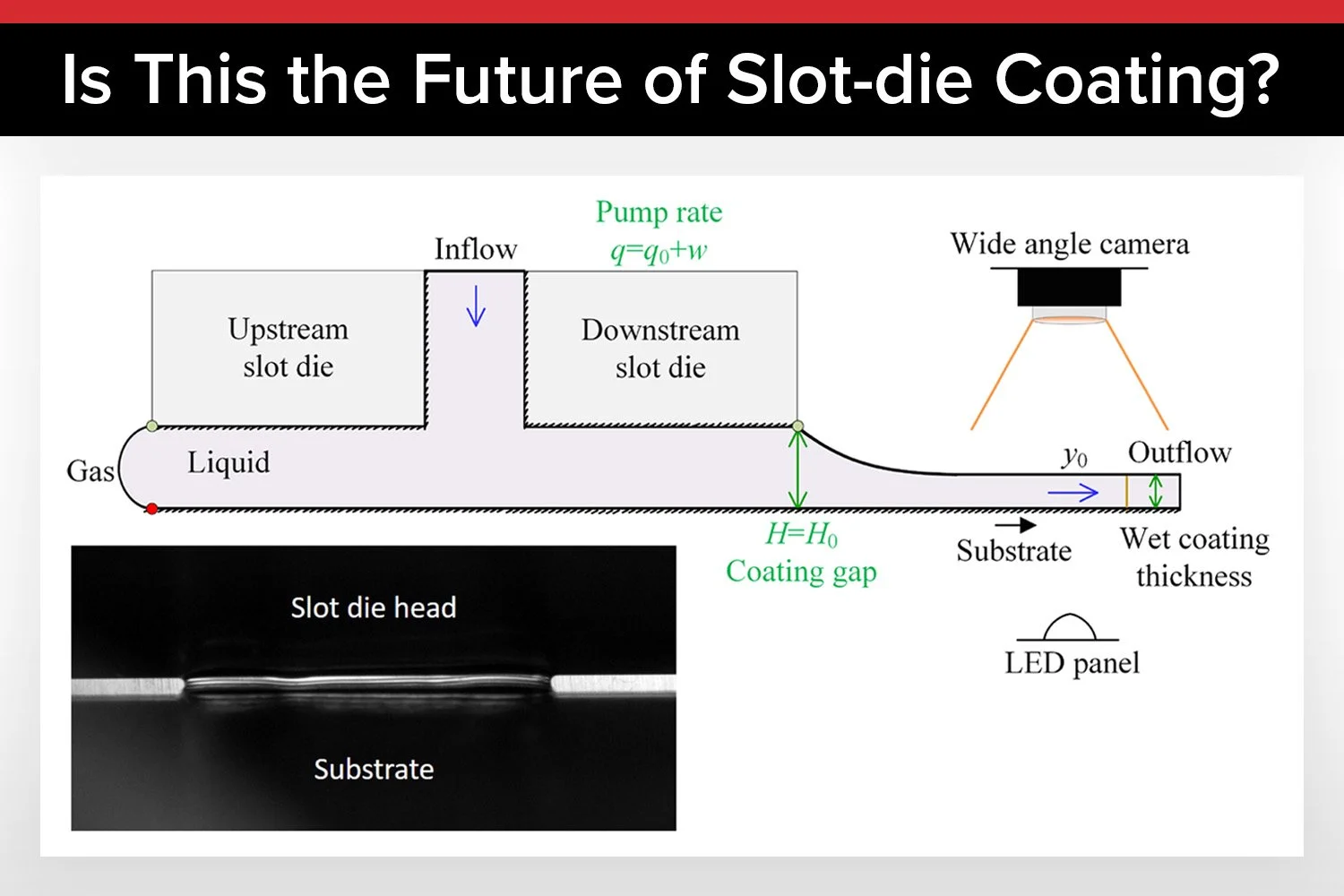

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.