Can We Finally Achieve Flawless Slot-die Coating? A New AI Breakthrough Says Yes

Imagine a world where every lithium-ion battery, solar cell, or flexible electronic device is coated with absolute precision. No defects, no wasted material, no inconsistencies. It sounds like an engineer’s dream, but a recent study titled Disturbance observer-based tracking control for roll-to-roll slot die coating systems under gap and pump rate disturbances brings us closer to making it a reality.

Roll-to-roll slot die coating is a high-speed manufacturing process used to produce everything from battery electrodes to optical films. The challenge, however, lies in maintaining perfect uniformity. Even the smallest disturbances, like vibrations from machinery or fluctuations in fluid flow, can disrupt the coating process, leading to defects and inefficiencies.

Now, researchers from University College London and the University of Sheffield have developed an AI-driven control system that actively detects and corrects these disturbances in real time. Using a slot-die head from infinityPV, the team demonstrated how their method ensures that coating thickness remains consistent, even when faced with unexpected disruptions.

Key Highlights:

A disturbance observer-based optimal tracking control (DOBOTC) system was developed to correct disturbances in real time, ensuring consistent coating thickness in roll-to-roll manufacturing.

The system uses a slot-die head from infinityPV to demonstrate precision even under challenging conditions, such as fluctuations in coating gap and pump rate.

An AI-driven optimal tracking controller continuously adjusts the process, keeping the coating within desired specifications and minimizing waste and defects.

The Problem with R2R Slot-die Coating

Roll-to-roll slot die coating is widely used in industries like batteries, solar cells, and flexible electronics because of its speed and efficiency. The process involves extruding a liquid material through a narrow gap onto a moving substrate, creating a thin, uniform film. But in reality, maintaining that uniformity is far from simple.

In a real-world manufacturing environment, the process is constantly subjected to small-scale disturbances. Mechanical vibrations from rollers, fluctuations in pump pressure, and variations in substrate speed can all introduce inconsistencies. These disturbances might seem minor, but they can have a significant impact on the final product:

For example, in lithium-ion batteries, even slight variations in coating thickness can affect energy density and power output.

In solar cells, uneven layers reduce efficiency.

And in flexible electronics, defects can lead to performance issues or complete failure.

Traditional control methods struggle to compensate for these disturbances in real time. Most systems rely on pre-set programs that don’t adapt to changing conditions, leading to higher rejection rates, material waste, and lower production yields. The need for a smarter, more responsive solution has never been greater.

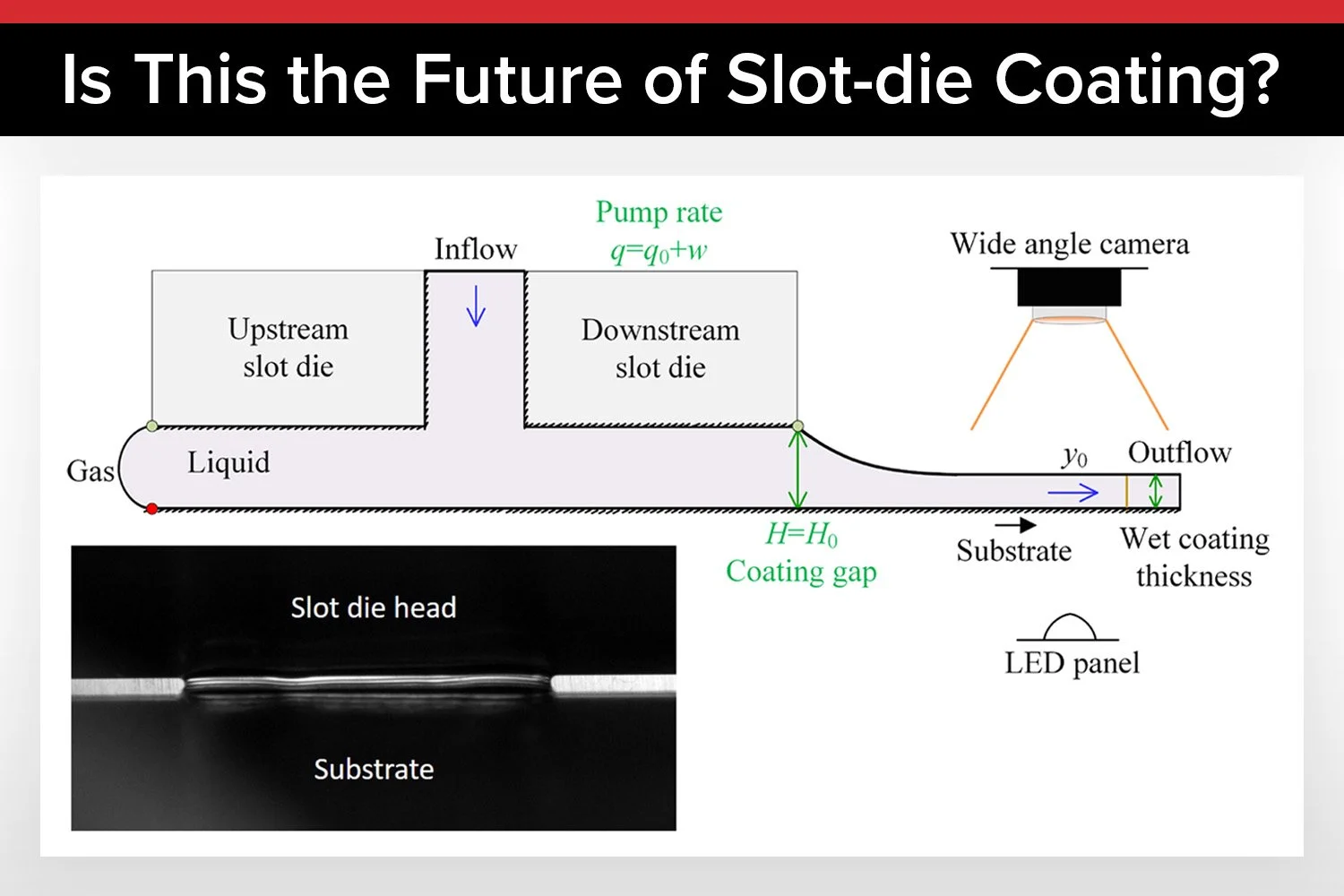

Example of how a roll-to-roll coater works.

The Solution: AI That Detects and Corrects Disturbances in Real Time

The researchers behind this study have developed a groundbreaking approach that combines two powerful techniques: disturbance observers (DO) and optimal tracking control. Here’s how it works.

First, the system uses a disturbance observer to monitor the coating process in real time. The observer detects any deviations from the ideal state, whether they’re caused by mechanical vibrations, pump fluctuations, or other disruptions. It then estimates the magnitude and nature of these disturbances, providing critical data for the next step.

Next, the optimal tracking control system takes over. This AI-driven controller continuously adjusts the coating process to keep the film thickness within the desired range. It does this by balancing control effort with performance, ensuring that corrections are made efficiently and effectively. The result is a closed-loop system that not only reacts to disturbances but actively neutralizes them before they can affect the final product.

What makes this approach particularly innovative is its use of data-driven modeling. The researchers built their system using real experimental data, allowing it to adapt to real-world conditions. This ensures that the control system isn’t just theoretically sound but practically effective in an industrial setting.

Why This Breakthrough Matters for Industry

The implications of this research extend far beyond the lab. For industries that rely on precision coating, the ability to maintain consistent thickness could lead to significant improvements in quality, efficiency, and cost.

In the battery industry, for example, uniform coating is essential for maximizing energy density and power output. With this new control system, manufacturers could produce batteries with fewer defects, higher performance, and lower material waste.

Similarly, in solar panel production, consistent coating thickness improves light absorption and overall efficiency.

For flexible electronics, precise layers ensure optimal electrical properties, enabling more advanced and reliable devices.

But the benefits don’t stop there. By reducing defects and waste, this technology could also lower production costs and increase yields. Factories could run faster and more efficiently, with fewer interruptions for quality checks. And because the system is adaptive, it could be scaled up for use in full-size industrial machines, making it a practical solution for real-world manufacturing challenges.

How the Researchers Made It Happen

To develop and test their control system, the researchers built a custom roll-to-roll slot die coater in the lab. The setup included:

A syringe pump to control fluid flow

A slot-die head from infinityPV to demonstrate precision even under challenging conditions, such as fluctuations in coating gap and pump rate.

A wide-angle camera to monitor coating thickness in real time

Stepper motors to adjust the coating gap and substrate speed.

They used a titanium dioxide nanoparticle solution — a material commonly found in industrial coatings — to simulate real-world conditions.

The team then introduced controlled disturbances, such as periodic oscillations in the coating gap and fluctuations in pump rate, to mimic the challenges faced in actual manufacturing environments. The camera captured high-resolution images of the coating process, which were analyzed to detect thickness variations and other defects.

With this data, the researchers developed their AI control system.

The disturbance observer detected and estimated the disturbances, while the optimal tracking controller adjusted the process to maintain uniformity.

The results were impressive: the system successfully corrected for both matched and mismatched disturbances, proving its effectiveness in a variety of scenarios.

The system uses a slot-die head from infinityPV to demonstrate precision even under challenging conditions, such as fluctuations in coating gap and pump rate.

The Future of Smart Manufacturing

This study represents a glimpse into the future of manufacturing. As industries push for higher precision, faster speeds, and lower costs, technologies like this one will become increasingly essential. The ability to actively detect and correct disturbances in real time could lead to fully autonomous, self-correcting production lines where machines fix their own mistakes without human intervention.

Looking ahead, the researchers plan to scale up their system for use in industrial machines. They’re also exploring ways to integrate machine learning, which could allow the system to predict and prevent disturbances before they even occur. And while this study focused on slot die coating, the principles could be applied to other coating methods, such as curtain coating or gravure coating, further expanding its potential impact.

For companies that specialize in coating equipment, this technology could soon become a standard feature, offering smarter, more reliable systems to manufacturers around the world.

Conclusion: A Smarter, More Efficient Way to Coat

The study Disturbance observer-based tracking control for roll-to-roll slot die coating systems under gap and pump rate disturbances presents a significant leap forward in precision manufacturing. By combining disturbance observation, optimal control, and data-driven modeling, the researchers have created a system that actively corrects errors in real time, ensuring perfectly uniform coatings even in the face of disruptions.

Authors

Zezhi Tang

Christopher Passmore

Andrew I. Campbell

Jonathan Howse

J. Anthony Rossiter

Stephen Ebbens

George Panoutsos

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.