Breakthrough in Medical Films: Smart Coating Changes Color

Can a Wound Dressing Be Smarter Than a Doctor?

A recent study titled “Smart Antibacterial Coatings with On-Demand Drug Release and Real-Time Monitoring” introduces a new kind of medical coating that not only protects against bacteria but also actively communicates when it has done its job. Through a simple visual change in color, this intelligent film can tell healthcare professionals and even patients themselves when drug levels are running low, when it is time to replace a dressing, and how the wound is progressing.

This breakthrough tackles two longstanding challenges in wound care and implantable medical devices. Infections caused by bacterial colonization remain a serious issue for implanted devices such as catheters, orthopedic nails, and surgical dressings. Additionally, current antimicrobial coatings either release too much antibiotic too quickly or provide no insight into how much active drug remains. The new coating system solves both problems using a smart, self-reporting material made from antibiotics and metal-organic structures. It is simple to produce, adaptable to many surfaces, and highly effective in both laboratory and animal models.

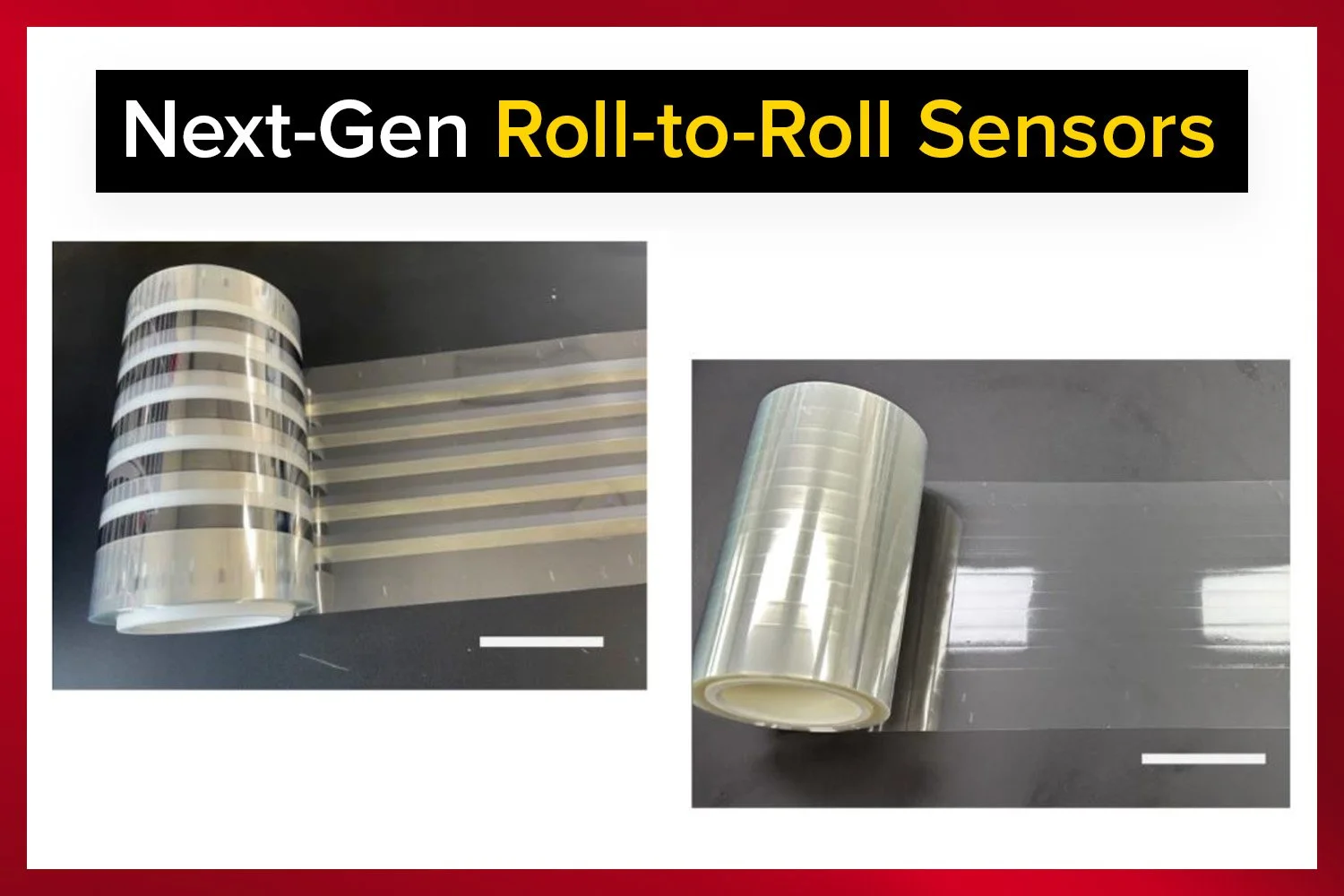

The relevance of this technology extends beyond medicine. Its compatibility with large-area substrates and its ability to be applied through wet-coating techniques make it a strong candidate for roll-to-roll manufacturing systems. In other words, this innovation is both manufacturable and intelligent.

Key Highlights

The coating changes color to indicate how much drug is left, allowing for easy visual monitoring.

Antibiotic release is triggered by the environment, especially acidic conditions typical of infections.

Proven effectiveness against both Gram-positive and Gram-negative bacteria.

Can be applied to many materials, regardless of surface chemistry.

Enables real-time tracking using smartphone cameras and simple software.

Does not require complex equipment or processes for fabrication.

Demonstrated successful infection prevention in live animal models.

Compatible with various antibiotics and metal ions for flexible customization.

Understanding the Coating: What It Is and Why It Matters

The coating developed in this study combines aminoglycoside antibiotics, such as tobramycin and gentamicin, with metallosupramolecules. These are structures formed from metal ions and multifunctional ligands. These components come together through a simple, solution-based reaction that forms a thin, durable film when deposited onto a surface.

What makes this system particularly innovative is that it does not rely on surface-specific chemistries. It can be applied to plastics, metals, textiles, and even irregular geometries without altering the underlying material. Once applied, the coating forms a network capable of holding and releasing antibiotics in response to environmental triggers.

The standout feature is its built-in feedback mechanism. Iron ions within the film create a visible color. As antibiotics are released, those iron-ligand structures break down and the color fades. This visual cue can be easily tracked without expensive tools, providing direct insight into how the coating is performing.

A New Paradigm in Wound Care and Device Safety

Bacterial infections in implanted medical devices continue to be a major challenge in healthcare. Over 100,000 deaths per year in the United States are linked to these infections. Existing coatings often deliver antibiotics in an uncontrolled manner or are difficult and costly to produce.

The new coating offers a clear improvement. It delivers protection, releases drugs when triggered by infection-related changes, and provides a visual indicator of drug levels. Since it is applied using liquid-phase chemistry, it is also suitable for large-scale production, including roll-to-roll systems where materials are coated and processed continuously.

With this system, clinicians gain an objective tool for monitoring wound treatment. They no longer have to rely solely on visual assessment or trial-and-error decisions about dressing changes. This leads to more accurate, timely interventions and potentially faster recovery times.

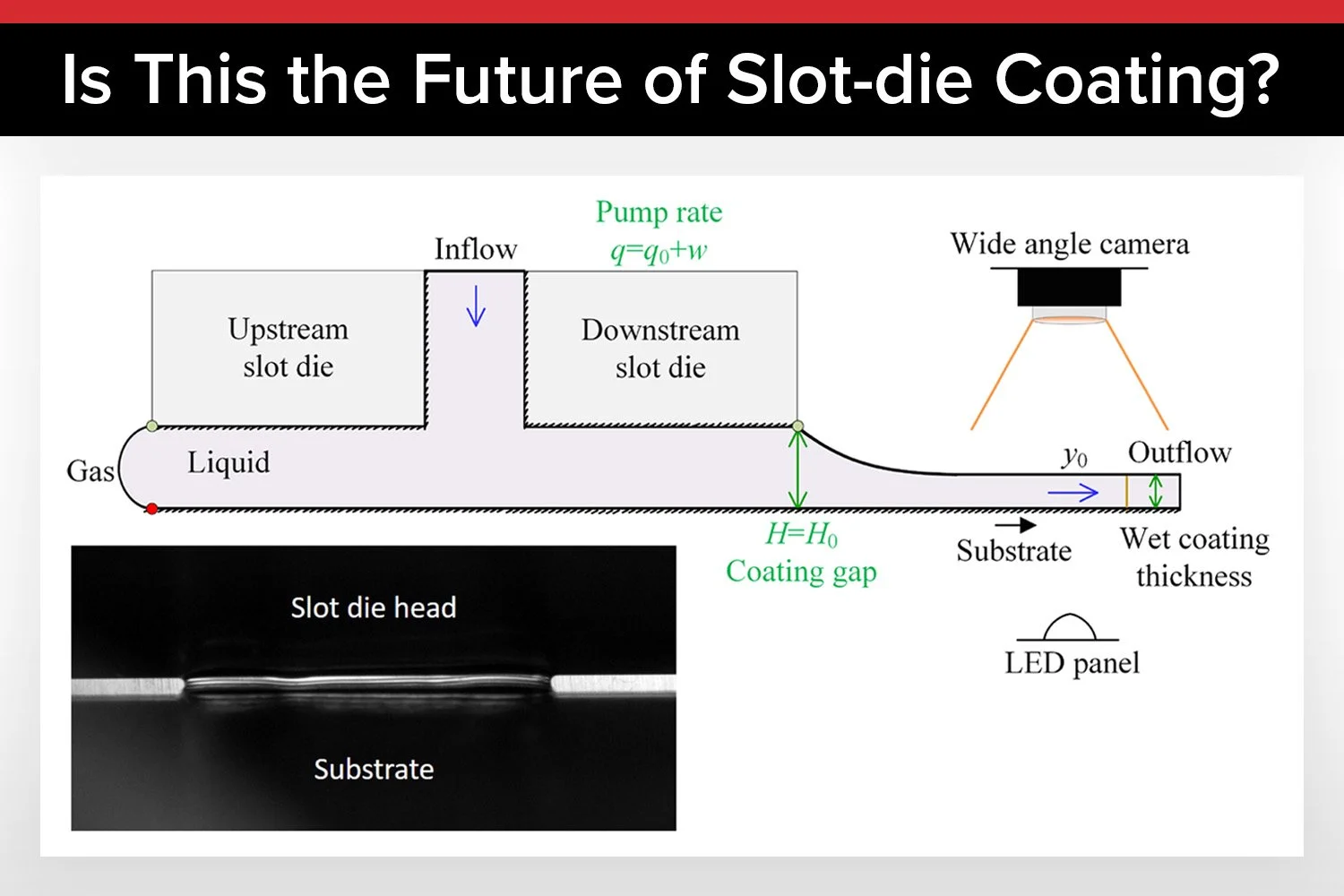

Learn the complete process of creating uniform thin films using a slot-die coater.

Fabrication: Simple and Scalable

To create the coating, researchers combined tobramycin, 2-pyridinecarboxaldehyde, and ferrous sulfate in water. The mixture was applied to a clean surface such as cellulose acetate or glass. As it dried, metal-ligand coordination bonds formed a stable coating that encapsulated the antibiotic.

Unlike vapor-deposition or layer-by-layer systems, this approach uses only aqueous solutions at room temperature and requires no pretreatment of the surface. This simplicity allows it to be easily integrated into industrial coating methods such as slot-die coating, blade coating, or spray application.

The final coating was tested using atomic force microscopy and scanning electron microscopy, showing a uniform surface with consistent thickness. Chemical analysis confirmed that the antibiotic and metal components were successfully incorporated into the film, resulting in a chemically robust and highly functional coating.

Color as a Signal: Monitoring in Real Time

As the coating releases antibiotics, its color begins to change. The breakdown of metal-ligand complexes reduces the intensity of the film’s coloration, which can be measured using basic imaging tools. The team demonstrated that RGB values extracted from smartphone photos correlate strongly with remaining drug levels.

To make the monitoring process user-friendly, the researchers developed a simple software tool that uses images to calculate drug content based on color changes. The results can be displayed on a computer or mobile phone, allowing for real-time decision-making without needing laboratory instruments.

This type of visual monitoring makes the coating particularly valuable in clinical settings where equipment access is limited or rapid feedback is essential.

Laboratory Results Confirm Antibacterial Effectiveness

The researchers tested the coating against two common bacterial strains, Escherichia coli and Staphylococcus aureus. Results showed large zones of inhibition, meaning that bacterial growth was strongly suppressed in the areas surrounding the coated surfaces.

Microscopic examination revealed that bacteria on the coated surfaces had ruptured membranes, while bacteria on uncoated materials remained intact. The coated surfaces killed more than 90 percent of the bacteria, demonstrating the coating’s strong performance as an antibacterial material.

The Laboratory Roll-to-Roll Coater makes double-sided slot-die coating simple.

Expanding the Platform: Adapting to Other Drugs and Metals

The researchers extended the coating method to include several other aminoglycoside antibiotics such as gentamicin, neomycin, and streptomycin. They also tested coatings made with different metal ions including copper, zinc, and nickel. Each variation produced coatings with distinct colors and drug release profiles.

This flexibility means the platform can be customized for different clinical applications. The color can be tailored for visibility, the drug release rate can be adjusted, and the coating can be adapted for specific pathogens or patient needs.

Because the coating is prepared from simple chemical ingredients and does not depend on specialized surfaces, it is ideal for large-scale production and commercial use.

Animal Testing Shows Promise for Clinical Use

To test the coating in live models, the team implanted coated and uncoated devices into mice and rats. In animals with uncoated implants, infections developed quickly, causing swelling and bacterial spread. In contrast, animals with coated implants remained healthy, with minimal signs of infection.

In another experiment involving wound healing in rats, coated dressings outperformed both untreated and overdose-control groups. The smart coatings promoted faster healing, with complete closure of the wound by day 15. Overdose coatings, while antibacterial, slowed healing due to excessive antibiotic exposure. This highlights the advantage of on-demand release over constant drug exposure.

Tissue analysis confirmed reduced inflammation and better tissue regeneration in the group treated with the smart coating. These findings support the idea that intelligent drug delivery improves healing outcomes while minimizing side effects.

Choose the right slot-die head for your application Read our guide to understand which slot-die head is right for you.

Conclusion

This study introduces a new generation of multifunctional coatings that combine antibiotic delivery, infection responsiveness, and real-time monitoring into a single material. The coating is easy to produce, can be applied to various surfaces, and is highly effective in fighting infection both in the lab and in living organisms.

The ability to monitor drug release visually and in real time opens new possibilities in wound care and implant safety. Clinicians gain more control over treatment decisions, and patients benefit from more precise care. For the coating industry, especially those using roll-to-roll or wet-coating systems, this represents a unique opportunity to deliver high-performance materials without reinventing the manufacturing process.

Authors

Haotian Li

Linjun Zhang

Bo Liang

Hongrui Xue

Huan Cao

Zhen Li

Lei Yang

Yiwen Li

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.