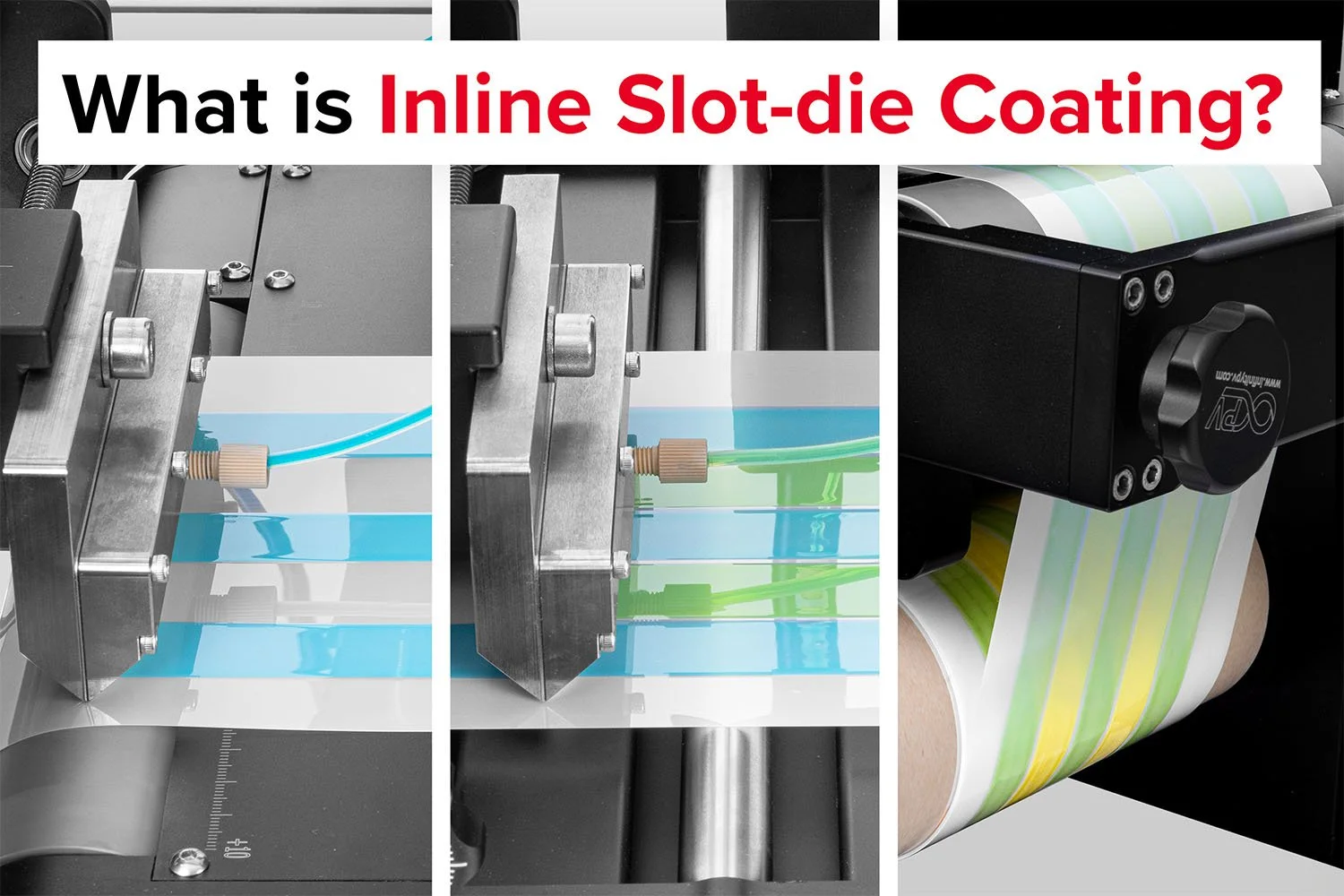

What Is Inline Slot-Die Coating? Wet-on-Wet and Dual Slot-Die Coating Explained

What is Roll-to-Roll Inline Processing?

Roll-to-roll (R2R) inline processing is a continuous manufacturing method in which a flexible substrate such as film, foil, paper, or fabric is unwound from a supply roll, passed sequentially through multiple processing stations (for example slot-die coating, printing, drying, curing, laminating, or inspection) while held under controlled tension and alignment, and then rewound onto a take-up roll.

Because the web moves continuously, processing steps are integrated in a single, synchronized line so material receives successive treatments without intermediate handling or storage; real-time controls for speed, tension, temperature, and inline inspection are used to maintain uniformity and yield over long runs.

Discrete processing, by contrast, treats individual sheets, panels, or parts in separate, often batch-oriented operations. Each process step is typically performed on distinct fixtures or machines, with parts loaded and unloaded between steps and possible intermediate storage. This approach suits rigid substrates, sheets, long dwell-time operations, or low-volume, high-mix production where frequent changeovers and individualized handling are required.

The practical differences stem from these core modes: R2R delivers much higher throughput and lower per-unit handling cost for flexible products that can be processed continuously, but it demands precise web handling, synchronized equipment, and robust inline processing, because defects can affect long lengths of material. Discrete processing offers greater flexibility for varied part geometries and simpler isolation of defects at the expense of higher handling, longer cycle times, and generally lower volume efficiency.

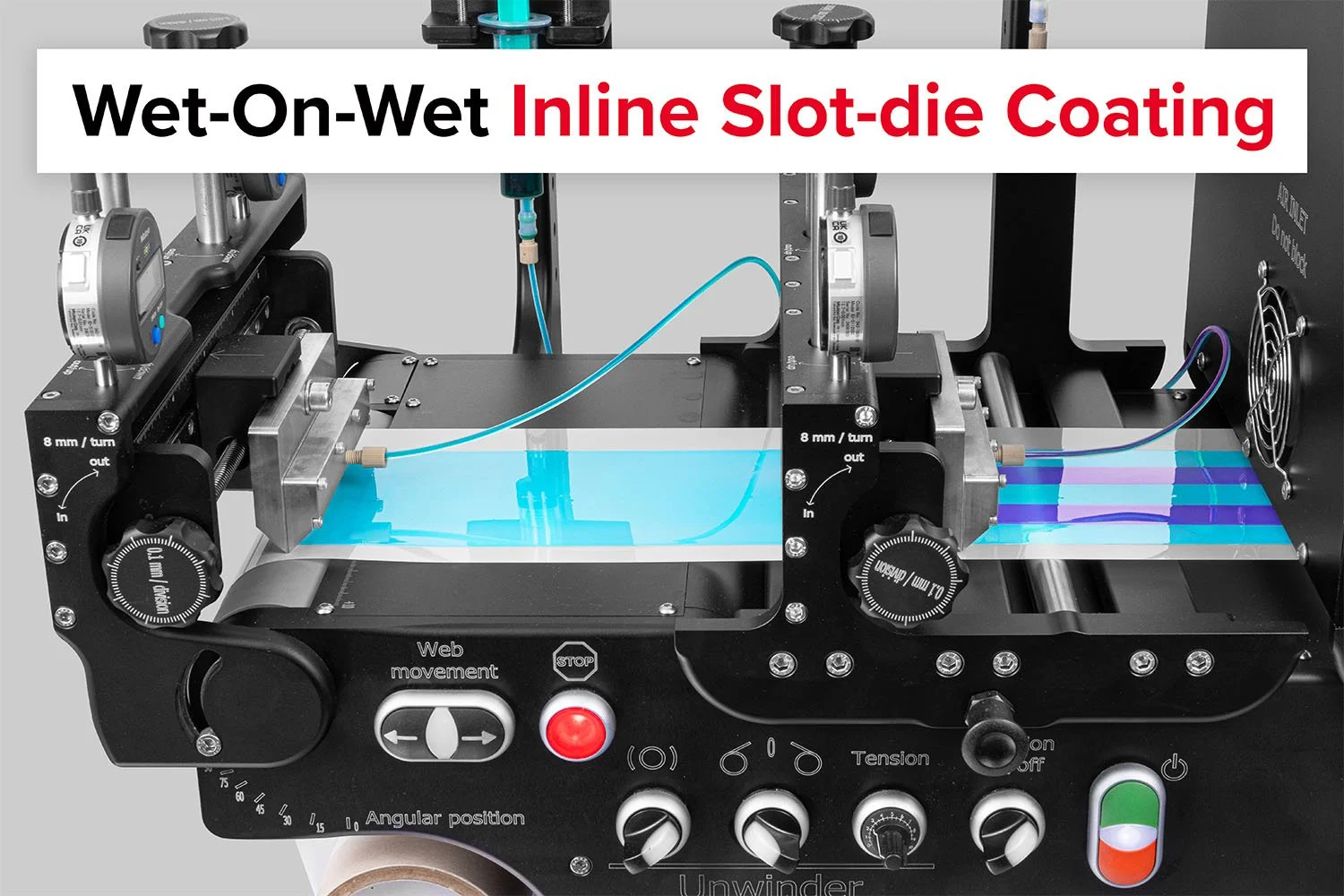

Inline Wet-on-Wet Slot-die Coating

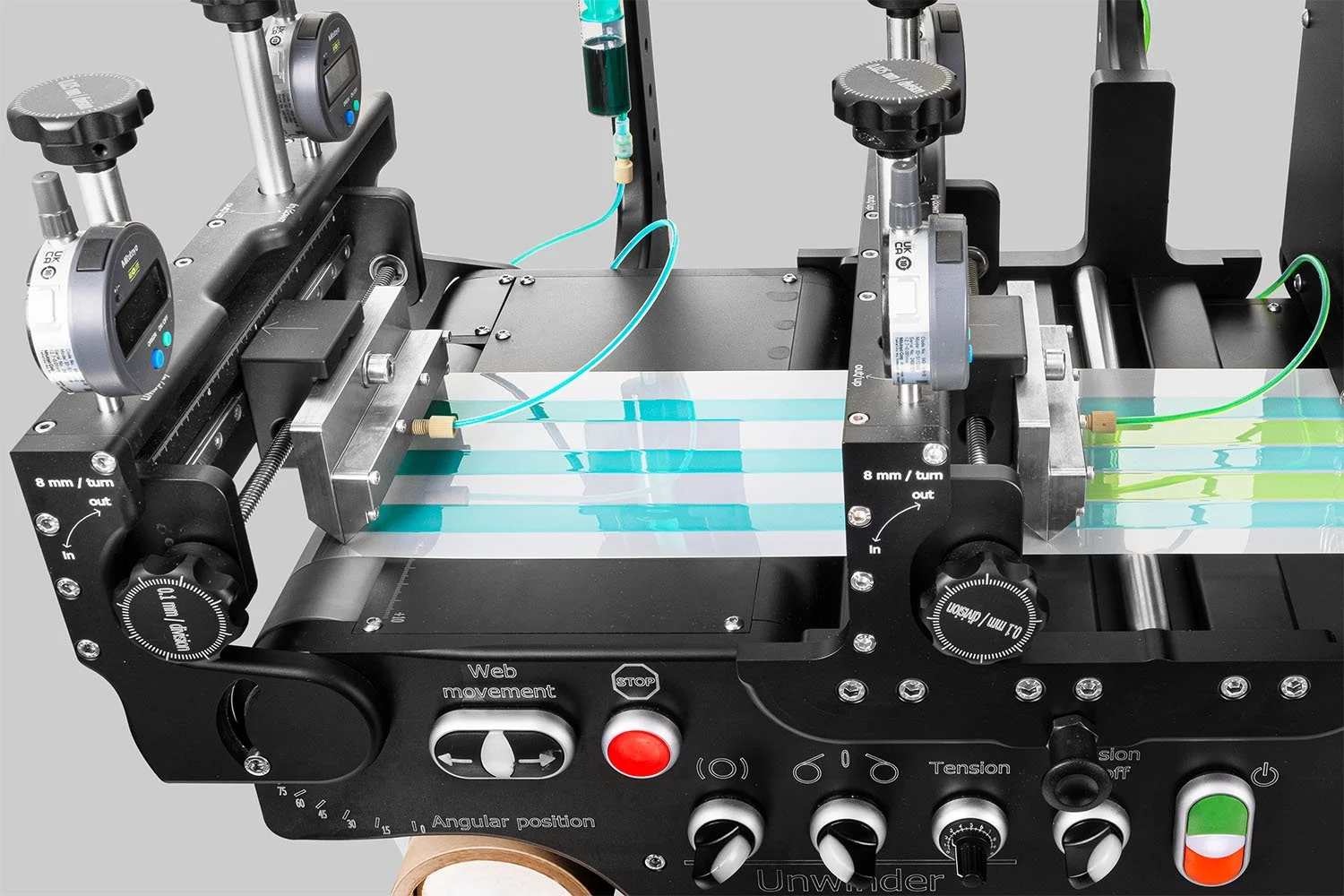

Using two slot-die stations on an R2R platform makes it possible to deposit a second wet film onto a first still-wet film (wet-on-wet) to form multilayer stacks, graded interfaces, or blended films without intermediate drying. In practice the web passes under the first slot-die, which deposits a precisely metered wet layer; the web then travels a short, controlled distance to the second slot-die where a second formulation is applied before the first layer has dried or gelled.

Key operational considerations are spacing and residence time between dies, formulation compatibility, and tight process control. The distance between dies (and the web speed) sets the wet-on-wet interaction time: short spacing and higher speed preserve greater intermixing, while longer spacing or slower speed allows partial leveling or viscosity increase of the first coat before the second is applied.

Formulation rheology and evaporation rates must be chosen so the first layer retains enough integrity to avoid catastrophic mixing but allows the intended degree of interdiffusion or adhesion. Solvent compatibility is critical: similar or mutually soluble solvents can produce graded interfaces or interdiffusion, while orthogonal solvent systems or rapid gelling chemistries can maintain sharper layer boundaries.

Control variables that must be coordinated across both slot-dies include individual flow rates (to set wet thicknesses), die-to-web gaps, web tension and downstream drying/curing profiles.

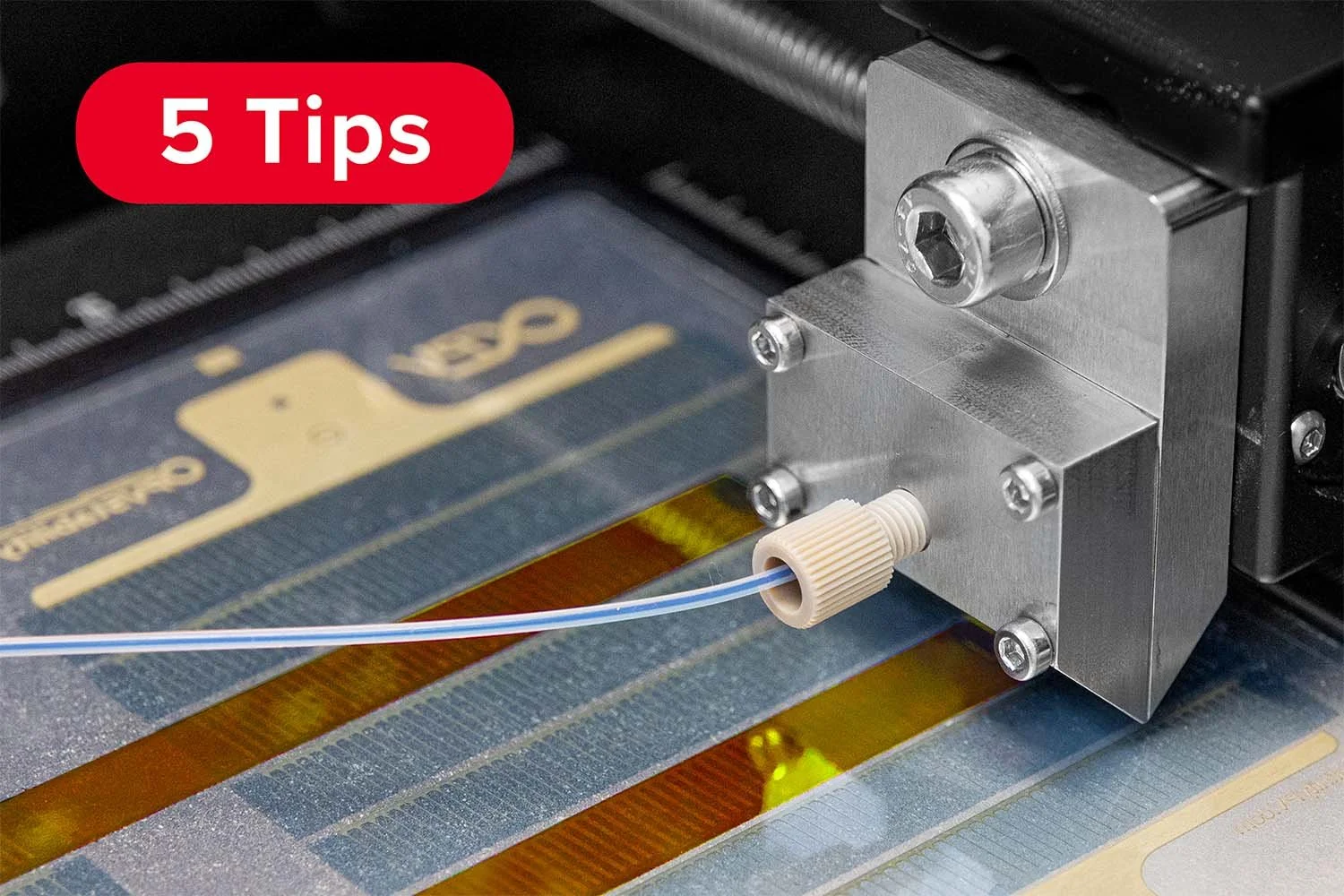

Dual Slot-die Coating

Inline dual slot‑die coating with intermediate drying employs two slot‑die stations on a roll‑to‑roll (R2R) line, with a controlled drying or curing step between the depositions. The first slot‑die deposits a precisely metered wet film; the web then passes through a dryer that solidifies or gels that layer to a specified state— before it reaches the second slot‑die head for the subsequent coating. This approach produces well‑defined interfaces with minimal interdiffusion, allows independent optimization of each formulation and thickness.

Inline R2R dual slot‑die coating with intermediate drying between two slot‑die stations.

Web handling — speed, tension, and registration — must be tightly controlled, as these parameters are common to both slot-die depositions and determine, among other things, the wet thickness of the slot-die coated layers and the drying time in each stage

Inline dual slot-die coating is a compelling choice when throughput and time-to-market matter: by applying two layers continuously on a single web with an intermediate drying stage, it eliminates unloading, re-fixturing, and batch handling, dramatically reducing cycle time and labour. The result is higher production rates and lower per-unit cost while preserving layer quality through controlled drying, minimizing contamination and rework. For products where scale, consistency, and rapid ramp-up are priorities, the speed advantage alone often justifies the investment in inline dual slot-die capability.

Your coating process is only as good as the slot-die head that delivers it. Our guide helps you evaluate your needs and choose the right slot-die head for optimal quality, efficiency, and cost-effectiveness. Read the selection guide here.

Conclusion

Inline slot-die techniques — wet-on-wet and dual slot-die with intermediate drying — give formulators and engineers precise levers to tailor interfaces, adhesion, and layer uniformity while shortening cycle time and reducing handling.

These gains require investment in accurate web handling, matched chemistries, robust drying/solvent management, and inline inspection, but when those elements are engineered together, R2R delivers faster scale-up, higher yield, and significant competitive advantage.

For teams targeting volume, repeatability, and rapid time-to-market, adopting R2R inline strategies is often the most effective path from lab formulation to reliable production.

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.