How to Select and Prepare Your Substrate for Roll-to-Roll Perovskite Solar Cell Manufacturing

It’s time to make perovskite solar cells!

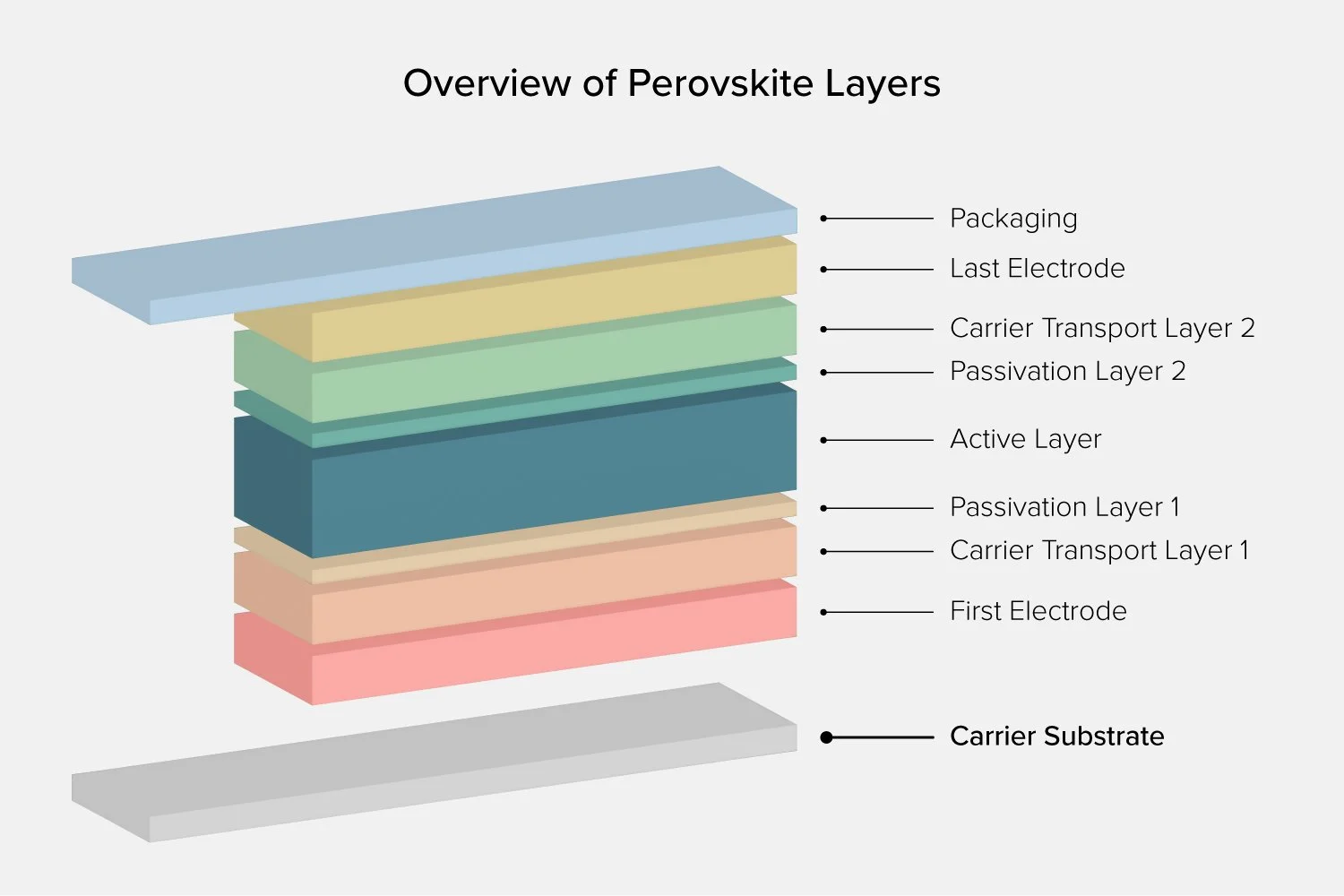

In this series, we’ll teach you how to make roll-to-roll (R2R) perovskite solar cells from start to finish. We’ll walk you through every layer of the solar stack and every process step, giving you the knowledge you need to reproduce the work yourself—and even take it further with your own ideas.

We’ve designed the process around compact laboratory equipment, so you can produce many square meters per run, all within a regular lab setup.

In this episode, we’ll focus on how to select and prepare your carrier substrate for coating. You’ll see how to handle everything from bare PET foil to barrier materials, or PET with a pre-existing electrode, and get your substrate ready for the high-quality layers that follow.

This episode focuses on how to select and prepare your carrier substrate.

The Carrier Substrate

Roll-to-roll processing of flexible perovskite solar cells starts with a carrier substrate, which is most typically a polyethylene terephthalate, or PET, plastic material that has excellent optical and thermal properties.

For many printed solar cells, the process starts with printing the first electrode, but for perovskites the carrier substrate already has a layer of semitransparent conducting oxide on it, such as indium tin oxide, or ITO for short.

Whether you are starting from pure PET or PET/ITO, you will need to prepare it for the following steps, which we will detail in the next videos of this series.

Cleaning Methods

The active layers that you are about to apply will require that the substrate is clean and possibly patterned such that the junctions formed in the ensuing steps are correctly interconnected.

Cleaning can be carried out in a number of ways.

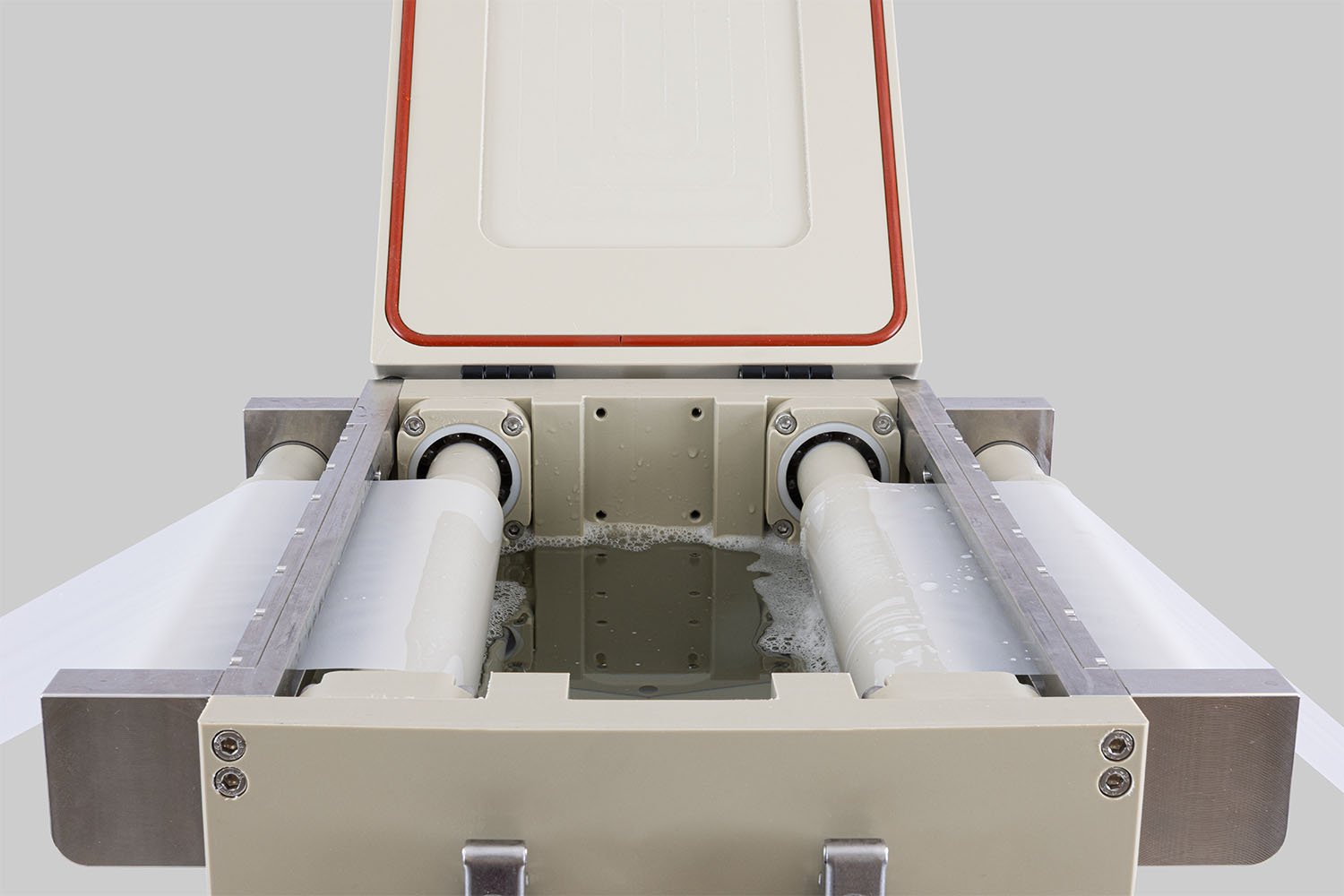

One option is contact cleaning using a system where a rubber roller, which tends to pick up dust, is rolled over your substrate and then over an adhesive roller where the dirt and particles are removed as they build up.

In the case of pure PET, there is a strong tendency for static charges to build up, which can really affect your coating or printing. Here, an antistatic bar is a very useful tool. In the case of conducting ITO, this is normally not needed.

Example of surface treatment.

Surface Treatment

Again, in the case of pure PET with a low surface energy, it can be useful to treat the surface with corona or plasma. This process generates reactive gas molecules that undergo a chemical reaction with the surface in addition to “burning” off impurities. It effectively increases the surface energy of the substrate (sometimes briefly), which enables you to make a good, well-defined coating or printing that typically results in strong adhesion. With conducting surfaces such as ITO, this is normally not necessary or recommended, as these treatments can destroy the ITO properties.

Other options are washing the substrate with a chemical, a solvent, or soapy water to obtain a clean surface.

It is also possible to acquire foil that has what is known as a pristine clean surface (PCS), where it has been covered with a plastic liner to keep it completely clean during all handling after manufacture. This liner can be stripped from the surface immediately prior to coating, thus ensuring complete control over your ITO surface until you need it.

Example of chemical bath.

Example of Pristine Clean Surface Coating.

One aspect of preparing your substrate in the case of ITO is patterning the ITO by laser scribing, where you selectively remove the conducting ITO in a specific pattern matching your desired electrode structure.

This is best carried out with a laser wavelength where ITO absorbs and where the PET substrate does not absorb as much. It is thus possible to convert your fully covering ITO surface into electrically isolated lines or islands of ITO.

This can also be achieved by printing or coating an etch resist onto the ITO, followed by etching, stripping the resist, washing, and drying.

Patterning the ITO by laser scribing.

Conclusion

Successful roll-to-roll fabrication of perovskite solar cells begins long before the first functional layer is coated. Substrate selection, cleaning, electrostatic control, surface treatment, and electrode patterning all play critical roles in determining device quality and scalability.

By carefully preparing your PET or PET/ITO substrate, you create the foundation for uniform coatings, reliable interconnection, and high-performance devices.

In the next step of the process, attention shifts to the first functional layer — typically a charge-selective layer — which we will cover in detail in the following article.

Other Videos in This Series:

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Articles

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater. A compact, fully integrated R2R coater that fits on a workbench, in a fume hood or a glovebox.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.