Roll-to-Roll Battery Manufacturing: Slurry vs Dry Coating in Scalable Battery Production

Can Scalable Electrodes Unlock the Future of EV Batteries?

A recent article titled "Upscaling high-areal-capacity battery electrodes", published in Nature Energy, addresses a critical gap in the race for better batteries. While academic researchers have long focused on inventing novel materials to improve performance, this article pivots attention to something far more scalable: how we design and manufacture electrodes.

Rather than chase ever more exotic chemistries, the authors propose a practical, impactful solution. By increasing the areal capacity of electrode sheets using scalable roll-to-roll (R2R) manufacturing processes, we can achieve better energy density, lower production cost, and improved performance, all while using existing materials and technologies.

If you're part of the battery manufacturing industry or researching next-generation energy storage, this article outlines a structured, industrially viable pathway from lab-scale innovation to factory-floor production.

Key Highlights

High-areal-capacity electrodes can raise battery energy density and cut costs without needing new materials

Roll-to-roll techniques like slurry casting and dry coating are viable at industrial scale

Dry coating removes the need for solvents, improving safety and lowering costs by up to 15 percent

Increasing areal mass from 15 to 35 mg/cm² reduces manufacturing energy by 25 percent

Specific energy improves by 14 percent through higher areal capacity, a gain comparable to advanced cathode chemistries

Optimizing structure (porosity, tortuosity, conductivity) is crucial for thick electrode performance

Challenges like electrode cracking, delamination, and uneven drying are manageable with thoughtful design and process control

Applicable across chemistries, including lithium-ion, sodium-ion, and all-solid-state batteries

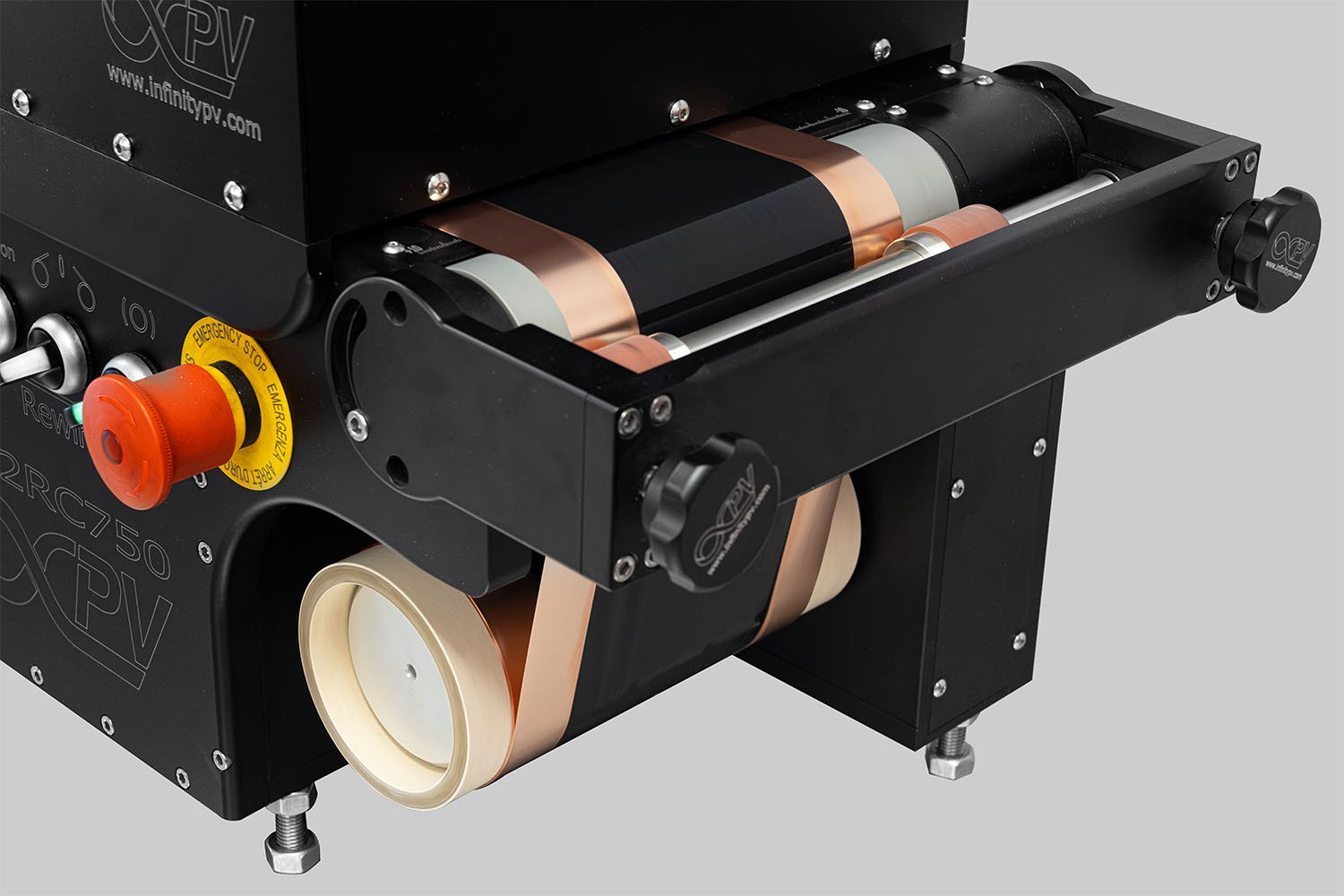

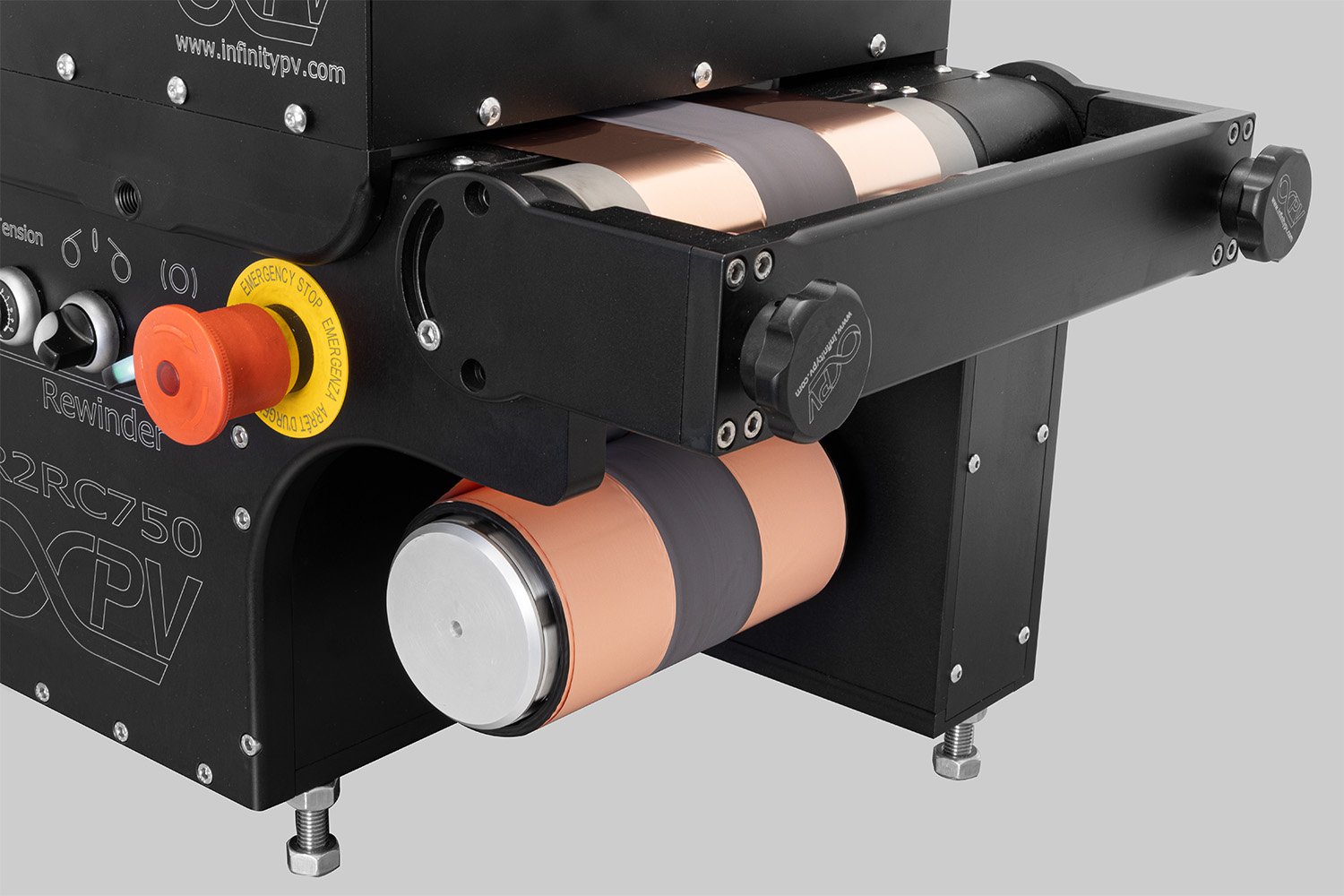

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

What Are High-Areal-Capacity Electrodes and Why They Matter for Scalable Battery Design

Areal capacity refers to how much active material is loaded onto each square centimeter of electrode surface. In the past, researchers aimed to boost performance by tweaking the chemistry of individual materials. But that path is increasingly constrained by fundamental limits.

By increasing the thickness of the electrode while maintaining its structural and electrochemical performance, manufacturers can produce batteries with significantly higher energy density. This approach reduces the number of inactive layers like separators and current collectors, which lowers both weight and cost.

The article shows that doubling the areal mass of the cathode from 15 to 30 mg/cm² delivers the same energy boost as increasing the cathode’s specific capacity from 200 to 300 mAh/g, a figure that is rarely achievable with current materials. This means more energy per kilogram and fewer compromises at the cell level.

Why This Article Changes the Battery Manufacturing Conversation

The industry's main goals for EV batteries are clear: improve energy density, reduce cost, and make cells easier to manufacture. High-areal-capacity electrode design addresses all three.

Using the BatPaC cost modeling tool, the authors demonstrate that scaling areal capacity can reduce cell cost by up to 14 percent, cut electrode processing energy by 25 percent, and shrink the overall manufacturing footprint. More importantly, these gains are not theoretical. They are based on simulations and analysis of current lithium-ion battery chemistries such as NMC811. This makes the article particularly relevant to companies that need solutions deployable within current production capabilities.

The Slot-die Coater is an excellent choice for researchers focused on developing and optimizing battery electrode slurries at the laboratory scale.

Slurry Casting and Dry Coating in R2R Manufacturing

Slurry casting is a well-established method that mixes active materials with solvents and binders. The resulting slurry is applied to a current collector and then dried. While scalable and widely used, increasing electrode thickness can lead to drying inhomogeneities, cracking, and poor adhesion. Binder and conductive additive migration during drying can create uneven charge distribution and reduce efficiency.

Dry coating eliminates the solvent stage. It involves mixing dry powders and mechanically forming a self-supporting film, which is pressed onto the current collector. This simplifies the process, reduces environmental impact, and avoids many defects associated with drying. However, uniform dispersion of powders and achieving consistent adhesion remain technical challenges that must be addressed for successful implementation.

How Electrode Thickness, Porosity, and Conductivity Affect Energy Delivery

One of the most important insights from the article is how transport behavior changes as electrodes get thicker. In thinner electrodes, the paths for electrons and ions are short, so resistance is minimal. In thicker electrodes, increased resistance from both ion and electron transport can hinder performance.

The authors use simulations to show that under practical conditions, only 76 percent of the theoretical capacity of a 45 mg/cm² electrode is used during charging, compared to nearly 100 percent for a 15 mg/cm² electrode. This is due to limitations in ion transport, not material quality.

Managing this performance drop requires careful engineering of electrode porosity and tortuosity. Vertically aligned pore structures, multilayer designs with different particle sizes, or optimized additive distribution can help maintain effective charge transport even in thicker electrodes. The goal is to balance high areal capacity with uniform, efficient transport across the entire thickness of the electrode.

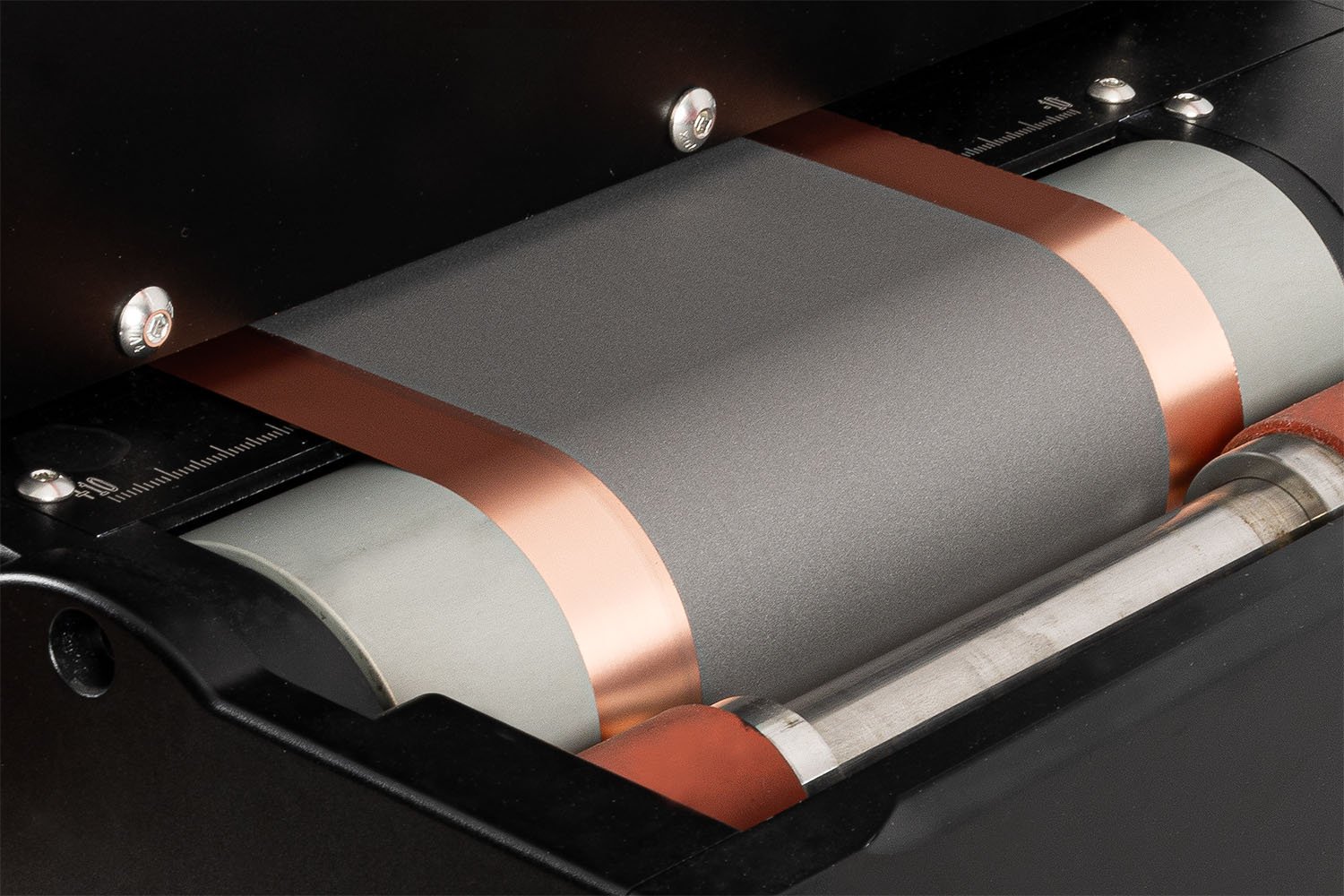

Double-sided battery coating on a Laboratory Roll-to-Roll Coater.

Materials Chemistry as a Design Tool for Manufacturable Electrodes

This article outlines a comprehensive strategy to optimize materials chemistry for scalable, high-performance electrode production.

For active materials, mechanical durability is crucial. Materials must withstand calendering pressure without cracking. Approaches like grain-boundary engineering, concentration gradient design, or using single-crystal structures improve mechanical integrity. Larger particles help reduce tortuosity, but their shape and packing also matter for conductivity and density.

Binders play multiple roles beyond simply holding components together. Their toughness influences cracking during drying and bending. Their polarity and surface chemistry affect how well they interact with additives and electrolytes. High-performance binders must balance flexibility, adhesion, and chemical compatibility with other components.

Conductive additives ensure good electron transport. One-dimensional additives such as carbon nanotubes provide excellent conductivity at low volume fractions but are difficult to disperse uniformly. Adjusting surface energy or aspect ratio helps integrate these additives more effectively into the electrode matrix.

Current collectors provide the structural foundation and must adhere strongly to electrode layers. Roughening the surface or applying primers improves mechanical anchoring. Collectors also affect thermal management. As areal capacity increases, the number of current collector layers decreases, which can reduce in-plane heat dissipation and raise thermal risk. Choosing high-conductivity materials or adding flame retardants can improve safety and reliability.

Industrialization Strategies for High-Areal-Capacity Electrodes

Scaling high-areal-capacity electrodes involves tuning each step of the roll-to-roll manufacturing process. For slurry casting, slurry formulation must prevent binder migration and cracking during drying. Multistage or infrared drying can improve uniformity. Calendering pressure and speed must be optimized to prevent delamination and preserve adhesion.

Dry coating processes require control over binder fibrillation and particle dispersion. Mixing time and mechanical energy must be carefully calibrated to achieve consistent films.

Multi-layer coating, now used in commercial lines, allows each layer to be customized for performance. For example, placing smaller active particles in the top layer improves diffusion while larger particles in the bottom layer reduce tortuosity. Targeting a cathode density above 3.2 g/cm³ is difficult but possible with structured designs and controlled binder content.

N/P ratio, electrolyte viscosity, and electrode wetting must all be optimized in parallel. Thicker electrodes make electrolyte infiltration more difficult, particularly at large coating widths. Designing electrolyte systems that balance infiltration speed with conductivity is essential. Electrolyte injection techniques and capillary conditioning processes can help address these scale-up challenges.

Need a slot-die head? We’ve got you covered.

Beyond Lithium-Ion: Broad Applicability Across Chemistries

The principles explored in this article are not limited to lithium-ion technology. Sodium-ion batteries and all-solid-state batteries also benefit from higher areal capacity. For sodium-ion systems, the challenges of thick hard carbon anodes and slow ion diffusion require similar design strategies.

All-solid-state batteries may overcome some limitations through their solid electrolytes, but bring new manufacturing complexities such as sintering and atmospheric control. Even so, the areal capacity concept still applies and can help improve cell-level energy metrics in these emerging technologies.

Conclusion: From Lab to Line with Smarter Electrode Design

This article offers a roadmap for bridging the gap between innovative battery research and industrial-scale production. By focusing on areal capacity and using roll-to-roll compatible methods like slurry casting and dry coating, manufacturers can make better batteries using materials that already exist.

This shift in design focus could help meet the energy and cost targets needed to accelerate EV adoption and support the global transition to electrified transportation. It reminds us that in battery manufacturing, smart design often matters more than exotic chemistry.

Authors

Jung-Hui Kim

Nag-Young Kim

Zhengyu Ju

Young-Kuk Hong

Kyu-Dong Kang

Jung-Hyun Pang

Seok-Ju Lee

Seong-Seok Chae

Moon-Soo Park

Je-Young Kim

Guihua Yu

Sang-Young Lee

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater, featuring a syringe pump, a 65 mm slot-die head, and an infrared oven for precise lab coating.