Industry and Company News

Discover our latest updates on product launches, industry news, and event highlights.

Stay informed with straightforward insights and behind-the-scenes glimpses.

Roll-to-Roll Battery Manufacturing: Slurry vs Dry Coating in Scalable Battery Production

This article reviews a landmark study showing how roll-to-roll methods and electrode design improvements can scale battery manufacturing, cut costs, and boost energy density without new materials.

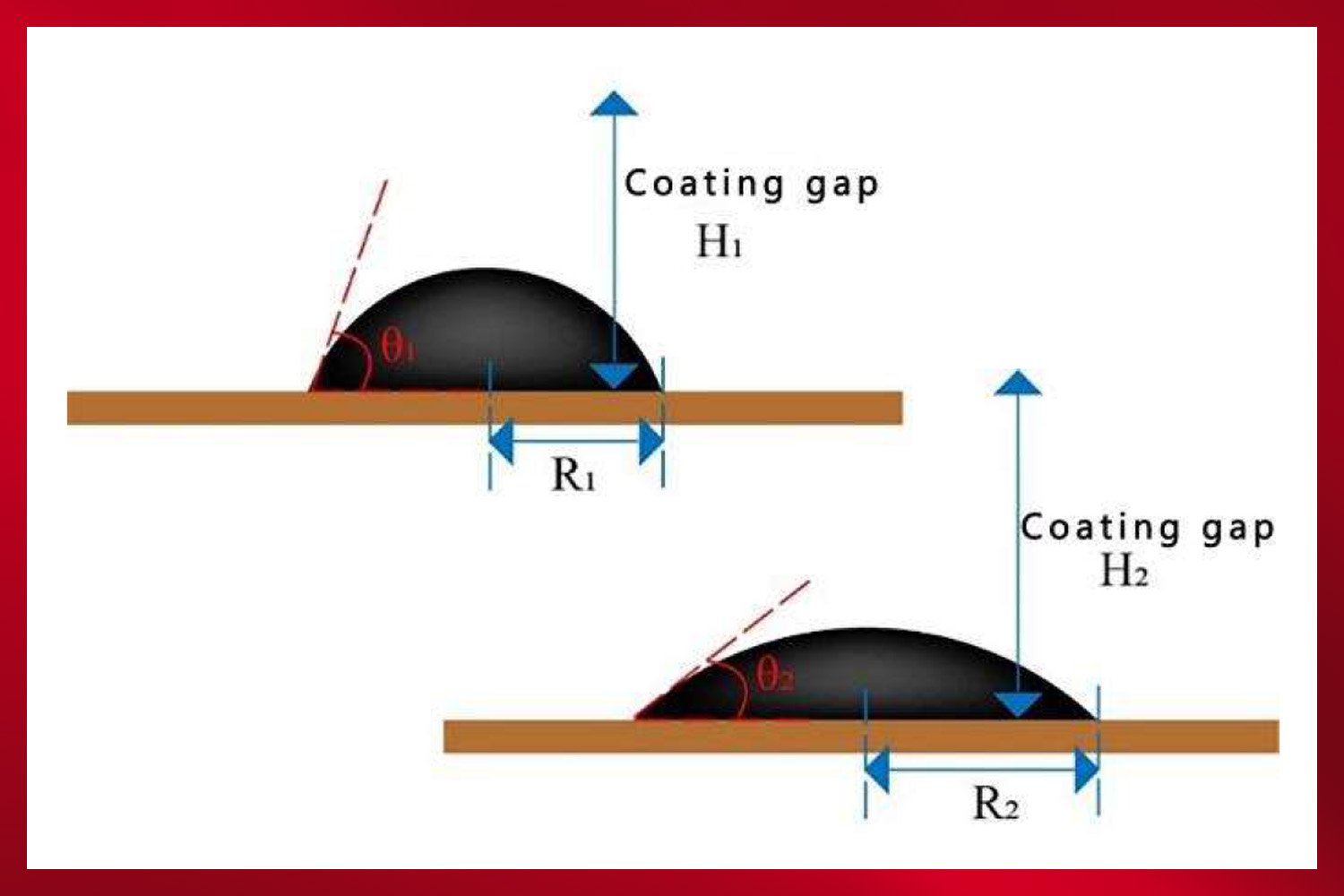

How Roll-to-Roll Coating Parameters Impact Lithium-Ion Battery Performance

A new study shows how calender gap and roller speed influence the film formation in semidry electrode production for lithium-ion batteries, improving efficiency and performance.

From Lab to Gigafactory: How Battery Manufacturing Equipment and Slot-die Coating Shapes the Gigafactory Landscape

Discover how cutting-edge manufacturing equipment is driving cost efficiency, sustainability, and innovation in lithium-ion battery gigafactories, based on a recent review by researchers from Concordia University.

Breakthrough in Lab-Scale R2R Coating: Optimizing Drying With Dual-Sided Sensor

Discover how chromatic confocal sensors enhance drying process control in lab-scale roll-to-roll battery electrode manufacturing with real-time thickness and roughness data.

Optimizing Meniscus Behavior in Slot-Die Coating Using Temperature Control: New Insights on Temperature-Controlled Slot-Die Coating

A new study shows how heated substrates improve slot-die coating stability and reduce defects in lithium-ion battery electrode films—ideal for lab-scale R2R engineers.

Optimizing Slot-Die Coating for Fuel Cells: New Research Improves Catalyst Ink and Electrode Performance

Researchers investigate how slot-die coating and catalyst ink formulation can improve manufacturing of PEM fuel cell electrodes. Results show better coating quality and MEA performance with optimized parameters.

Slot-Die Coating in Battery Production: Why Slurry Rheology Matters

A new study explores how the flow properties of battery electrode slurries affect manufacturing outcomes and performance, offering insights for process optimization.

Improving Roll-to-Roll Slot-die Coated Perovskite Solar Cell Efficiency with PEDOT:PSS-PTAA Coatings: Insights from XPS Mapping

This breakthrough in perovskite solar cell technology improves efficiency through a dual-layer hole transport strategy, enabling scalable roll-to-roll manufacturing.

infinityPV partners with JP Kummer to Expand R2R Coating Equipment Offering in Europe

We're thrilled to announce our new partnership with JP Kummer, a leading distributor in semiconductors, photovoltaics, microelectronics, and life sciences.

Breakthrough in R2R Slot-die Coating: Coating Quality Now Predictable in Real Time

Discover how a new study predicts coated layer thickness in roll-to-roll processes using meniscus shape analysis and machine learning.

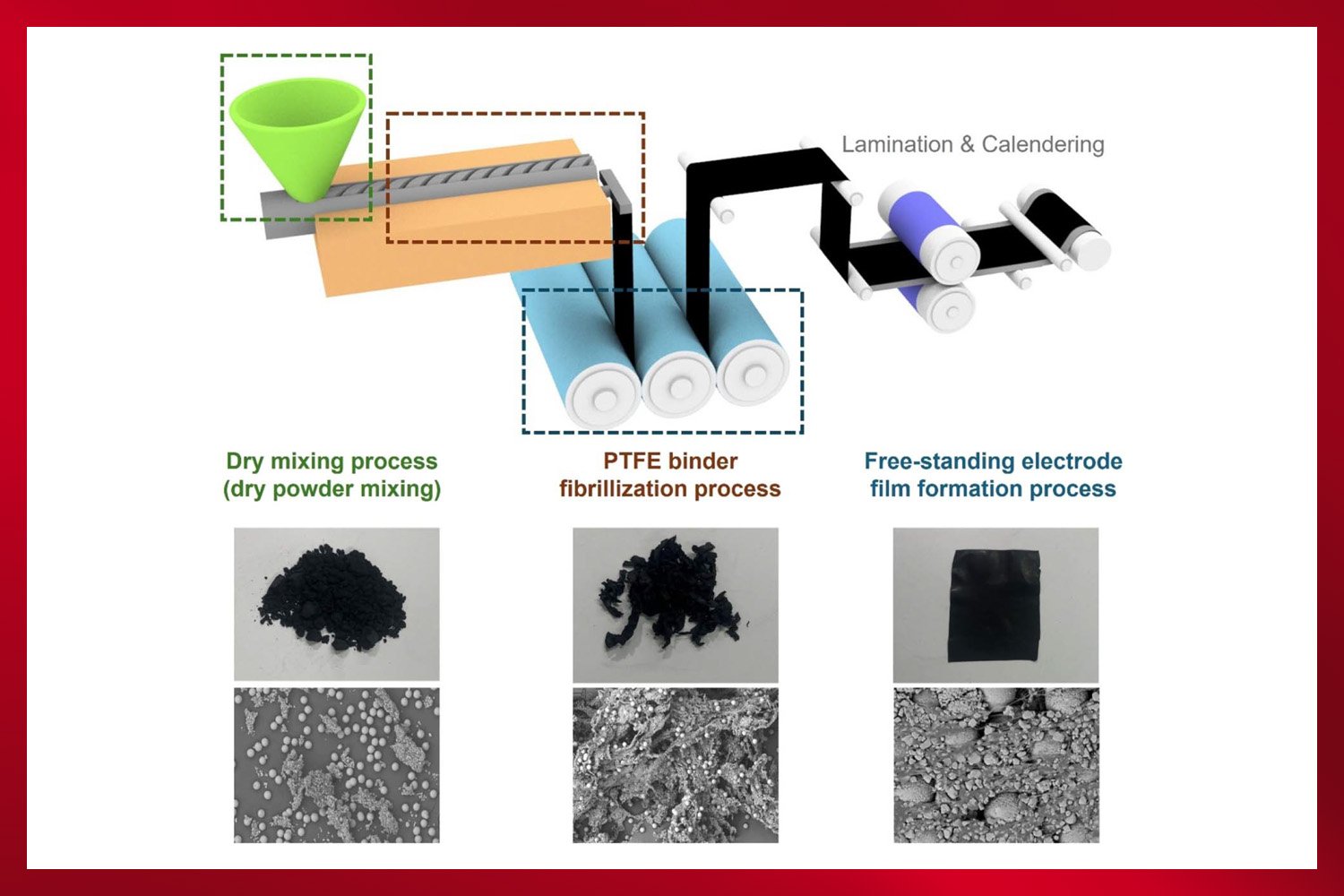

Roll-to-Roll Dry Coating: A Scalable, Sustainable Future for Lithium Battery Manufacturing

A recent study highlights the roll-to-roll dry coating process as a scalable, sustainable alternative to conventional battery electrode manufacturing, addressing key challenges in energy density, cost, and environmental impact.

Slot-Die Coating: A Scalable Pathway to Commercial Perovskite Solar Cells

Researchers present a detailed review of 115 studies on slot-die-based perovskite solar cells, highlighting how this scalable coating technique holds the key to commercializing next-gen solar technology.

Enhancing Slot-Die Coating with Corona Treatment: infinityPV and Tantec Join Forces

At infinityPV, we are thrilled to announce our new collaboration with Tantec, a leader in innovative surface treatment technologies.

Game-Changer for Slot-Die Coating: New Model Predicts Lithium Battery Electrode Thickness with 98.75% Accuracy

Researchers have developed and validated a model that predicts lithium battery electrode coating thickness with high accuracy, helping manufacturers reduce waste and optimize performance.

Revolutionizing Lithium-Ion Battery Manufacturing: Dry Processing, 3D Printing & Slot-Die Coating

Traditional lithium-ion battery manufacturing relies on energy-intensive slurry-based processing. However, innovations like dry processing, radiation curing, and 3D printing are transforming electrode production—offering higher efficiency, lower costs, and improved sustainability.

How Do Organic Batteries Work? A Deep Dive into the Latest Research

Organic batteries offer a sustainable alternative to lithium-ion technology. A new study explores their mechanisms, advantages, and challenges in energy storage applications.

Breakthrough in Perovskite Solar Cell Stability: Atomic Layer Deposition Enhances Longevity

A recent study demonstrates that applying an ultrathin atomic layer deposition (ALD) coating to perovskite solar cells dramatically improves their long-term stability. This innovation could help bring perovskite technology closer to widespread adoption.

Breakthrough in Fuel Cell Research: Graded Roll-to-Roll Slot Die Coating Accelerates Catalyst Development

A new study demonstrates how roll-to-roll slot die coating with the Laboratory Roll-to-Roll Coater enables high-throughput catalyst layer optimization for fuel cells. This method streamlines material development, reduces waste, and accelerates PEMFC research by producing graded catalyst layers in a single, continuous coating process.

Groundbreaking Hydrogel System Significantly Improves Solar Cell Efficiency Through Passive Cooling

Scientists have developed a lightweight hydrogel system for passive solar cell cooling, achieving a 23°C temperature reduction and boosting efficiency by 12.3%. Learn more about this innovative approach to solar energy optimization.

Overcoming Challenges in Roll-to-Roll Manufacturing: A Comprehensive Review of System Modeling and Control

A new review explores the latest advancements in roll-to-roll (R2R) manufacturing, focusing on system modeling and advanced control strategies. As precision demands increase in industries like flexible electronics and battery production, this review highlights key challenges, emerging solutions, and future research directions for optimizing R2R processes.

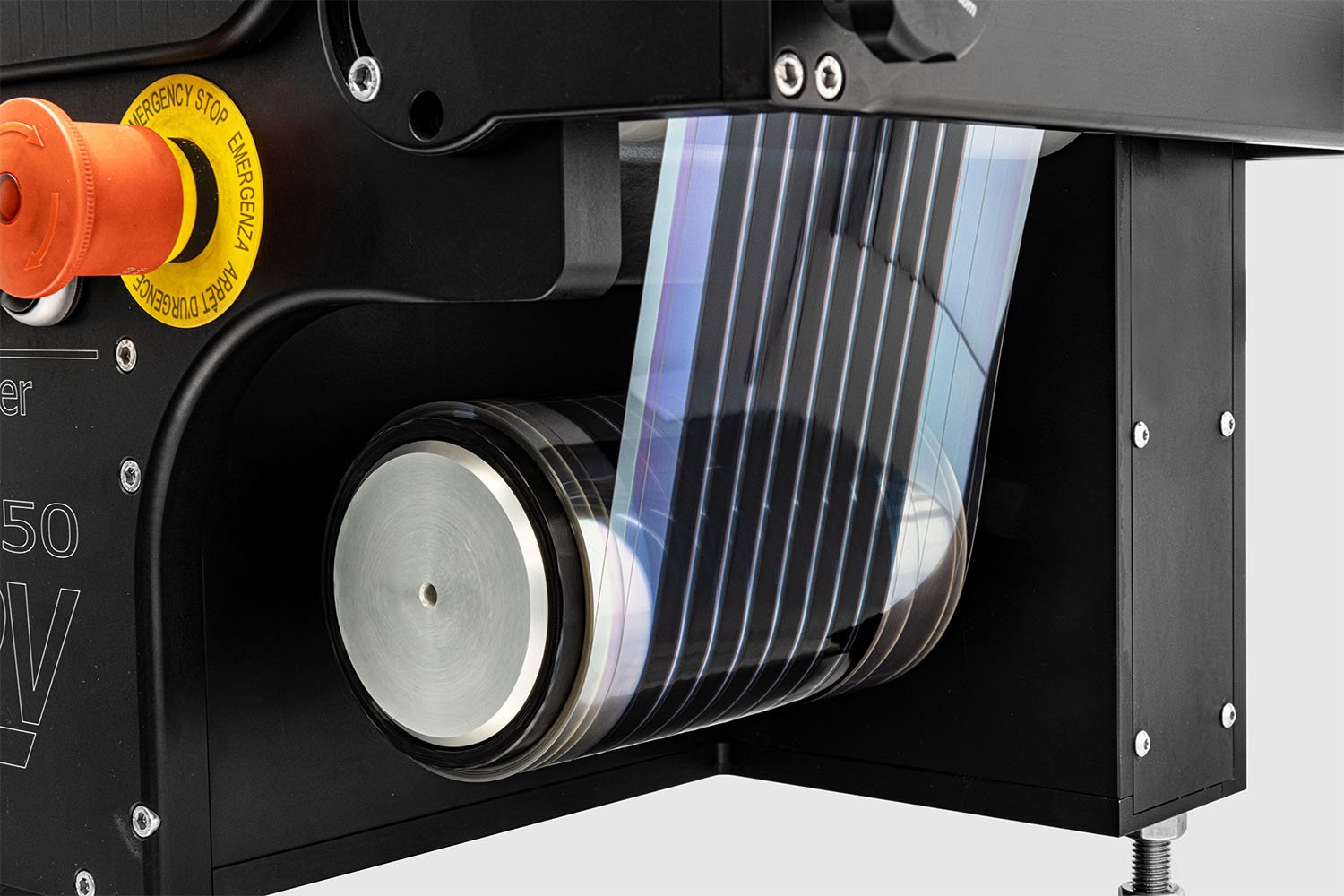

Build Your Own R2R Lab Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.

Related Pages

Processing Equipment

We offer comprehensive solutions for printed electronics manufacturing, from small-scale prototyping to large-scale Roll-to-Roll production.

Characterization Equipment

infinityPV equipment is proven instrumentation for the purpose of characterizing and/or testing photovoltaic films, single junction devices and modules.