Laboratory Roll-to-Roll Coater Accelerates Fuel Cell Catalyst Discovery

The Laboratory Roll-to-Roll Coater from infinityPV is designed to bring research precision and real-world scalability into the lab. More than just a tool for coating thin films, it provides scientists with a platform to explore advanced materials efficiently and reproducibly.

In a recent peer-reviewed study published in ChemElectroChem, researchers at the Helmholtz-Institute Erlangen-Nürnberg and Friedrich-Alexander-Universität Erlangen-Nürnberg demonstrated how the coater enabled breakthroughs in fuel cell technology. Their work showed that the machine can deliver reliable high-throughput coatings that accelerate the optimization of catalyst layers for proton exchange membrane fuel cells (PEMFCs) — a cornerstone of hydrogen fuel and hydrogen power applications.

Why the Study Was Conducted

Fuel cells are central to the future of hydrogen fuel and hydrogen power, offering a clean and efficient way to generate electricity without harmful emissions. A key component of this technology is the proton exchange membrane fuel cell (PEMFC), which relies on precisely engineered catalyst layers. Traditionally, optimizing these layers has required many separate experiments, each with different coatings and parameters. The Laboratory Roll-to-Roll Coater changes this approach by enabling graded slot die coating, where multiple variations can be produced in one continuous run.

How the Laboratory Roll-to-Roll Coater Was Used

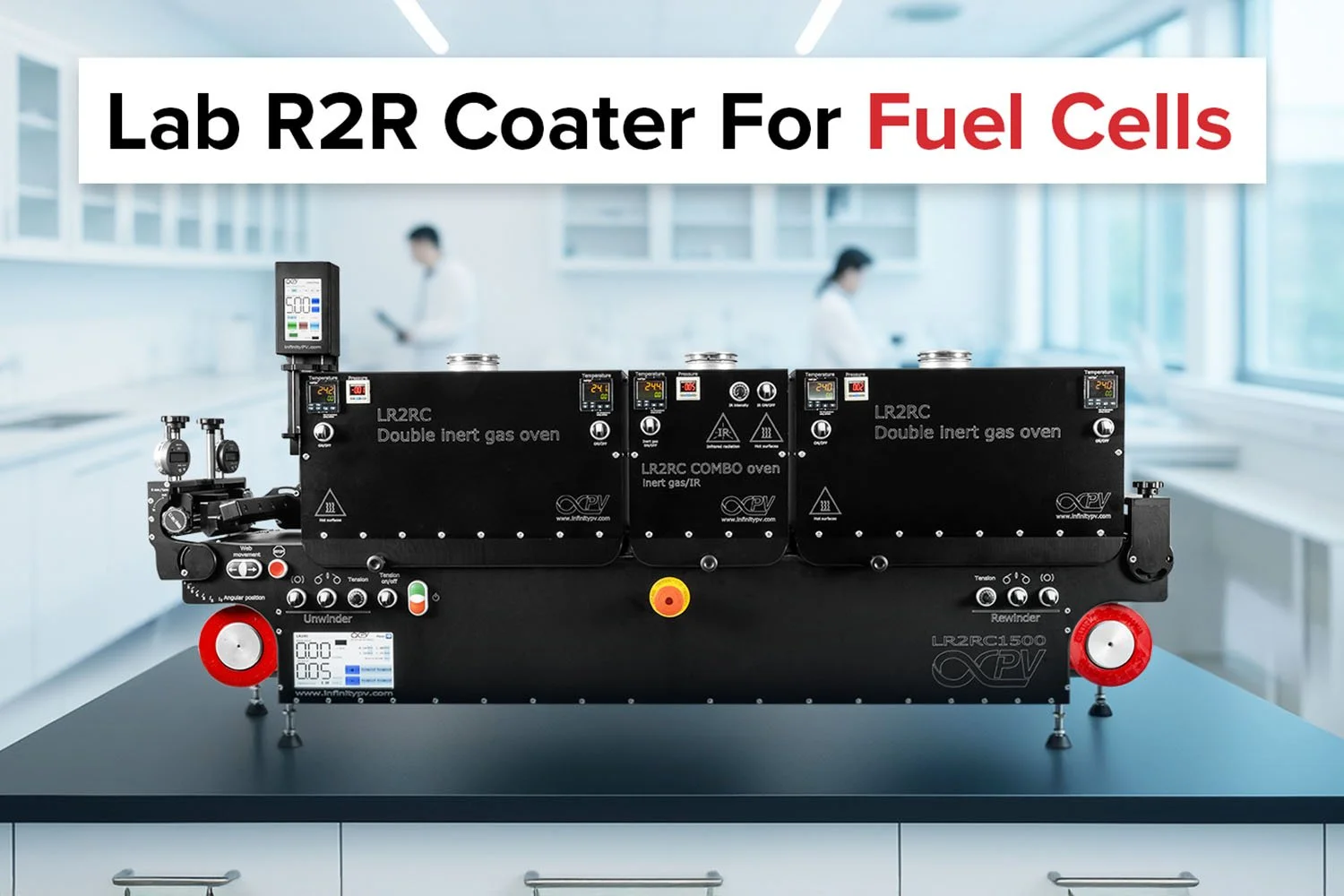

The team used the infinityPV LR2RC1500 coater, equipped with a 50 mm slot die head. A platinum-based catalyst ink was deposited onto PTFE foil while the ink flow was gradually reduced during the run. This process created a smooth gradient in film thickness, and therefore in catalyst loading, across the coated substrate.

To ensure precision, the setup included in-line confocal sensors for wet film thickness monitoring and X-ray fluorescence (XRF) to confirm platinum distribution. The result was a graded coating that could be cut into test samples representing different catalyst loadings without the need for multiple separate coatings. The graded film was then cut into sections, each corresponding to a different catalyst loading, and tested directly in full proton exchange membrane fuel cells.

Key aspects included:

In-line monitoring: Confocal sensors measured film thickness during coating for quality control.

Cross-validation: X-ray fluorescence (XRF) confirmed platinum distribution across the gradient.

Reproducibility: Multiple runs produced consistent results that are essential for credible scientific work.

What This Means for Your Research

If you are considering whether the Laboratory Roll-to-Roll Coater is the right choice for your lab, this study provides compelling evidence. The machine allowed researchers to produce high-quality graded thin films in a single run, monitor coatings with precision in real time, and generate reproducible results that stood up to the scrutiny of peer-reviewed publication. At the same time, the approach accelerated the pace of discovery while reducing material use and experimental workload.

For scientists working in fuel cell technology, hydrogen fuel systems, or other thin-film energy applications, the Laboratory Roll-to-Roll Coater offers both credibility and flexibility. Its use in published research demonstrates that it is not only a machine with impressive specifications but also a proven tool that supports real advances in the global shift toward clean energy.

How can we help with your research?

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.