Roll-to-Roll Coater Advances Trusscore’s Research in Electrochromic Coatings

Overview

Trusscore is redefining building materials through the fusion of sustainable PVC products and advanced nanotechnology. Their panels, suitable for residential, commercial, and agricultural applications, are strong, lightweight, easy to install, and highly durable. With a commitment to material science innovation, Trusscore is exploring new frontiers, including electrochromic wall panels that can change color on demand.

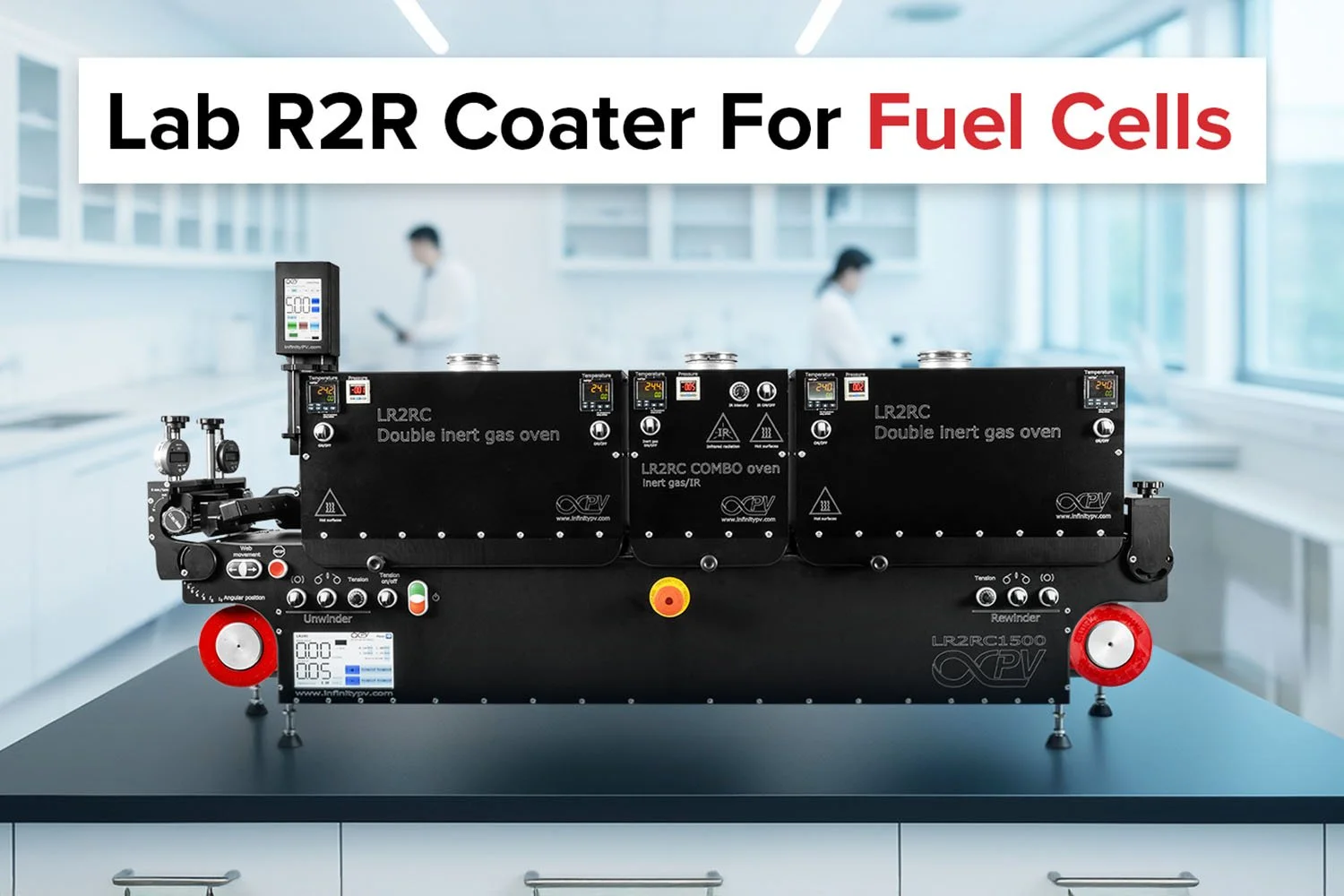

To advance this research, Trusscore adopted the Laboratory Roll-to-Roll Coater from infinityPV to enable precise thin-film fabrication and testing of their electrochromic materials.

Challenge

Developing color-changing panels requires highly controlled coating processes to ensure uniformity and reproducibility. Trusscore needed a laboratory solution capable of providing accurate web tension and control, consistent deposition of functional inks, and flexible, modular drying and curing options.

What Trusscore’s Scientists Say

Chat Smithson, Materials Scientist at Trusscore, shared his experience using the Laboratory Roll-to-Roll Coater:

"The Laboratory Roll-To-Roll Coater has indeed proven itself reliable for our requirements. We've found the web control feature to be particularly impressive, offering seamless adjustment. The slot-die heads have performed admirably, presenting no issues thus far. Regarding the heating unit, it's both user-friendly and easy to detach and reattach.

While the UV unit functions effectively, we believe an adjustable power level feature would enhance its versatility. A standout characteristic of the system is the ease with which the heat and UV stations can be removed and reattached. Overall, we are highly satisfied with the unit's performance. It offers exceptional web tension and control, and the heat and UV units function precisely as expected. The slot-die print heads consistently deliver high-quality, repeatable results from run to run.

Furthermore, our experience with ordering and shipping from your company, based in Canada, was seamless. Jon, our sales representative, was transparent and easy to collaborate with throughout the process. Shipping occurred within a reasonable timeframe of approximately 4-6 weeks, with subsequent orders for small parts like shims arriving promptly within 2 weeks."

— Chat Smithson, PhD, Materials Scientist at Trusscore

Summary

The Laboratory Roll-to-Roll Coater has enabled Trusscore to advance their electrochromic research with precision and consistency. The system’s high-quality slot-die coating, reliable web control, and flexible heat and UV units support Trusscore’s innovation in smart, functional wall panels. This case illustrates the value of precision lab equipment in developing next-generation building products and pushing the boundaries of material science.

How Can We Help With Your Research?

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.