Solar Cells News | Advances in Thin-Film and Printed PV

Discover the latest news, developments, and applications in slot-die coating technology. From precision coating techniques and equipment updates to real-world use cases in solar cells, batteries, fuel cells, pharmaceuticals, and more, we share the knowledge and progress that drive this versatile and scalable method forward.

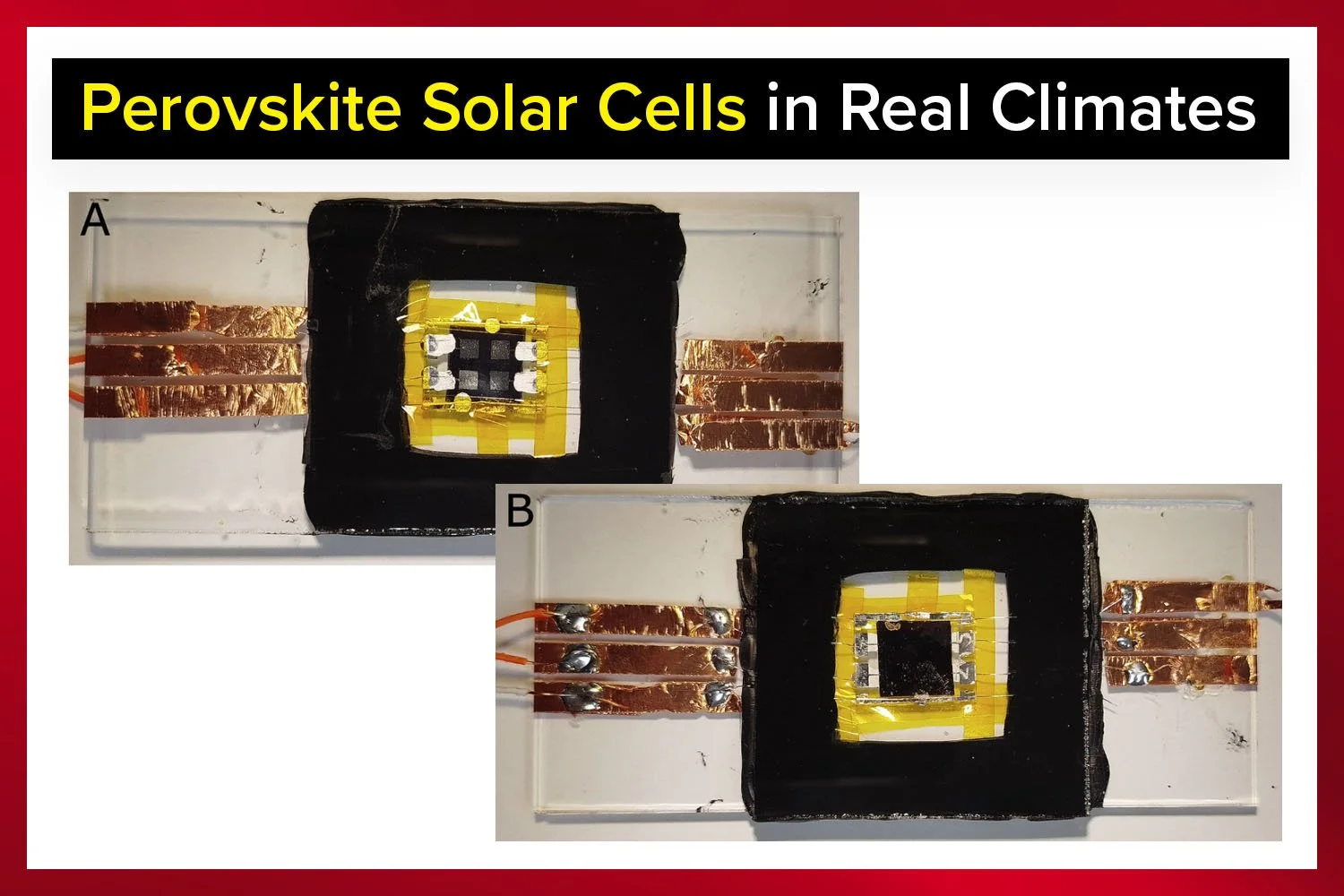

A detailed comparison of accelerated and outdoor aging shows how climate, load and encapsulation influence perovskite solar cell stability.

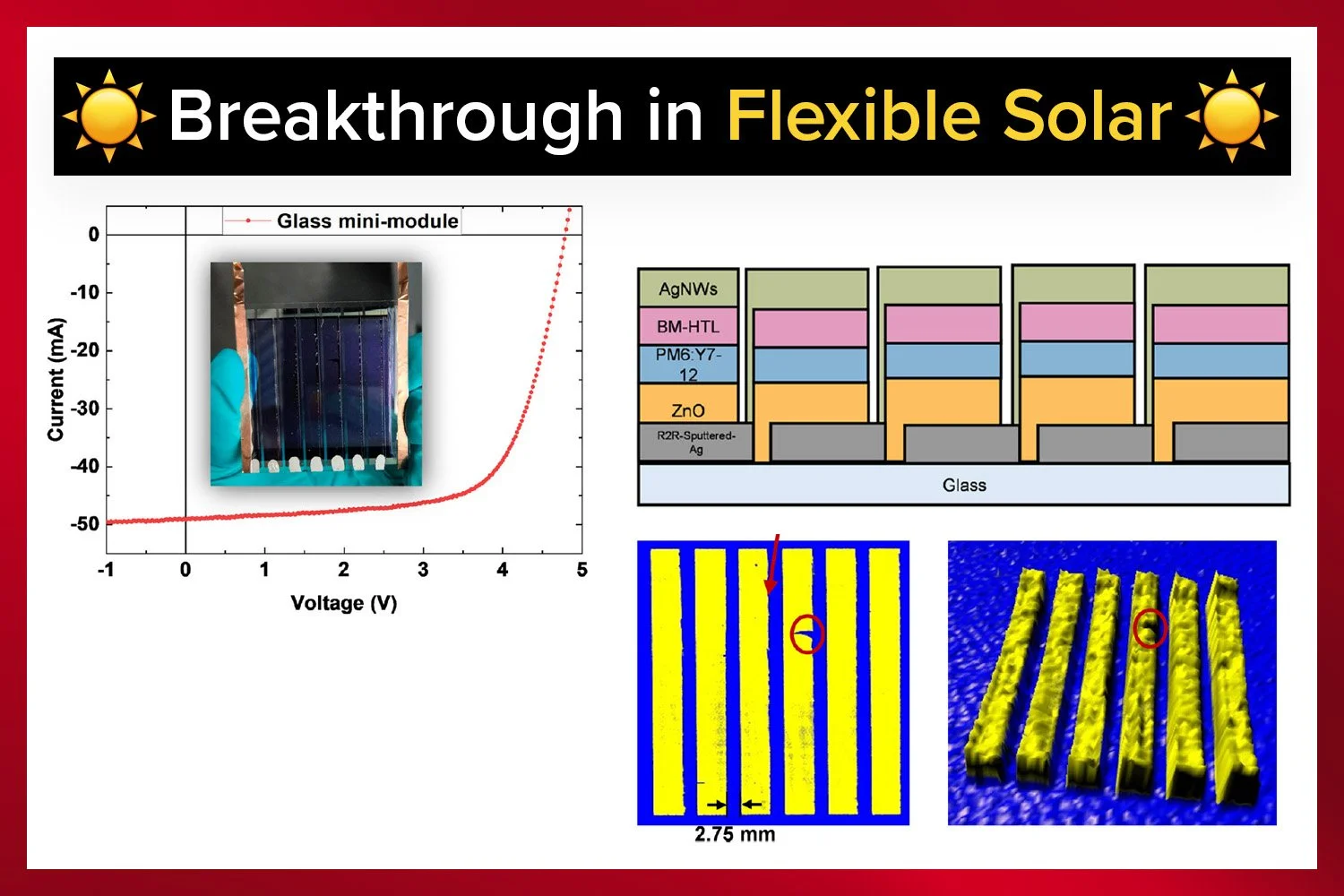

Researchers have developed record-efficient, flexible, ITO-free organic solar modules using a fully roll-to-roll process. The breakthrough shows scalable, sustainable manufacturing for next-generation solar energy.

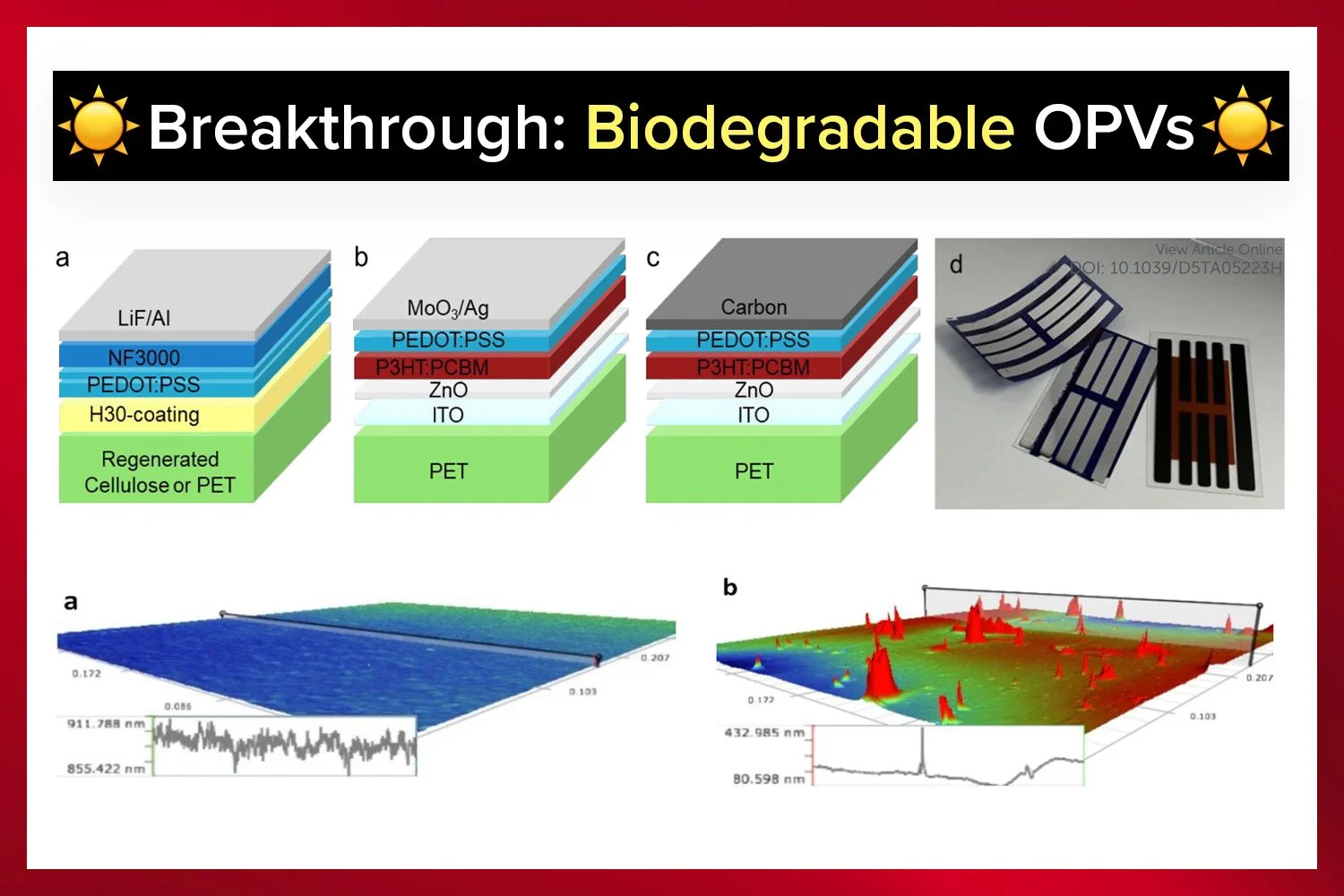

Scientists have built solar cells that can biodegrade naturally after use. Instead of using plastic and metal, they used materials such as cellulose (from plants) and carbon paste, both safe for soil.

Learn why organic and perovskite solar cells, despite record efficiencies, remain slow to commercialize and how collaboration and standardization can bridge the research-to-market gap.

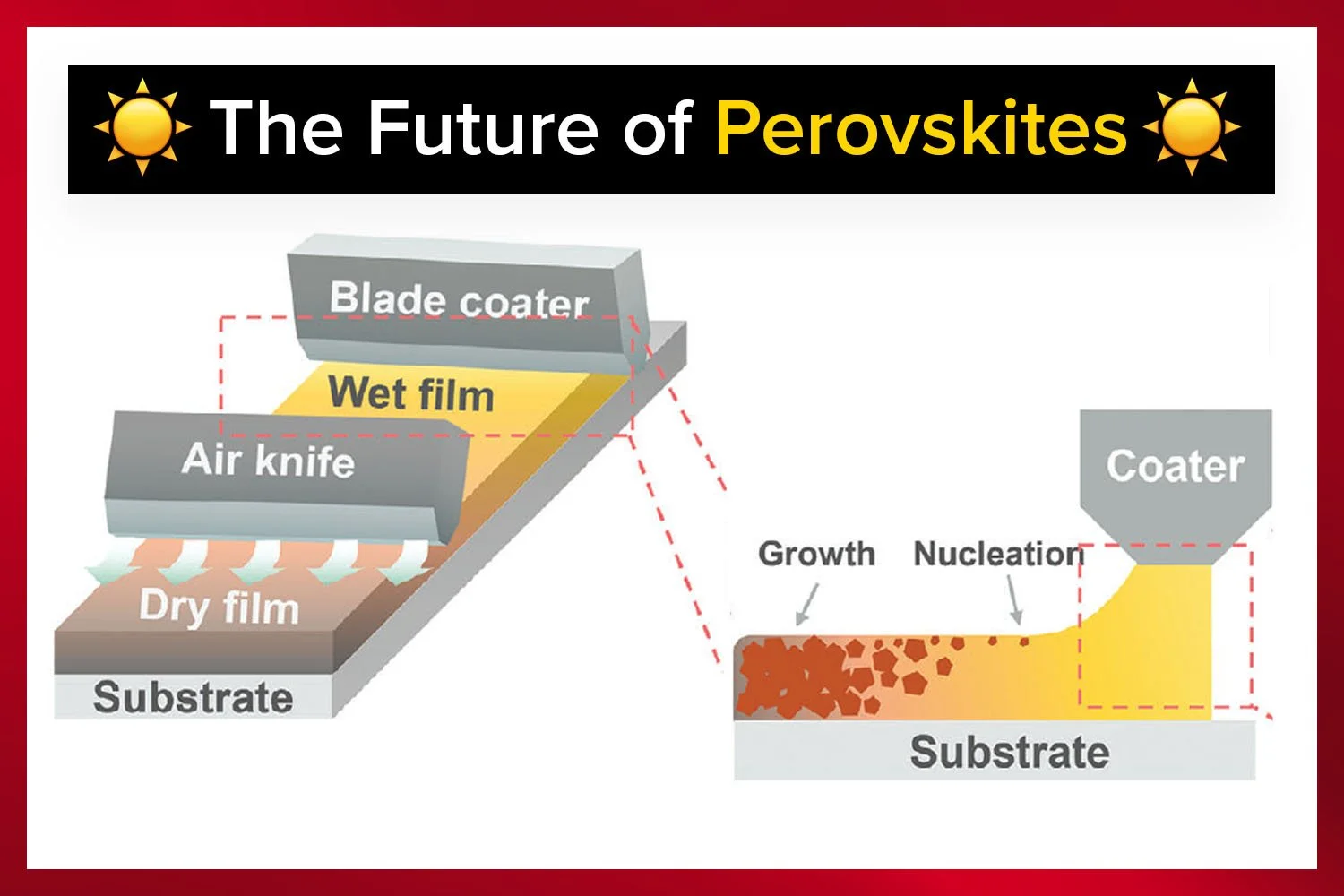

A new study reveals that reshaping colloids in perovskite inks boosts blade-coated solar modules to record efficiencies and stability.

Researchers develop a scalable slot-die process for perovskite solar modules in air, reaching 17% efficiency and record stability.

A new study demonstrates that high-efficiency solar cells and modules can be fabricated using marker pens, offering a low-cost and flexible alternative to traditional solar manufacturing methods.

A new study reveals how device architecture affects the performance and degradation of slot-die coated organic solar cells, showing pathways to scalable, stable, and efficient OPV modules.

A major new review explains how slot-die coating could revolutionize the commercial production of organic and perovskite solar cells, improving scalability, efficiency, and sustainability.

Discover how researchers are using fungi-derived pigments like Xylindein and slot-die coating to develop sustainable, biodegradable organic solar cells.

A new comb nozzle drying technique from KIT enables uniform and large-area perovskite solar films, pushing efficiency up to 24.6 percent and bringing industrial-scale production closer than ever.

A new operando X-ray study reveals how the choice of hole-transport layer impacts thermal degradation in perovskite solar cells. SAM-based HTLs outperform NiOx under heat.

Discover how a 0.75 nm-thick alumina layer applied via atomic layer deposition significantly enhances the stability and efficiency of perovskite solar cells

This breakthrough in perovskite solar cell technology improves efficiency through a dual-layer hole transport strategy, enabling scalable roll-to-roll manufacturing.

Researchers present a detailed review of 115 studies on slot-die-based perovskite solar cells, highlighting how this scalable coating technique holds the key to commercializing next-gen solar technology.

A recent study demonstrates that applying an ultrathin atomic layer deposition (ALD) coating to perovskite solar cells dramatically improves their long-term stability. This innovation could help bring perovskite technology closer to widespread adoption.

Scientists have developed a lightweight hydrogel system for passive solar cell cooling, achieving a 23°C temperature reduction and boosting efficiency by 12.3%. Learn more about this innovative approach to solar energy optimization.

A team of researchers has developed a method to improve the efficiency of organic solar cells, achieving over 20% efficiency and better performance even with thicker active layers. This innovation promises to enable scalable, high-performance solar panels.

A new article outlines key achievements and challenges in the industrialization of perovskite solar cells, focusing on efficiency improvements, stability issues, scalability, and sustainability.

A recent study on perovskite-based PeLEDs reveals their potential to revolutionize display technology by combining fingerprint recognition, health monitoring, and energy harvesting into a single, efficient device. These multifunctional displays pave the way for smarter, more interactive technology in various industries, from wearables to consumer electronics.

The LUMINOSITY project is pushing the boundaries of photovoltaic (PV) technology. This ambitious Horizon Europe-funded initiative aims to develop metal halide perovskite solar modules with over 20% efficiency and a lifespan of 20 years.

This study investigates the innovative use of slot-die coating for depositing niobium pentoxide (Nb₂O₅) as an electron transport layer (ETL) in perovskite solar cells, a technique not previously explored in existing literature.

In the world of solar technology, perovskite solar cells (PSCs) have been gaining attention due to their high efficiency and potential to revolutionize the renewable energy landscape. However, a significant challenge has been scaling these high-performing cells from the lab to real-world, large-area applications.

Emerging research in advanced technology brings attention to the intersecting realms of 5G/6G networks, IoT, and AI, highlighting an escalating demand for environmentally conscious nanostructured materials with adaptable characteristics. Researchers have unveiled responsive composite films, meticulously crafted by integrating VO2 nanoparticles into a biopolymeric network of cationic cellulose nanofibers (CNF+).

The global Internet-of-Things (IoT) market is poised for exponential growth, with projections soaring from €444.10 billion in 2022 to €2288.68 billion by 2029. This represents a staggering compound annual growth rate of 26.4% over the forecast period. The applications of IoT devices span across a multitude of sectors, including smart grids, cities, homes, self-driven cars, wearable electronics, and more. However, powering these devices with conventional batteries presents challenges such as heaviness, rigidity, limited lifespan, and the use of toxic and scarce materials.

Exciting News in Solar Cell Research! Researchers have discovered a groundbreaking way to enhance the stability and efficiency of perovskite solar cells using formamidinium lead iodide (FAPbI3). By introducing a trace amount of cadmium (CdI2), they've unlocked a whole new level of performance.

In a recent study, researchers incorporated pseudo-halogen thiocyanate (SCN) ions in iodide/bromide mixed halide perovskites, leading to remarkable enhancements. Mixed halide wide-bandgap perovskites present promising opportunities for tandem photovoltaics such as perovskite/organic solar cells. However, the challenge lies in halide phase segregation, which limits device efficiency and lifespan.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Slot-die Heads for High-Performance Precision Coating

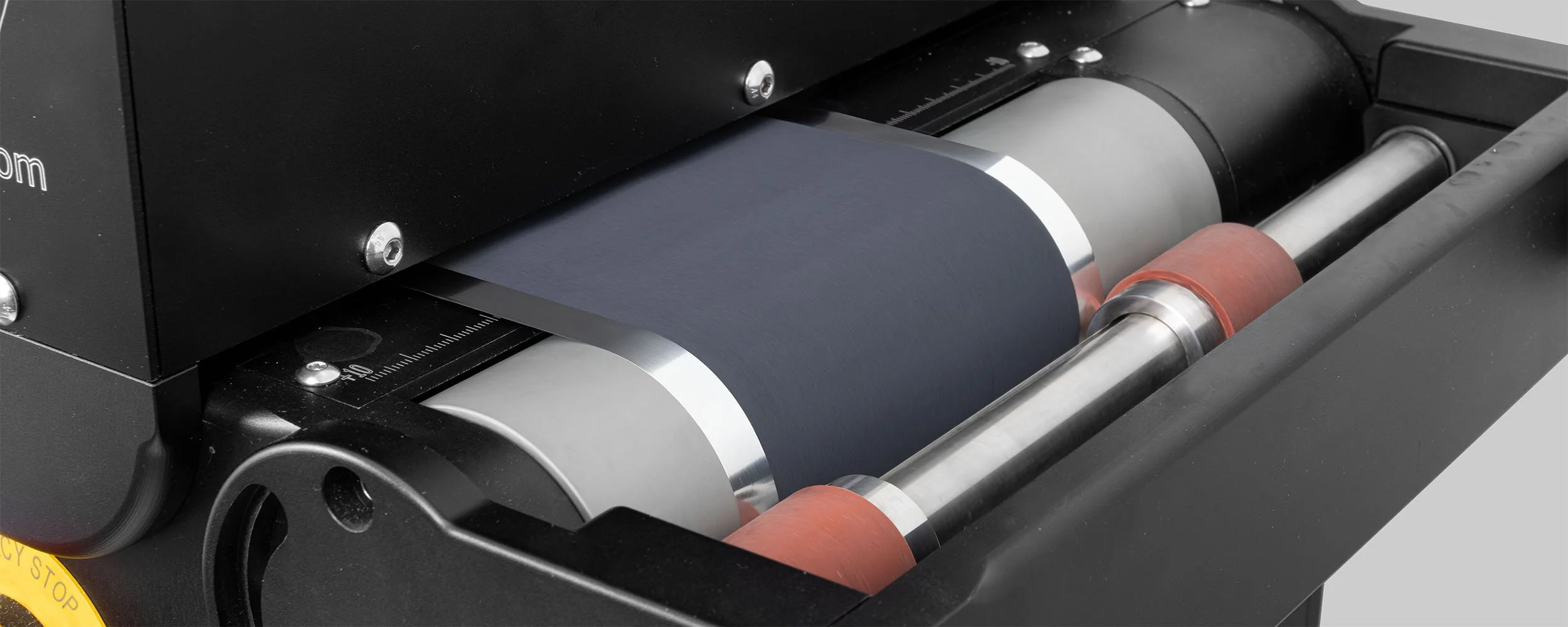

Whether you're working on batteries, pharmaceuticals, solar cells, or other thin-film technologies, this video guides you through the full process of using infinityPV’s slot-die heads—from assembly and mounting to precision adjustment, coating, and cleaning. Available in stainless steel, titanium, and PEEK, and in widths from 40 to 305 mm, these slot-die heads are engineered for accuracy, repeatability, and compatibility with all infinityPV platforms.

We Are Trusted by the World’s Top Scientists

How researchers used the infinityPV LBIC to achieve record-high performance in ITO-free, roll-to-roll processed organic solar modules.

How researchers pushed perovskite efficiency from 19.1% to 20.5% and retained 98% output after 1500 hours of outdoor testing using SMU.

Researchers achieved record efficiencies of 17.6% for flexible perovskite solar cells using the Research Laboratory Coater from infinityPV.