How Roll-to-Roll Coating Accelerates Membrane Development for Fuel Cells and Electrolyzers at Kempten University

Precision Coating for Advanced Drug Delivery

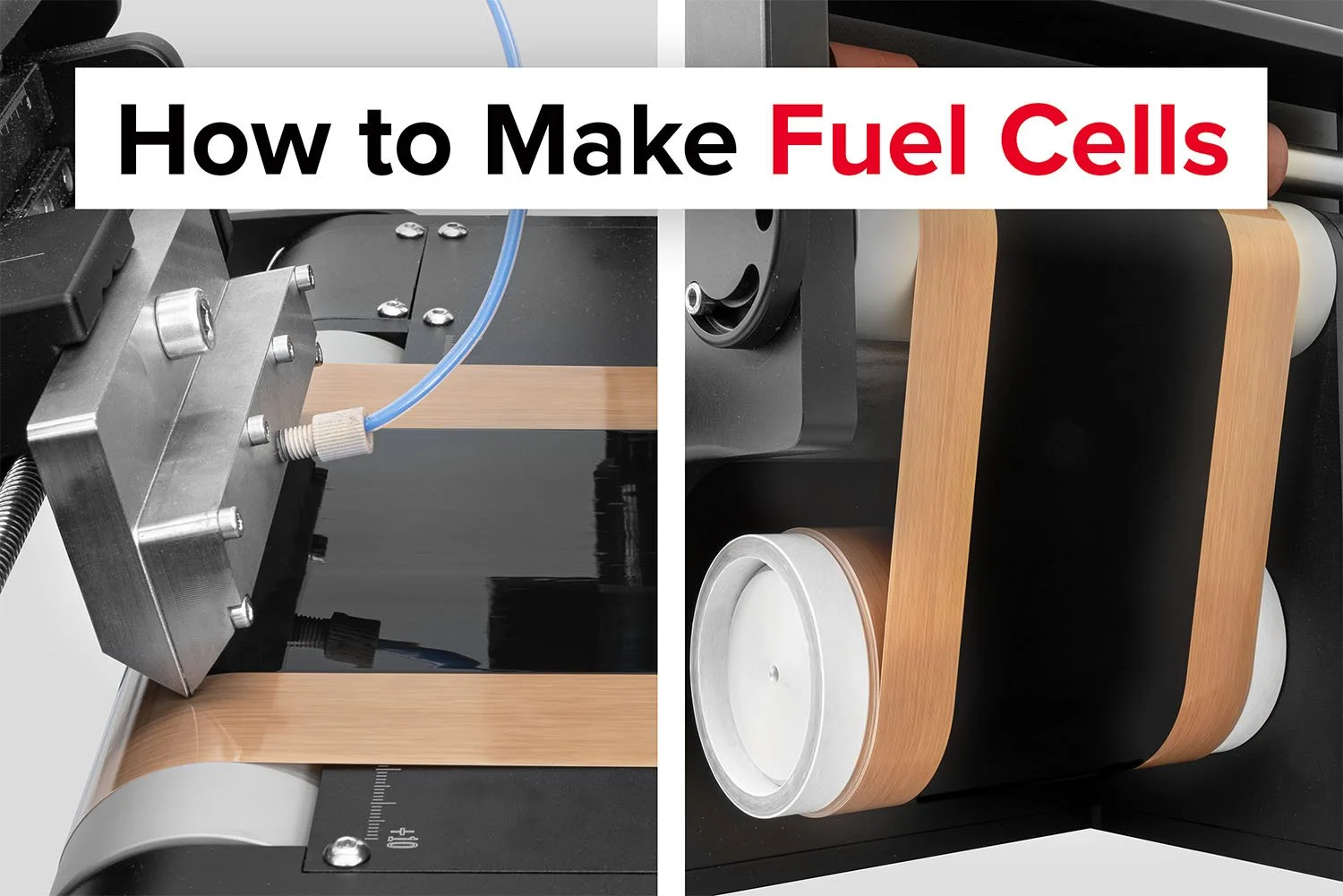

The Laboratory for Hydrogen Technologies at Kempten University of Applied Sciences uses the Laboratory Roll-to-Roll Coater to advance research on fuel cells and electrolyzers. This high-precision coater enables the fabrication of membrane electrode assemblies (MEAs) with consistent quality, which is essential for developing PFAS-free fuel cells and optimizing electrochemical performance.

Current fuel cells rely on PFAS compounds, which are environmentally persistent and pose health risks. Developing PFAS-free alternatives while maintaining performance requires precise and reproducible coating of thin polymer membranes.

The Laboratory Roll-to-Roll Coater allows researchers to coat membranes with electrodes in a controlled, repeatable process. It supports work with PFAS-free materials and integrates seamlessly with quality control systems, including ex-situ roll-to-roll test stands and 2D µ-Röntgenfluorescence spectroscopy for detecting defects.

In the GIRAFFE project, the coater is used to fabricate PFAS-free membranes for safer fuel cell stacks. In DirectStack2Scale, it enables the production of high-quality alternative MEAs for scalable testing. ProtoCell benefits from the coater for research on new MEA architectures and manufacturing methods, while QUALLE uses it to study the impact of defects on MEA performance and fuel cell stack durability.

The coater works alongside the laboratory’s MEA prototyping line, which handles coating, drying, and electrode assembly, and the stack press and hardware used to assemble fuel cell stacks. Together, these systems allow Kempten University researchers to develop PFAS-free fuel cells efficiently and accelerate hydrogen technology innovation.

Learn more here.

How Can We Help With Your Research?

Need help with slot-die coating, coating machines, or any related applications? Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.