Slot-die Coater Enables Real-Time Monitoring and Characterization of Thin Film Drug Delivery Systems

Precision Coating for Next-Generation Pharmaceuticals

At the Technical University of Denmark, a team of researchers set out to advance drug delivery technologies by exploring thin films designed for buccal administration. These films promise faster onset of action and improved dosing accuracy, particularly for patients who struggle with conventional tablets. To succeed, the team needed a way to fabricate dual-layered polymeric films with exceptional reproducibility. Their work relied on the Research Laboratory Coater (since evolved into the Slot-die Coater) from infinityPV, which provided the accuracy and flexibility required to produce consistent test samples for in-depth characterization.

The Challenge: Reproducibility in Thin Film Fabrication

Thin film drug delivery systems are highly sensitive to variations in thickness, layer integrity, and uniformity of the active pharmaceutical ingredient. Even small inconsistencies can compromise drug release profiles and therapeutic effectiveness. Traditional fabrication methods are prone to such inconsistencies, leading to unreliable results and difficulties in studying the films under real-world conditions. The researchers required a reliable method to produce films with controlled structure, free of defects, and adaptable for different formulations.

The Solution: Research Laboratory Coater as a Key Enabler

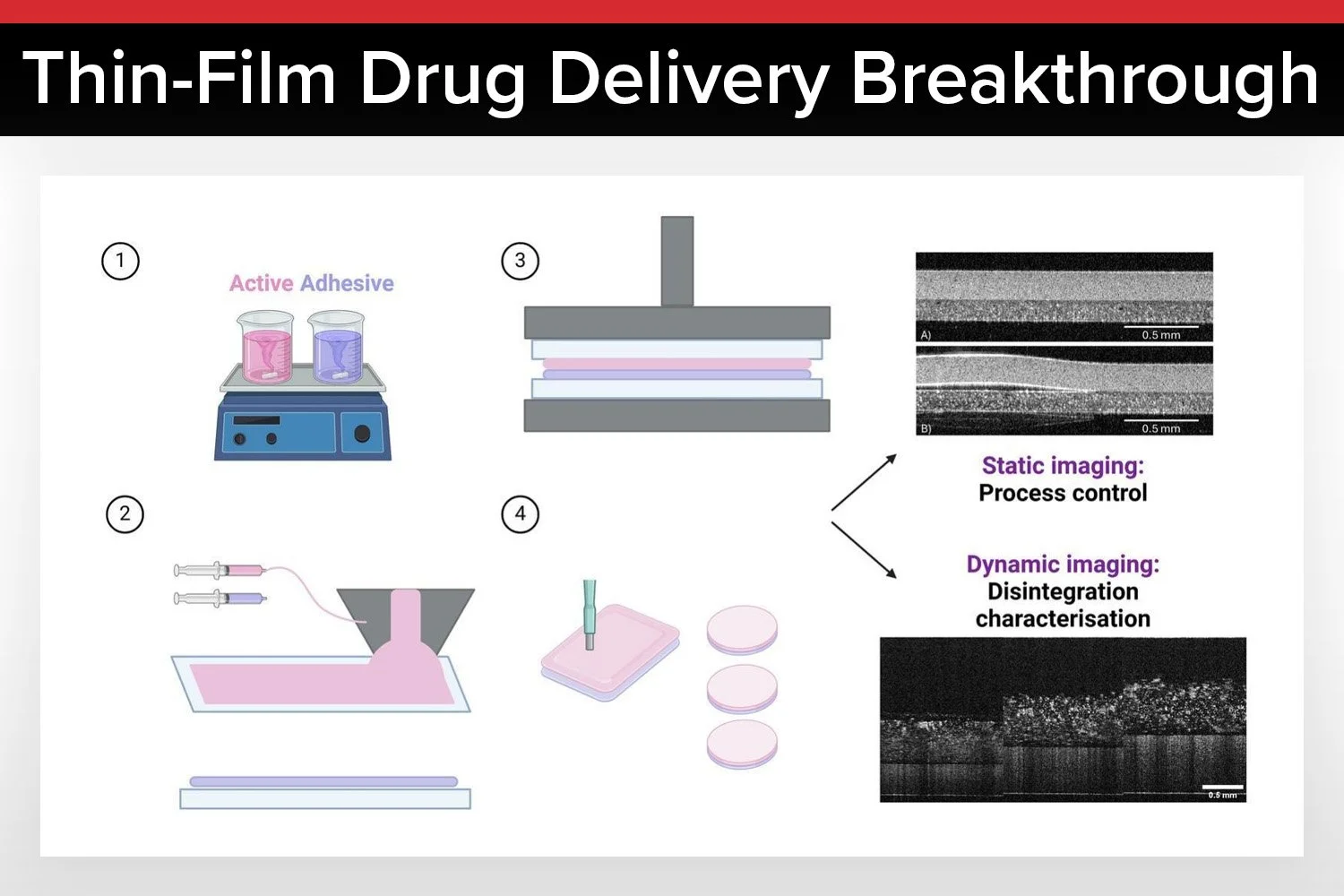

To address this, the team turned to the Research Laboratory Coater. By using a slot-die coating process, they were able to produce dual-layer films with both adhesive and active layers. The system allowed them to fine-tune parameters such as flow rate and coating speed to achieve highly uniform thickness and clear separation between layers. Because of this precision, the films could be fabricated repeatedly with the consistency required for scientific studies. The coater also made it possible to integrate novel formulations and achieve stable films suitable for subsequent characterization with optical coherence tomography (OCT).

The Slot-die Coater was used to produce dual-layer films with both adhesive and active layers.

Results: Reliable Films Driving Breakthrough Research

The quality of the films produced with the Research Laboratory Coater was crucial for the success of the study. The researchers demonstrated that OCT could visualize the internal structure of the films in real time, detect defects such as delamination or air pockets, and measure changes in thickness and refractive index depending on drug concentration. They also observed how the films swelled and disintegrated under simulated physiological conditions, providing new insights into controlled release dynamics. None of this would have been possible without the ability to produce homogeneous, reproducible films, which the coater consistently delivered.

Conclusion: From Laboratory Tool to Pharmaceutical Innovation

This work highlights how the Research Laboratory Coater plays a pivotal role in bridging laboratory research and pharmaceutical development. By enabling precise fabrication of thin films, it allowed scientists to push forward with real-time monitoring of drug release mechanisms and quality control. The study not only validated the potential of optical coherence tomography for drug delivery research but also demonstrated that reliable coating technology is the foundation upon which such innovations are built.

How Can We Help With Your Research?

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

The infinityPV slot-die heads offer unparalleled performance across various materials and size. Available in PEEK, Stainless and Titanium in standard widths of 40 mm, 65 mm, 115 mm, 165 mm, 195 mm and 305 mm. View video.