LBIC Enables High-Performance Roll-to-Roll Solar Production: Real-World Mapping of ITO-Free OPVs

Precision Mapping for Flexible Solar Innovation

In a recent peer-reviewed study published in Advanced Energy Materials, researchers at the University of Southern Denmark (SDU) showcased how the infinityPV Laser Beam Induced Current (LBIC) system played a crucial role in developing high-performance, ITO-free organic solar modules. By integrating the LBIC platform into their testing workflow, the team could rapidly map current uniformity and detect microscopic defects across flexible, roll-to-roll manufactured solar devices — work that marks a major step toward scalable, sustainable solar technology.

Their modules achieved power conversion efficiencies of up to 11.5 percent on flexible PET substrates, among the highest reported for ITO-free, roll-to-roll processed organic photovoltaics. The LBIC system provided the detailed insights that made this optimization possible, bridging the gap between laboratory-scale fabrication and industrial-scale performance validation.

From Lab Promise to Manufacturing Challenge

Organic photovoltaics are lightweight, flexible, and increasingly efficient, but scaling production introduces complexity. As the SDU team transitioned from small test cells to larger mini-modules, they faced a new set of challenges: ensuring electrical uniformity across interconnected cells, spotting invisible coating defects, and minimizing losses from mechanical scribing. Traditional testing methods couldn’t provide the resolution or speed needed to identify performance variations over large, flexible areas.

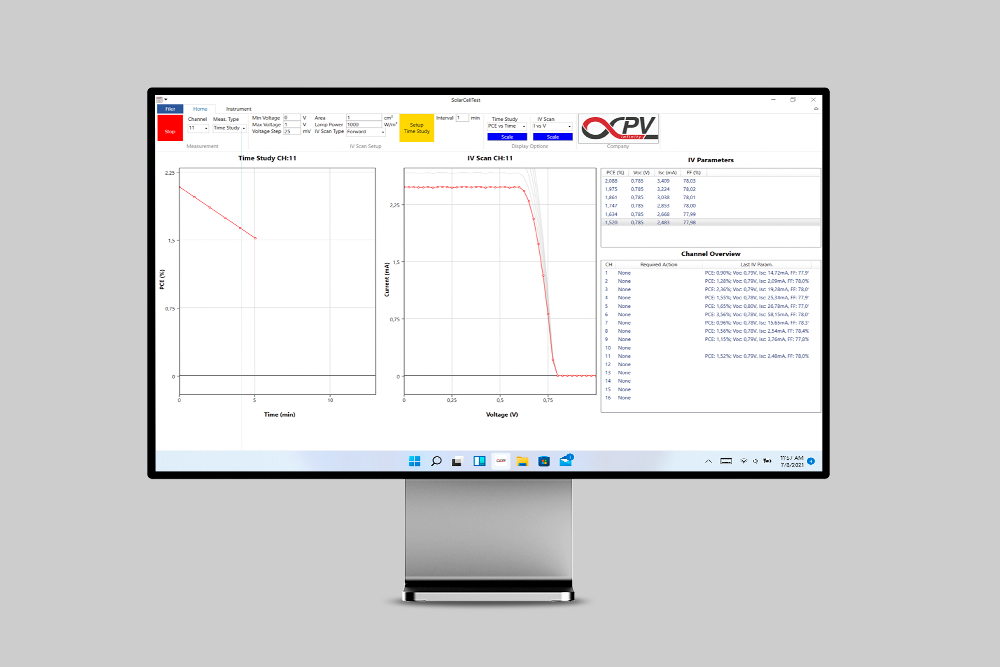

The LBIC operates by shining a small, focused light beam onto the surface of a solar cell and measuring the resulting current or voltage generated at each point.

High-Resolution Insight with LBIC Mapping

To overcome this, the researchers turned to infinityPV’s LBIC platform — a desktop system designed for ultrafast, high-resolution photovoltaic response mapping. Using a 40-micron laser spot and scanning an area of 250 by 250 millimeters, the system generated detailed two- and three-dimensional photocurrent maps in seconds. These maps revealed subtle issues such as uneven scribing lines and small inactive spots while confirming excellent overall uniformity across six-cell mini-modules.

The LBIC data provided direct visual confirmation that the roll-to-roll sputtering and slot-die coating processes were performing as intended. It also offered quantitative evidence of where manufacturing refinements could improve the geometrical fill factor and boost overall device performance.

Proven Performance and Repeatability

Thanks to this precise feedback, SDU’s researchers achieved 12.5 percent efficiency on glass substrates and 11.5 percent on flexible PET, both with remarkable uniformity across multiple modules. Even at a much larger scale — over 100 square centimeters — the modules maintained nearly 10 percent efficiency, setting a new benchmark for ITO-free flexible solar technology.

The LBIC system made it possible to validate these results quickly and non-destructively, offering a level of process insight that would have been difficult to achieve through electrical testing alone.

Mapping the Path to Scalable Solar Manufacturing

By combining roll-to-roll fabrication with advanced LBIC characterization, the SDU team demonstrated a complete, industry-ready route for producing high-efficiency organic solar modules. InfinityPV’s LBIC system was instrumental in confirming quality, detecting defects, and guiding process improvements — turning an experimental concept into a manufacturable, flexible energy solution.

This study highlights how precision mapping technology empowers researchers and manufacturers alike to build the next generation of reliable, scalable solar products.

How Can We Help With Your Research?

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.