Customize Your Laboratory Roll-to-Roll Coater

Select a Platform. Choose Your Components. Get a Quotation.

Not sure which setup works best for you? Choose from our pre-configured machines, or contact our experts to get a custom-built solution tailored to your project.

1. Platforms

The platform size dictates drying length and the number of components supported. Learn more here.

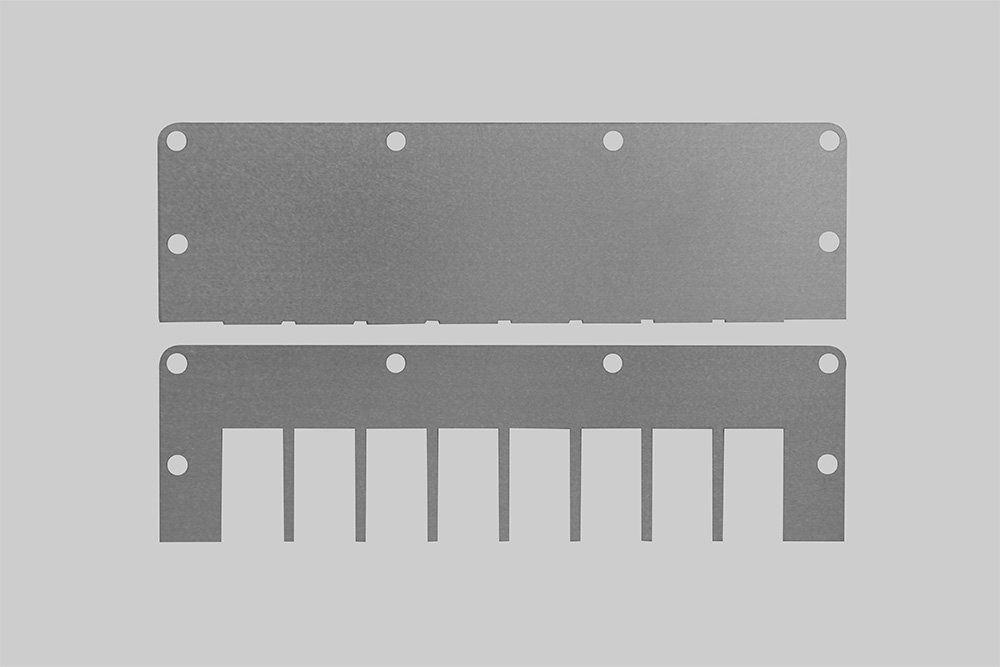

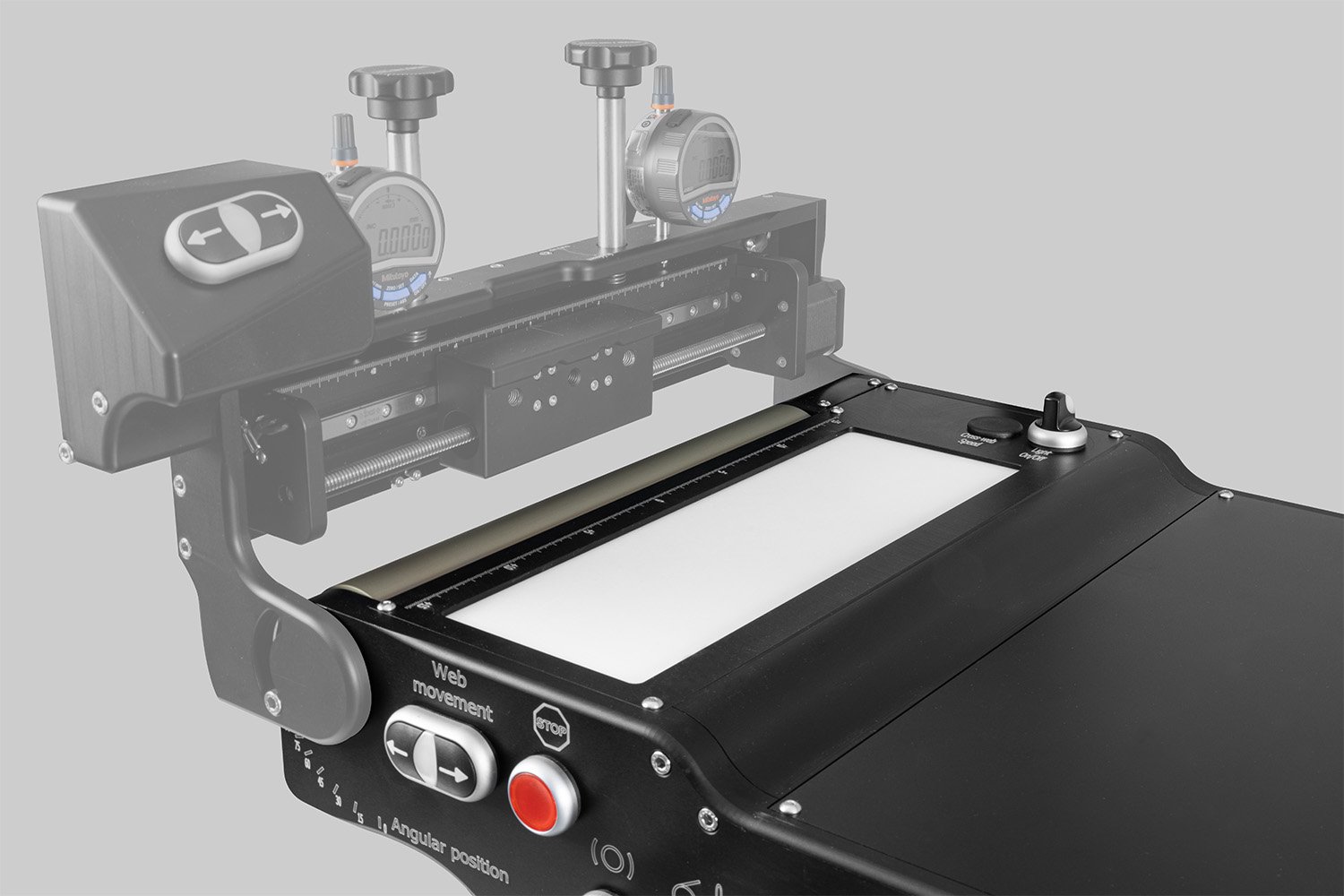

2. Mounts

Precise 0–90° adjustment for coating and printing with manual, digital, or motorized control options. Learn more here.

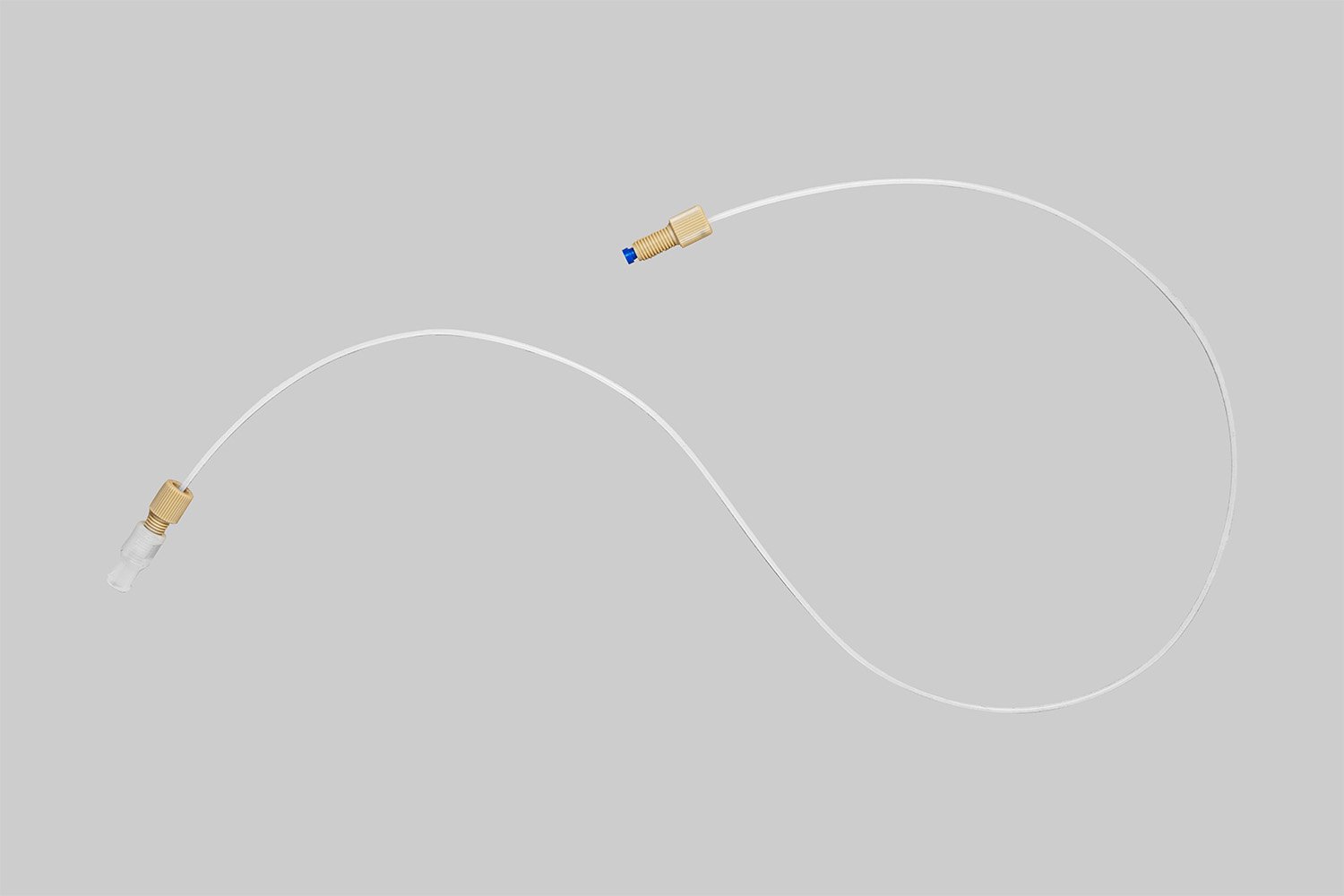

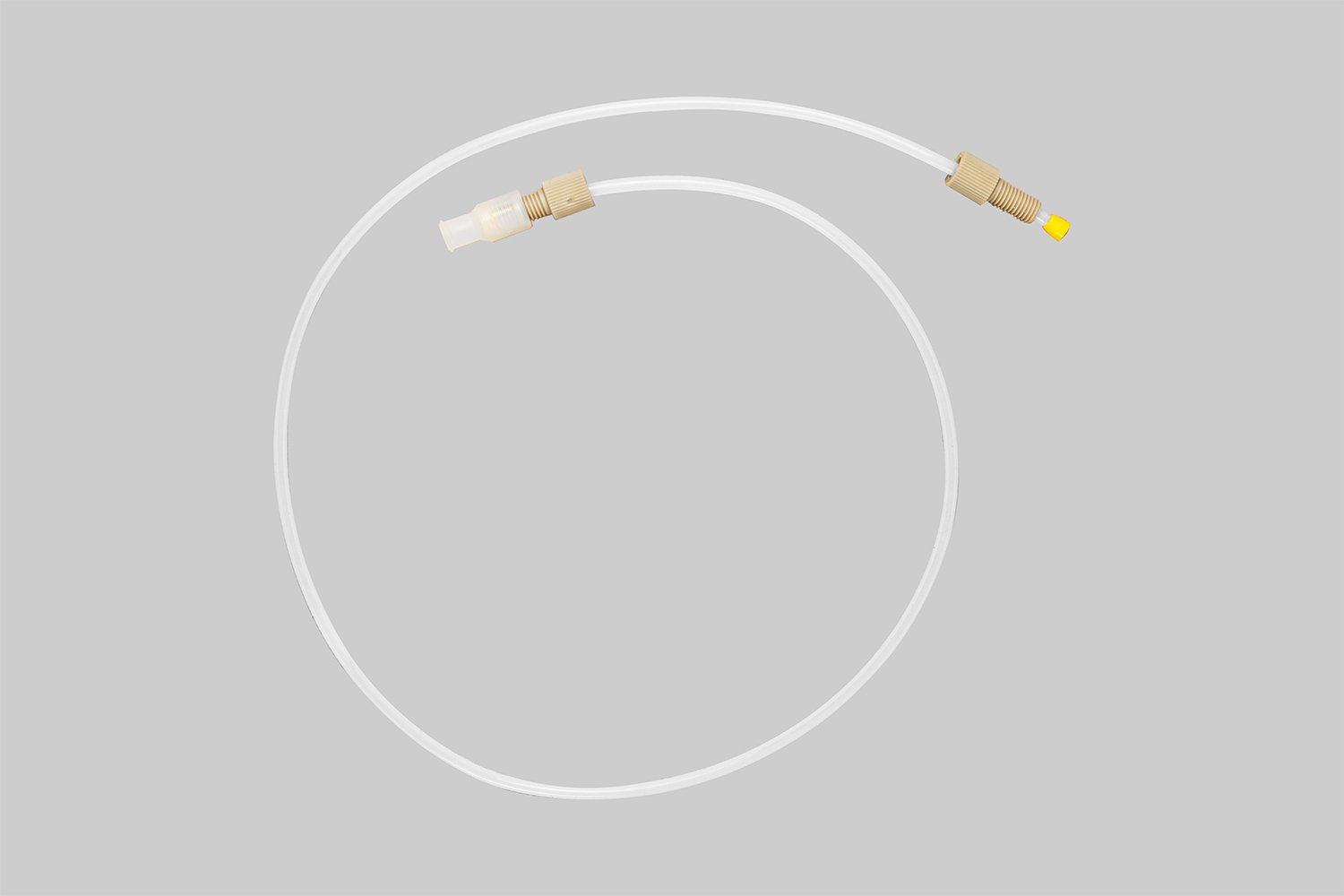

3. Pumps

Syringe pumps for precise dosing and a gear pump for continuous flow. Learn which is right for you here.

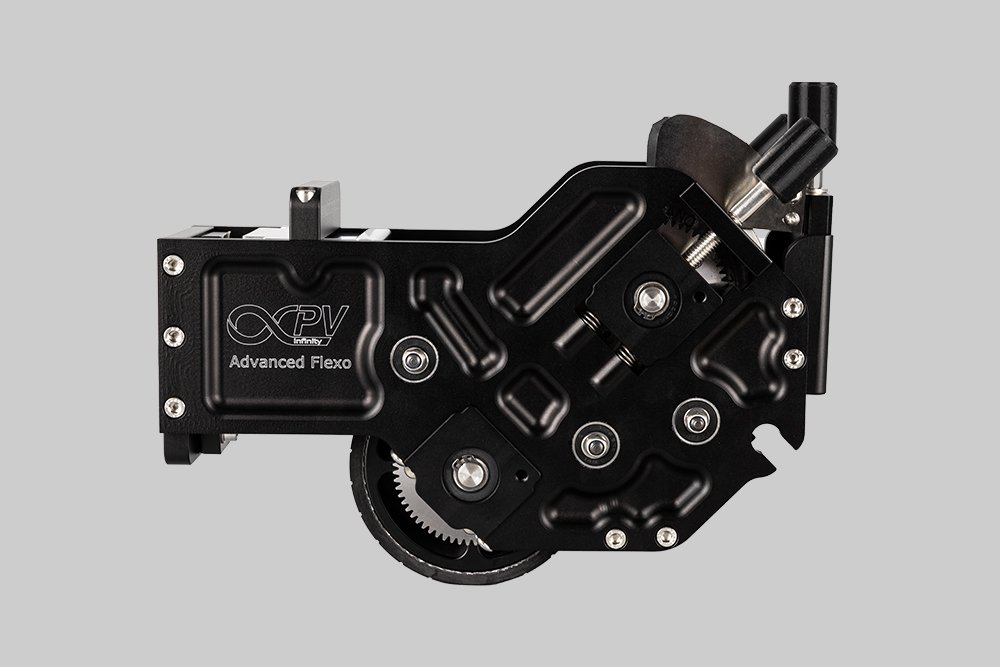

4. Coating and Printing Components

Choose between slot-die heads, slurry coater, flexo rollers and more.

5. Ovens for Drying and Curing

The ovens efficiently dry and cure thin films, with a compact, user-friendly design for quick swaps in under a minute. Learn more here.

6. Web Handling Components

Enhance your coating with lamination, web guiding, surface treatment, and more.

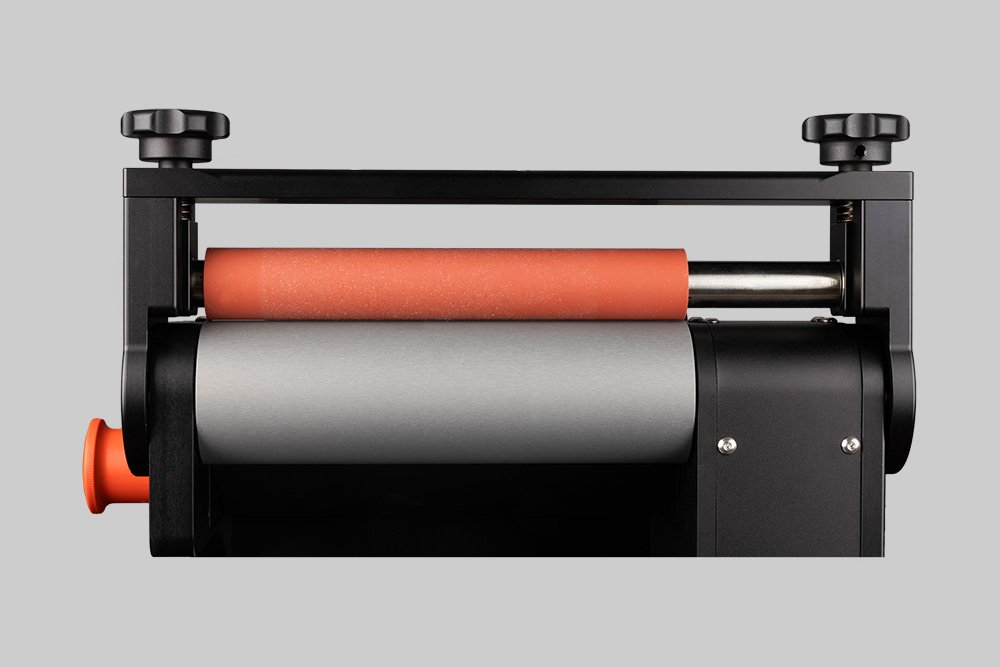

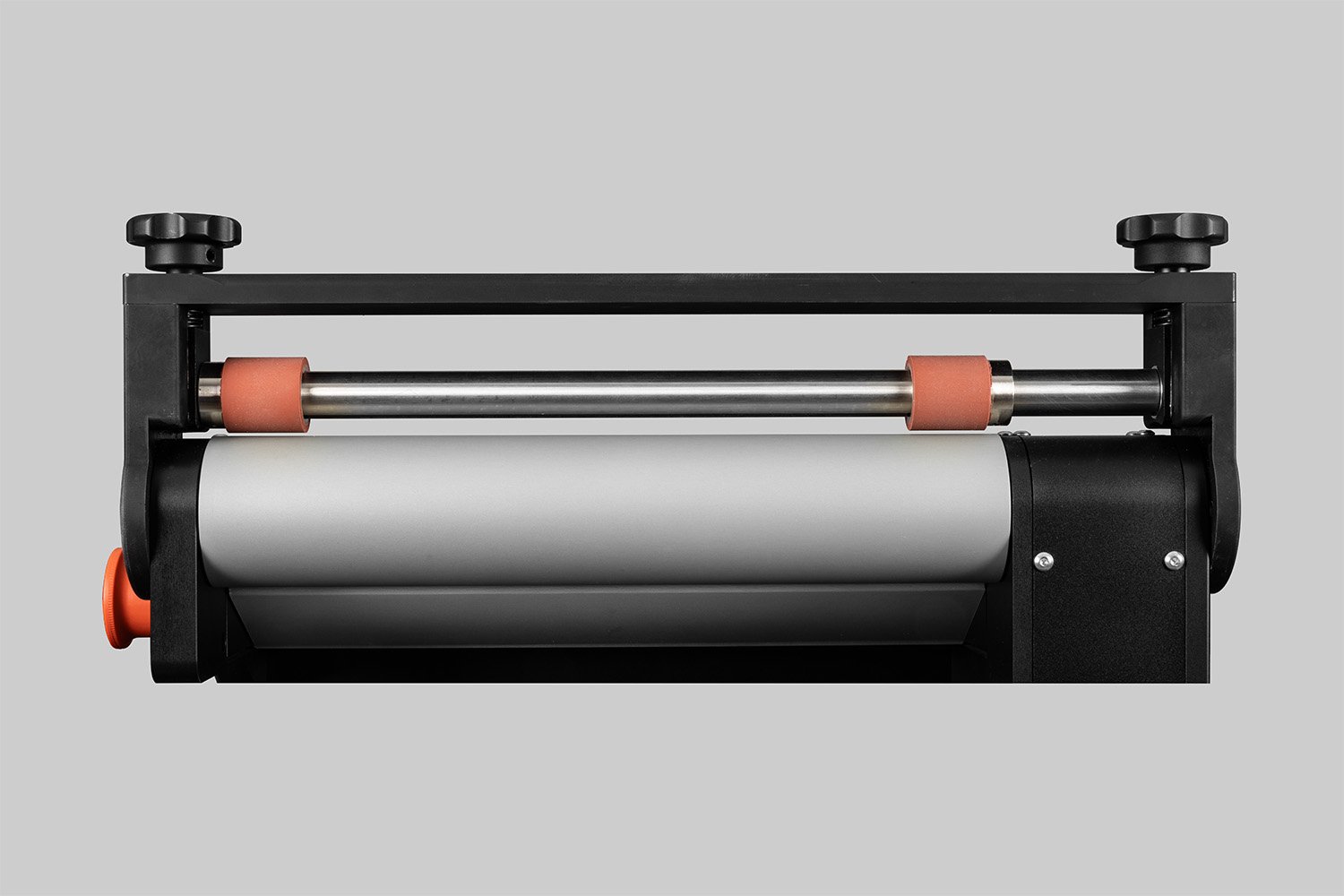

7. Rollers

Upgrade from the included 60 mm anodized aluminum rollers to POM for contrast, PEEK for chemical resistance, and stainless steel for corrosion resistance.

The nip roller enhance web control and speed. Options range from a basic manual rubber roller to advanced adjustable, automated systems.

8. Get a Quotation

You are now ready to receive a quotation. If you are uncertain about your platform or component choices, please contact us. We’d be delighted to assist you.