Precision Heated Slot-die Heads

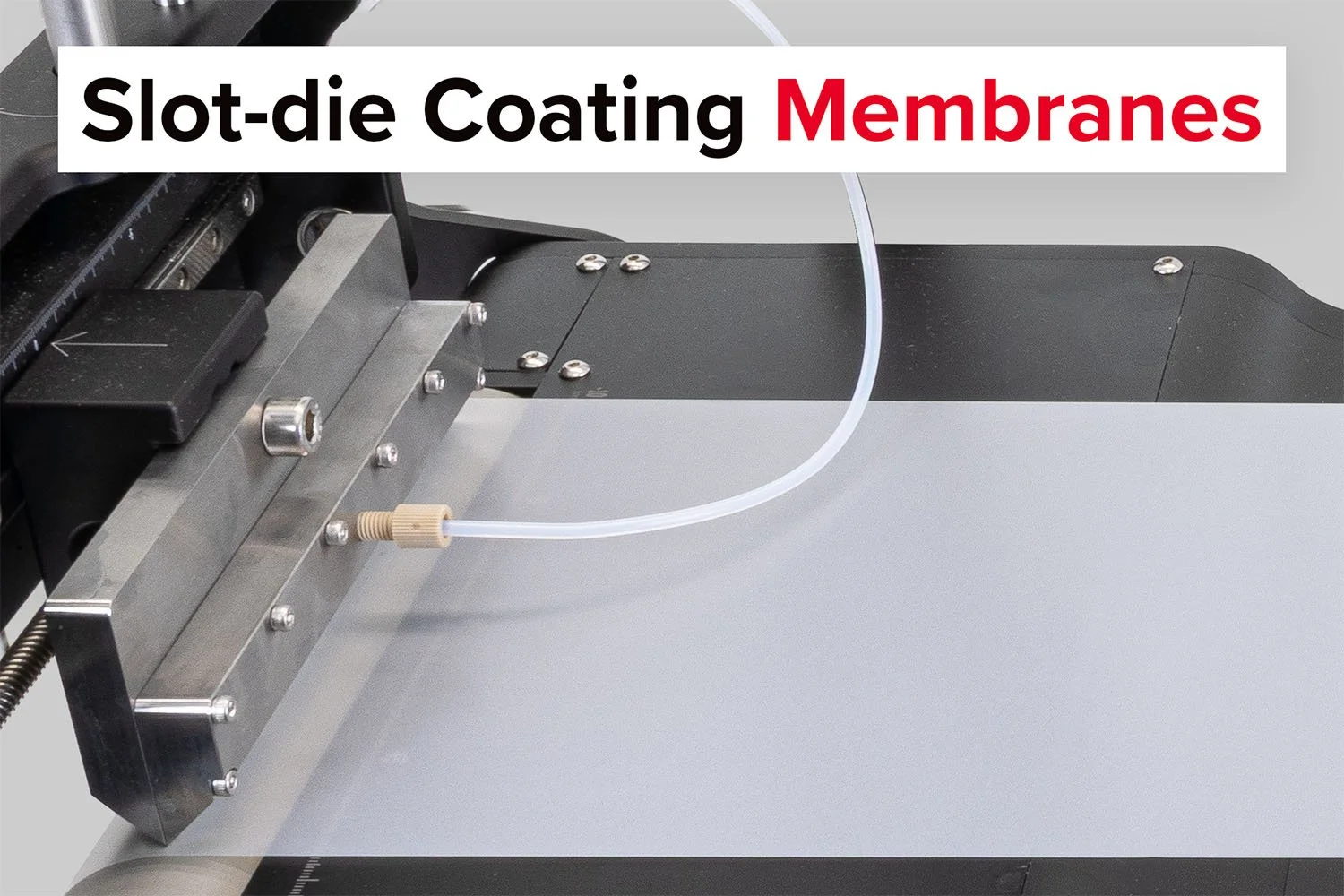

From precision slot-die coating in laboratory settings to seamless industrial-scale production, our heated slot-die heads deliver unmatched performance.

High-Performance Heated Slot-die Heads by infinityPV

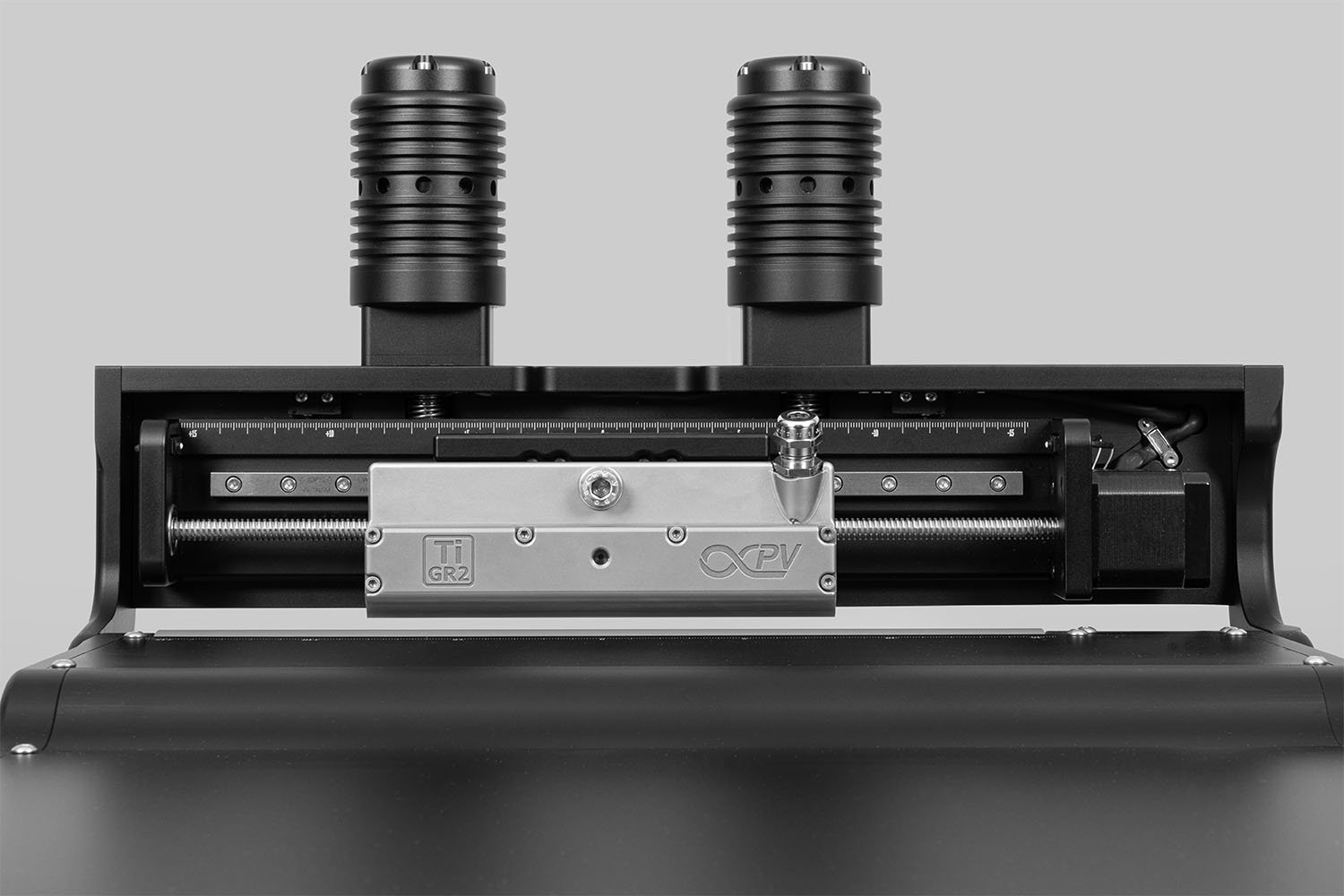

We offer high-precision heated slot-die heads designed for applications that demand accurate coating and stable thermal control. Available in Stainless Steel (316/316L), and Titanium, our heads come in standard widths of 50 mm, 65 mm, 115 mm, and 165 mm. They are built for laboratory, pilot, and industrial-scale use, and feature just two parts for easy cleaning, assembly, and maintenance. Whether working with microliters or milliliters, our heads deliver consistent results across a wide range of materials and flow rates.

For effective heating, we provide both direct and indirect options. While heated mounts are compatible with any head design, they offer limited performance with materials like PEEK, stainless steel, and titanium due to poor thermal conductivity. We recommend heated mounts only for small heads, highly conductive alloys, and low-temperature or low-flow applications. For superior performance, our direct heating options include electrical and liquid-based systems. Electrical heating is the most popular due to its simplicity and reliability, while liquid-based heating provides advanced temperature control for demanding conditions.

All heated slot-die heads can be customized with side or top-slanted entry points for wires or fluid lines. Standard configurations place these on the right side when viewed from the front, but we also offer custom placements to fit your setup. If you are unsure whether a heated head is necessary or which solution suits your needs best, our team is ready to help with expert guidance and personalized support.

Key Features

Standard Available in Widths of:

Accessories

Applications

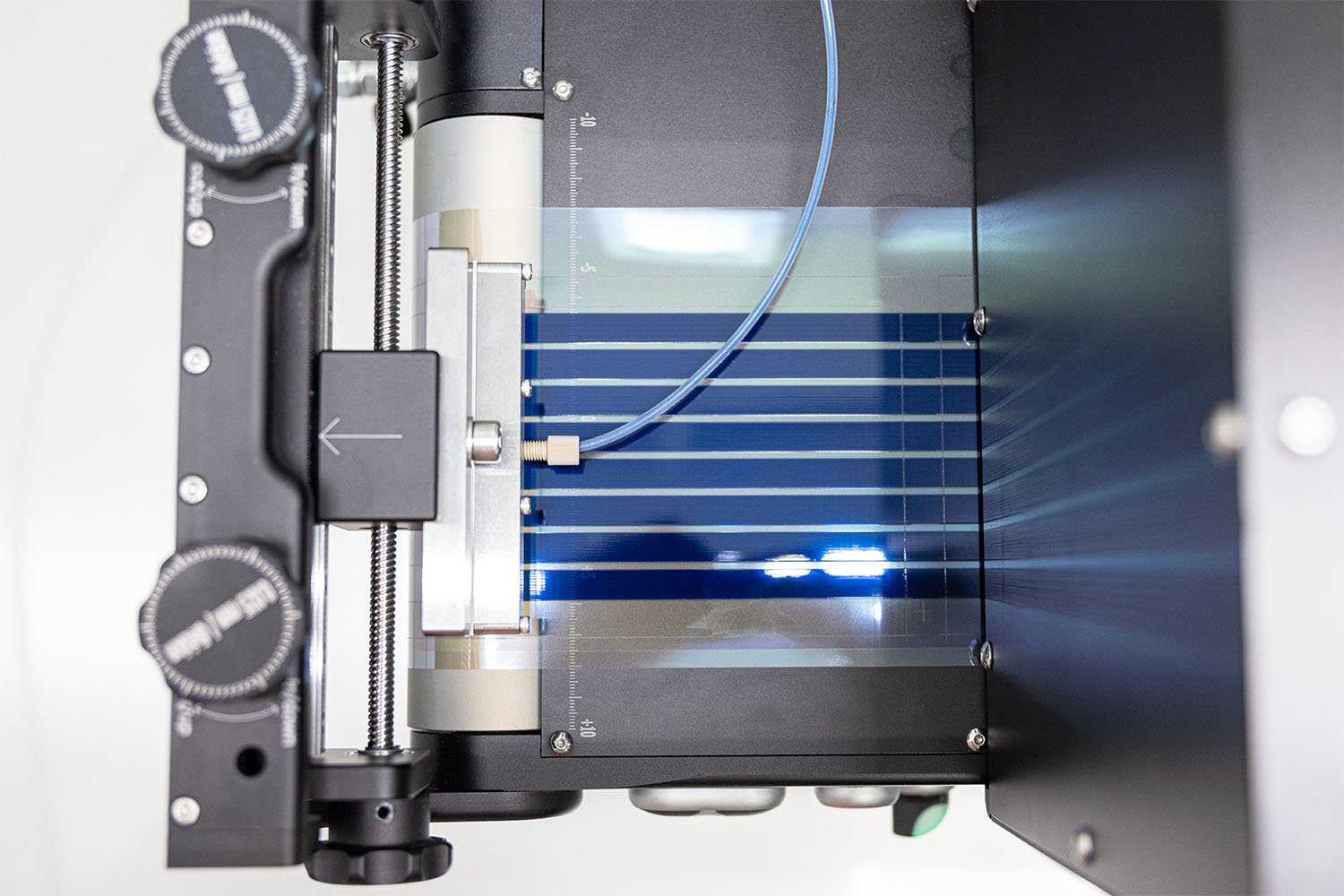

Printed Solar Cells (OPV, Perovskite, DSSC, Tandem)

Adhesives and Sealants

Pharmaceuticals (Biocompatible and Drug-eluting Layers)

Standard, Heated and Customized Slot-die Heads

If you need a customized slot-die head tailored to your specific requirements, our expert team is ready to collaborate with you to design and manufacture a solution that meets your exact needs. View video.

Which Slot-die Head Do YOU Need?

Your coating process is only as good as the head that delivers it. Whether you’re developing batteries, solar cells, fuel cells, pharmaceuticals, or something else, selecting the right slot-die head is critical for quality, efficiency, and cost-effectiveness. In our guide, we break down how to evaluate your needs and help you understand which size and material slot-die head suits your application best.

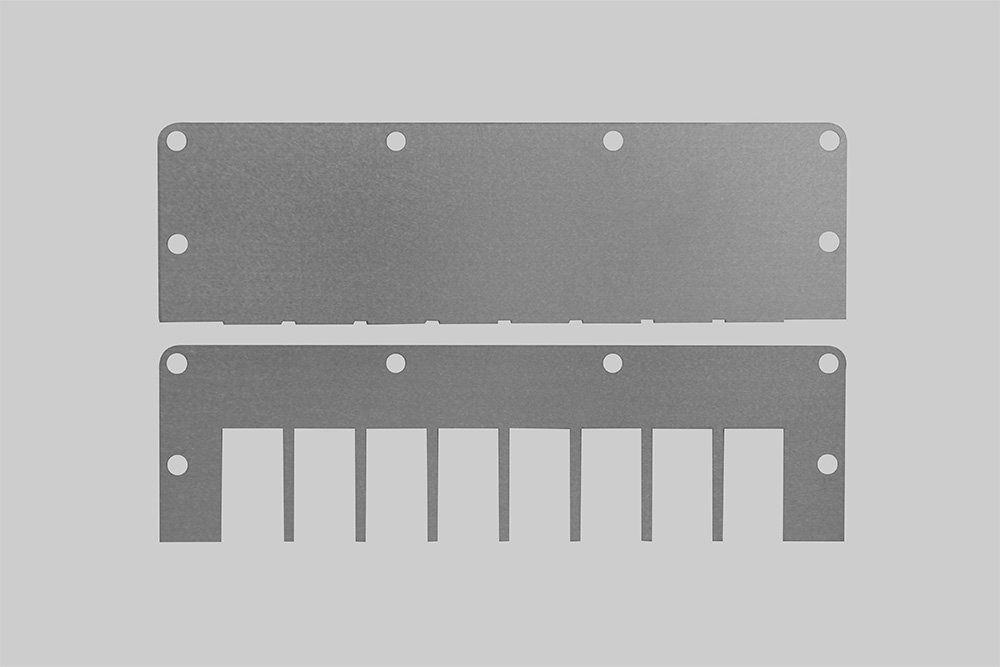

Standard and Customized Shim Kits

We offer both standard and customized shim kits for slot-die heads to meet your precise coating needs. Our standard shim kits provide reliable performance with a variety of thicknesses and materials for general applications, while our customized kits are tailored to fit specific requirements, ensuring optimal coating uniformity and efficiency. Whether you need a standard solution or a bespoke option, our shim kits are engineered to deliver exceptional quality and performance for your slot-die coating system.

Standard Shim Kit

Our standard shim kits are meticulously designed to fit a wide variety of slot-die heads. These kits provide reliable performance and are ideal for many common applications. With a range of thicknesses and materials available, our standard shim kits ensure optimal coating uniformity and efficiency.

Customized Shim Kit

For more specialized needs, we offer customized shim kits tailored to your specific requirements. Whether you need unique dimensions, special materials, or specific thicknesses, our team works closely with you to create a shim kit that perfectly matches your slot-die head and application.

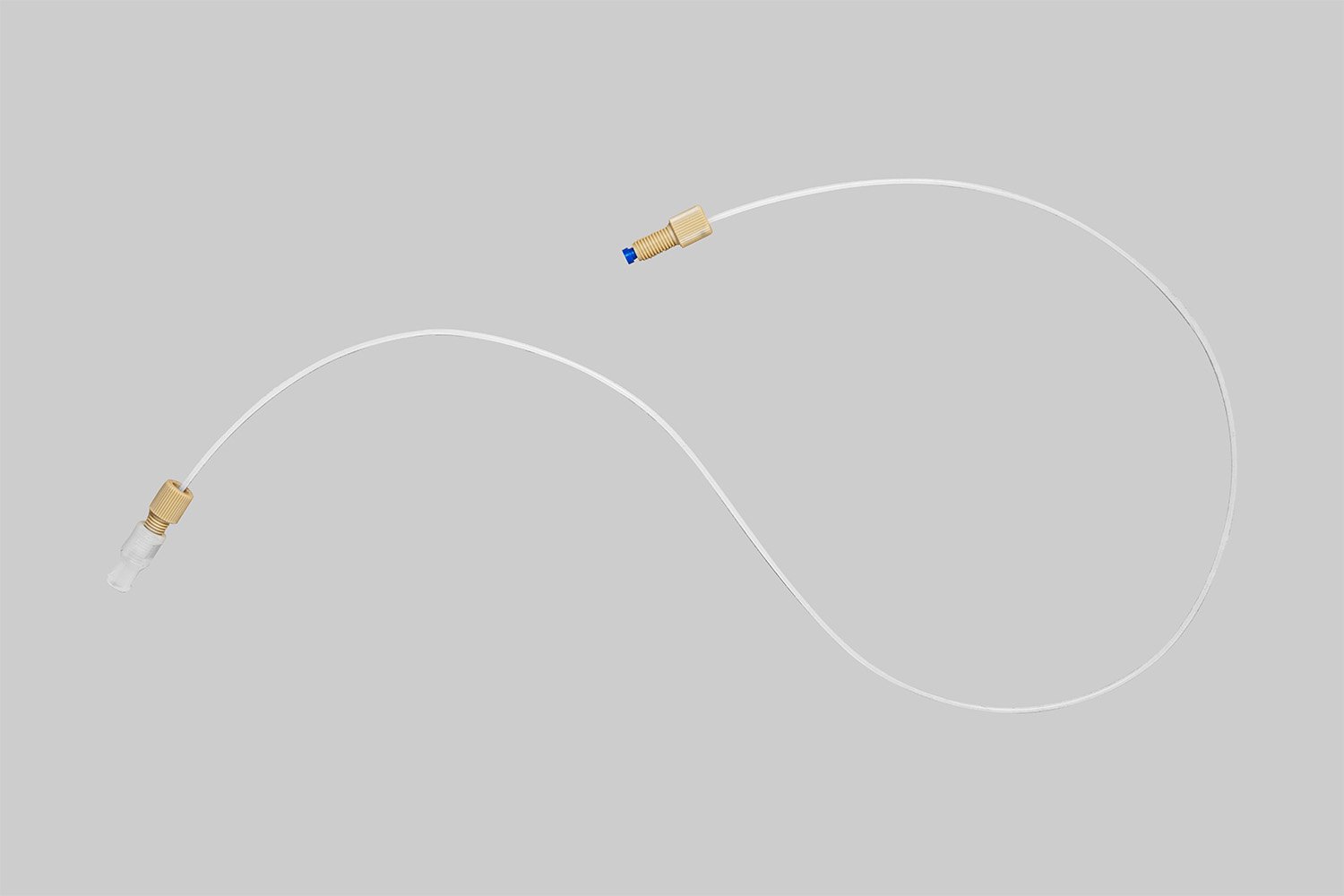

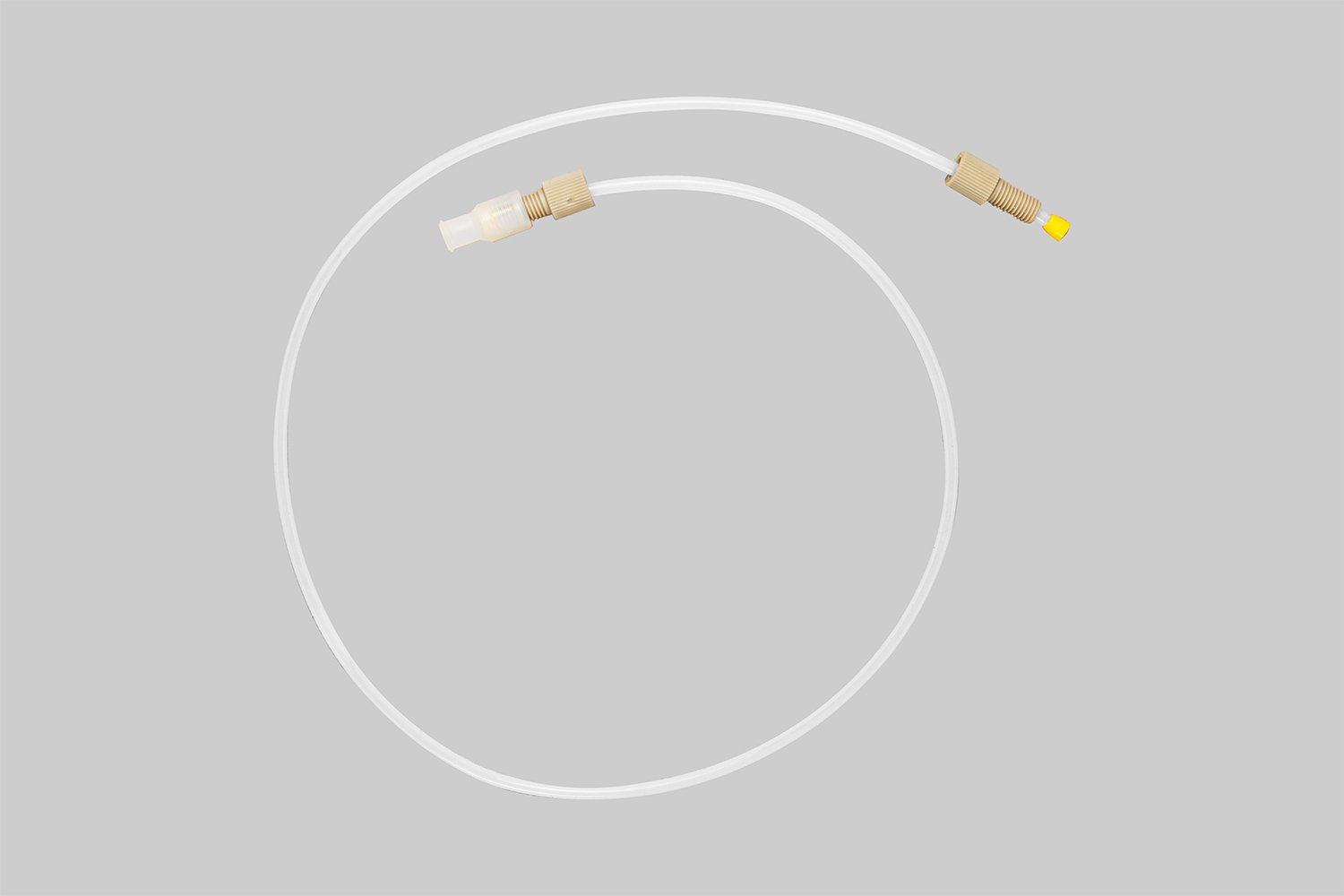

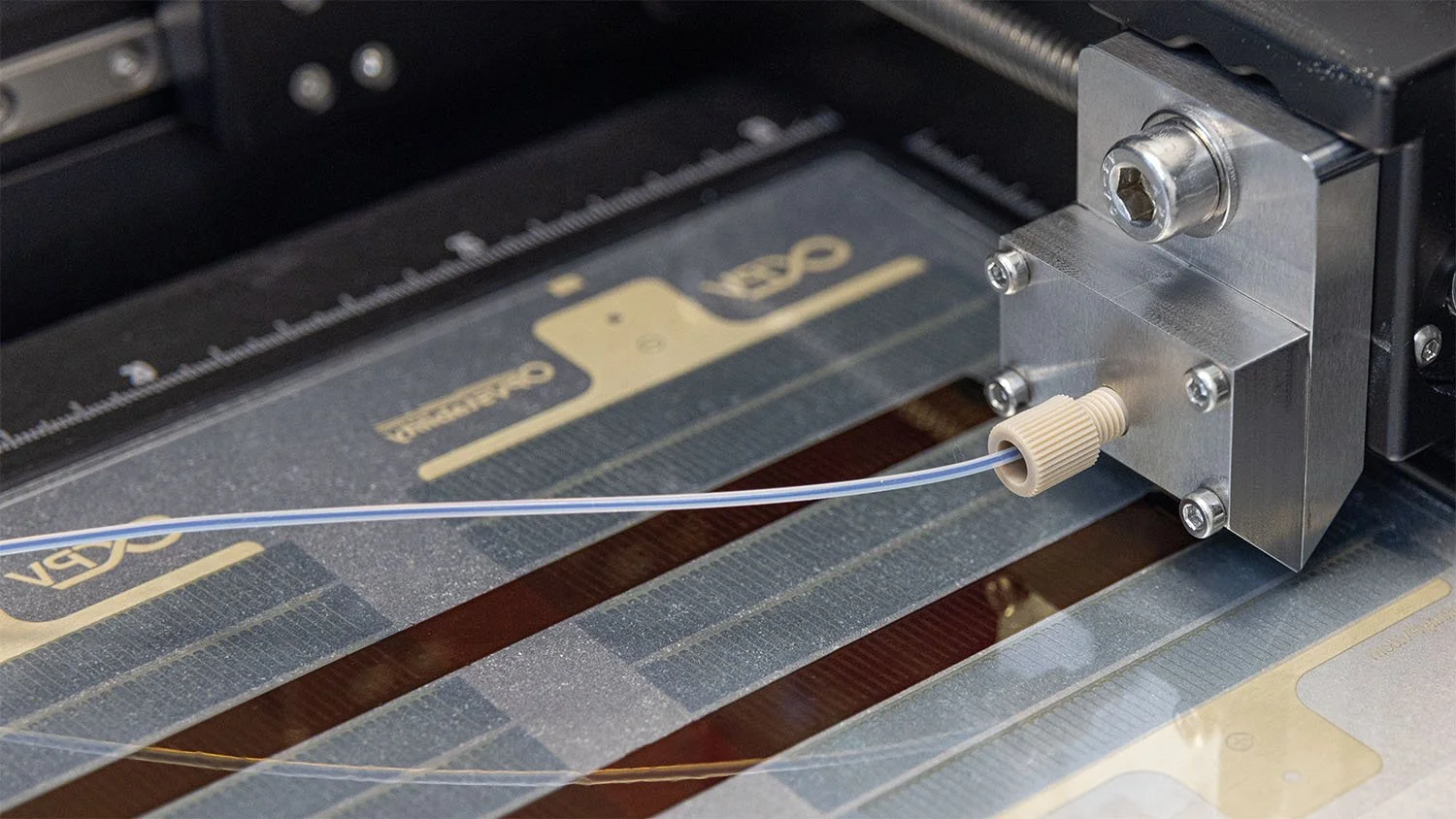

Standard and Customized Fitting Kits

We offer fitting kits for slot-die heads tailored for both low viscosity and high viscosity applications. Our low viscosity fitting kits ensure smooth, consistent flow for thinner coatings, while our high viscosity kits are designed to manage the challenges of thicker materials with precision and reliability. Each kit is engineered to meet the highest standards of quality, enhancing the performance of your slot-die coating system for optimal results.

Low Viscosity Fitting Kit

For applications involving low viscosity coatings, our fitting kits are engineered to deliver smooth, consistent flow and minimal clogging. These kits are designed to enhance the efficiency of your slot-die head, ensuring uniform coating even with thinner materials.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

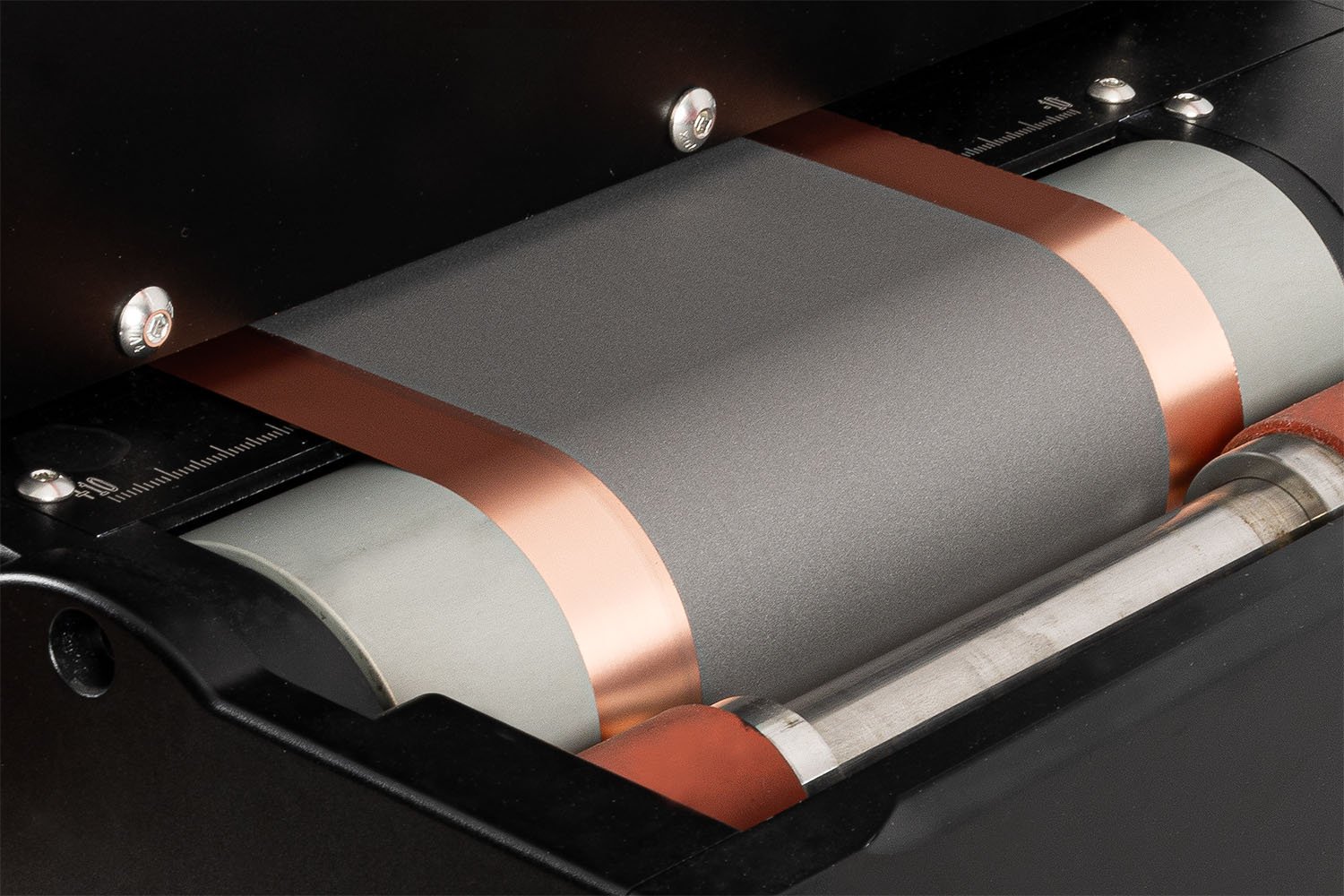

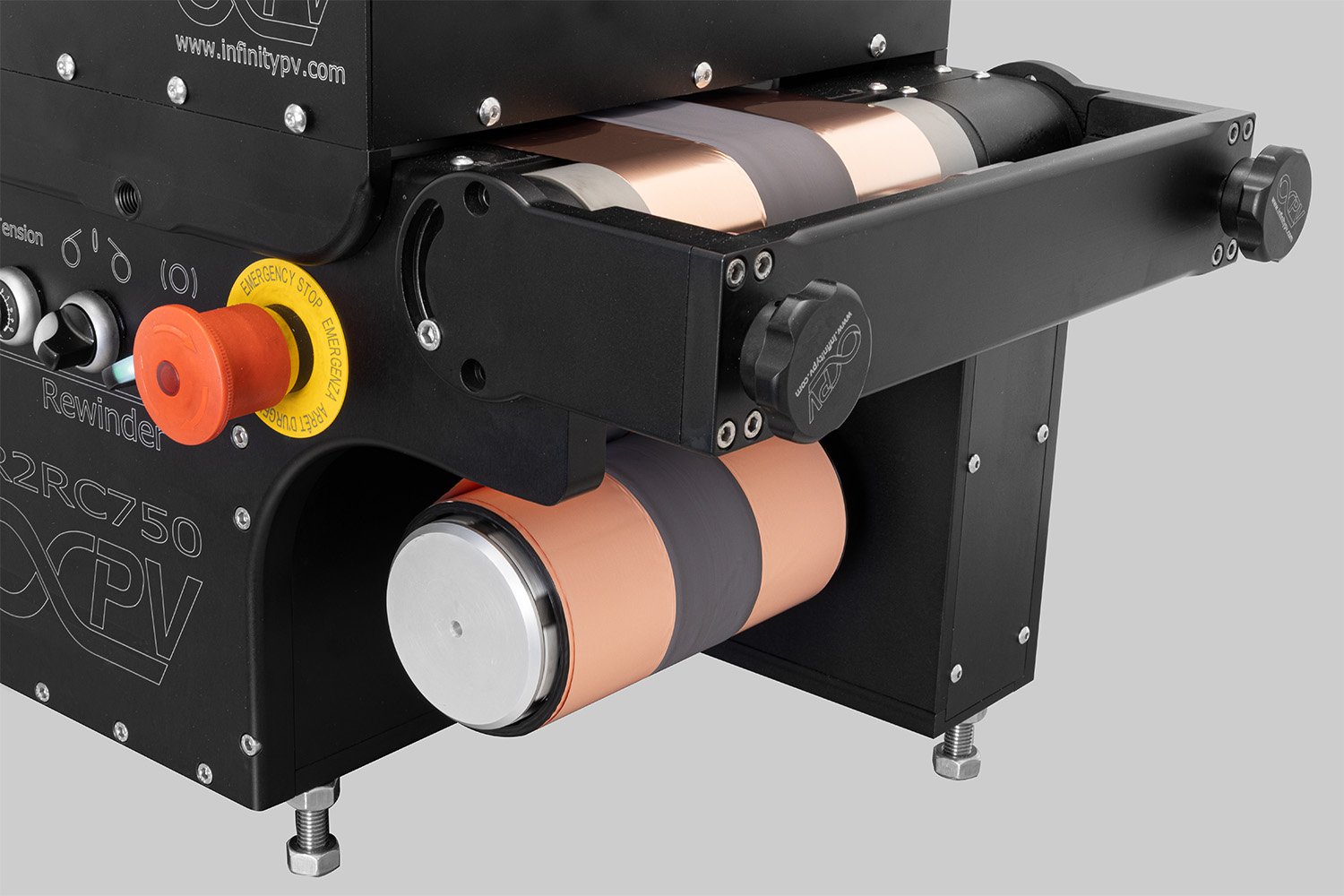

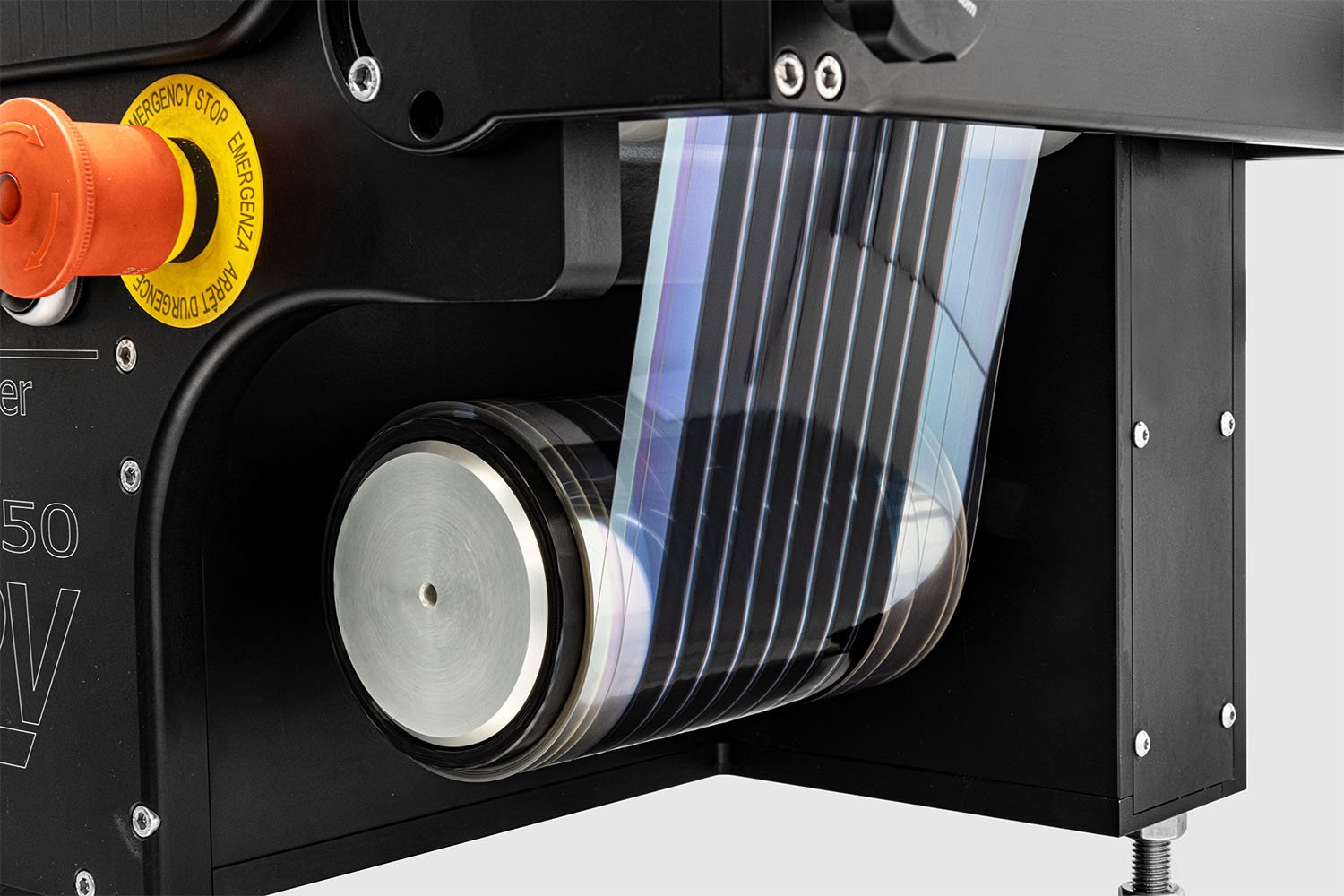

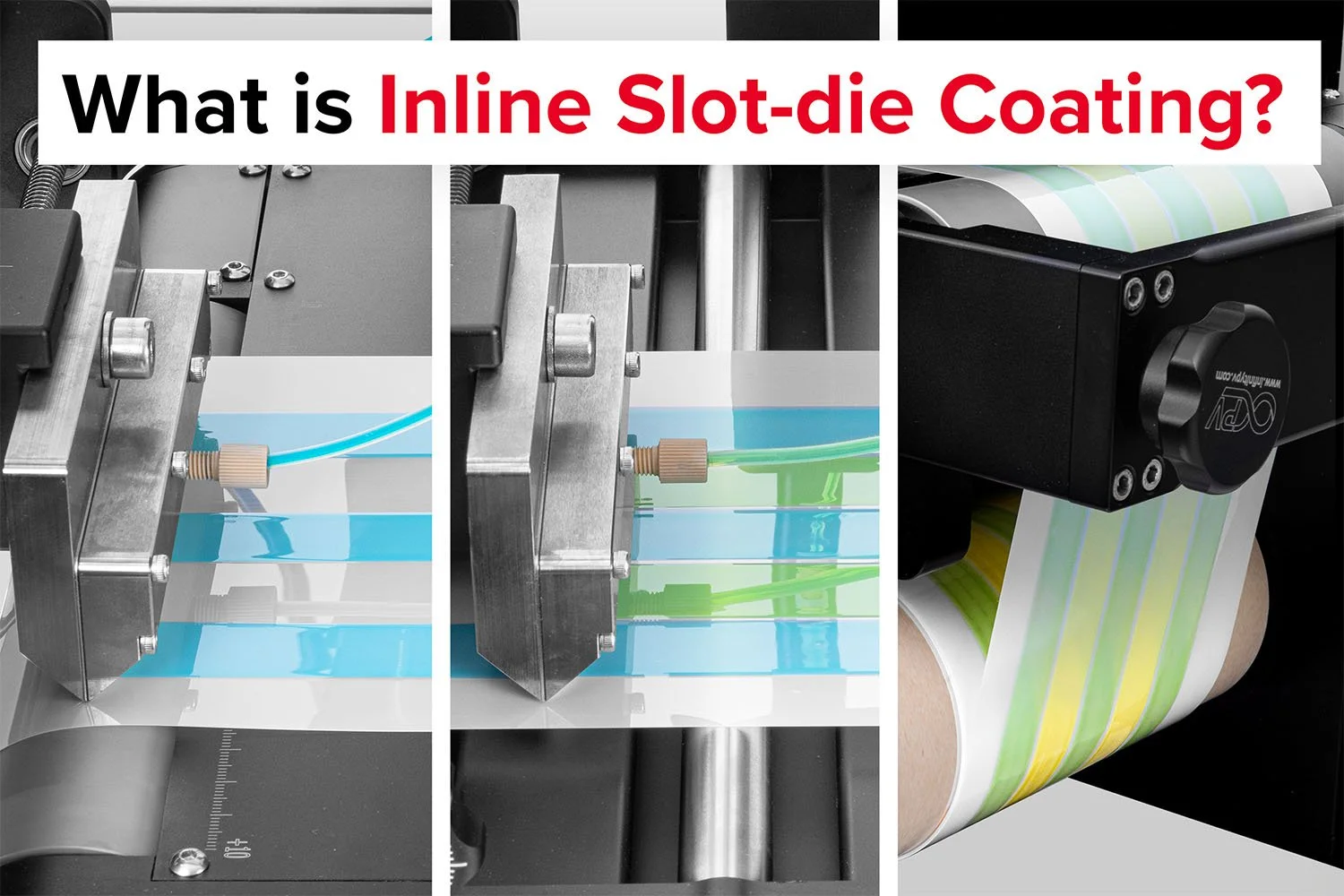

Roll-to-Roll Slot-die Coating

A compact, high-precision lab coater revolutionizing thin film processing. It features modular customization, scalable efficiency for small-scale production, and a user-friendly design. This versatile system caters to various needs, from laboratory to small pilot-scale production, processing hundreds of meters of foil efficiently.

Videos About Slot-die Coating

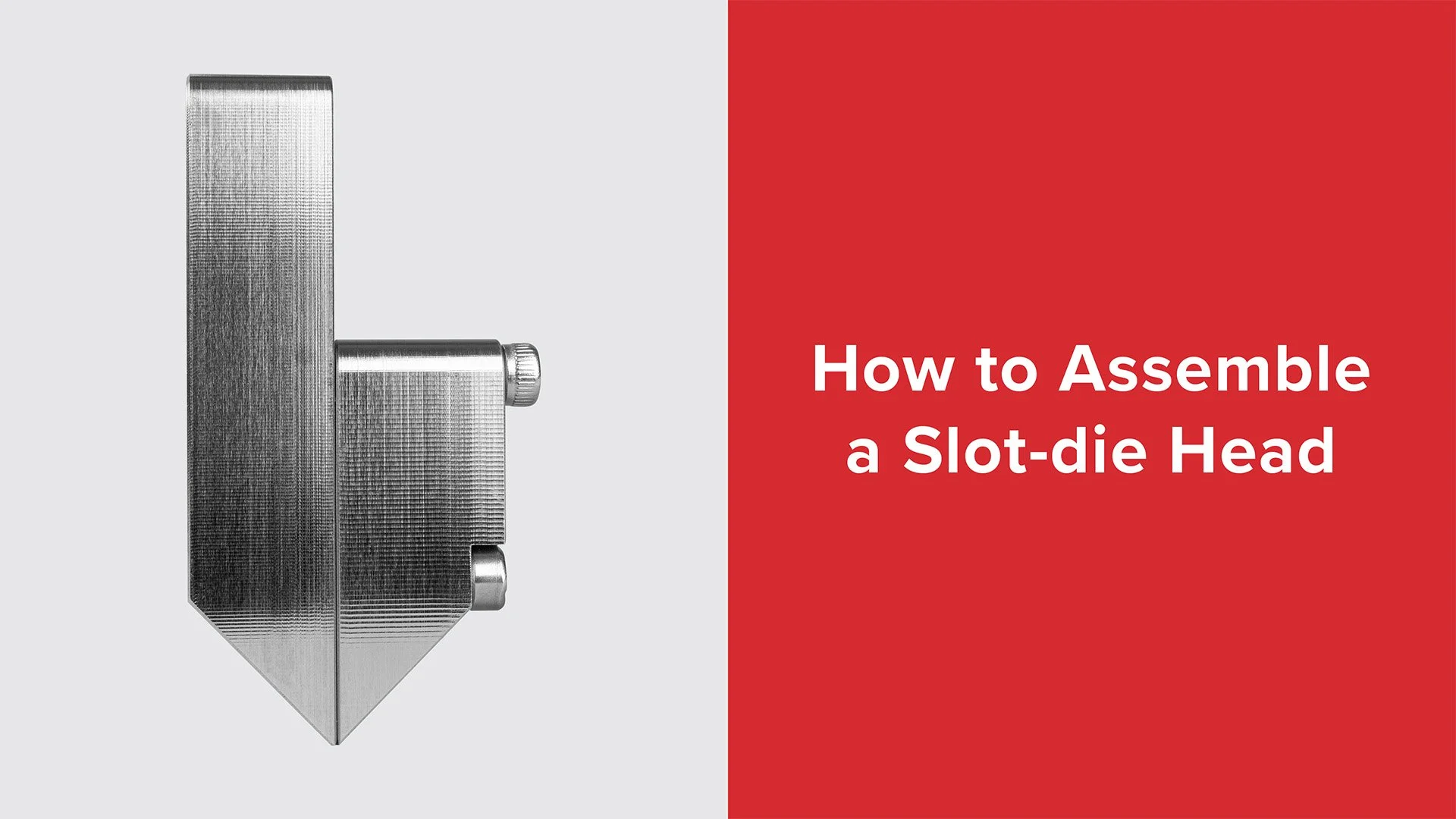

Learn how to assemble a slot-die head step-by-step. View full guide here.

How to Make Solar Cells Using Slot-die Coating

Battery cell fabrication using slot-die coating.

How to Mount a Slot-die Head.

Learn More About Slot-die Coating

FAQs

-

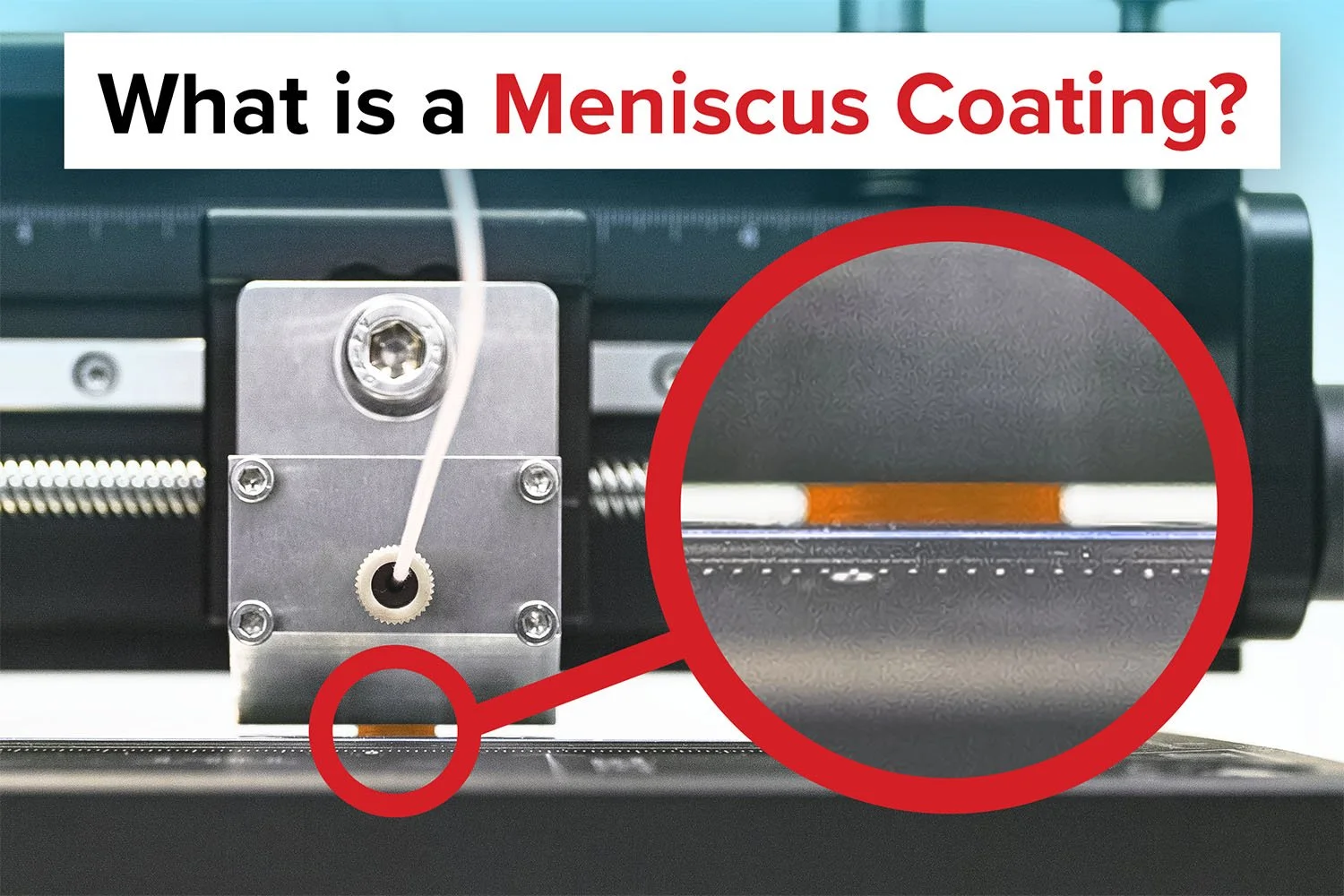

A slot-die head is a precision coating tool used in various manufacturing processes to deposit a uniform layer of material onto a substrate. It operates by forcing a liquid through a narrow slot, which ensures an even distribution across the width of the substrate. Slot-die coating is widely used in industries such as electronics, pharmaceuticals, and renewable energy.

-

Choosing the right slot-die head depends on several factors, including the type of coating material, desired coating thickness, substrate width, and the application. It's important to consider the following:

Coating Material: The viscosity and rheology of your coating fluid will determine the optimal slot gap and lip length.

Coating Thickness: Thicker coatings may require a wider slot opening or higher fluid pressure.

Substrate Width: Ensure that the slot-die head is wide enough to cover the entire width of your substrate.

Application Requirements: Consider if your application requires uniformity, edge control, or multi-layer coatings.

For personalized advice, consult our selection guide or contact our technical support team.

-

We offer slot-die heads in standard sizes of

40 mm Slot-die Head (10/13 mm Working Width)

65 mm Slot-die Head (50 mm Working Width)

115 mm Slot-die Head (100 mm Working Width)

165 mm Slot-die Head (150 mm Working Width)

195 mm Slot-die Head (180 mm Working Width)

305 mm Slot-die Head (280 mm Working Width)

Custom sizes can also be manufactured to meet your specific application needs. The slot gap, which controls coating thickness, can also be customized, usually ranging from 5 microns to several hundred microns.

-

Slot-die heads are commonly made from stainless steel due to its durability, corrosion resistance, and ease of cleaning. However, other materials such as aluminum or specialized alloys can be used depending on the chemical compatibility with the coating material and the operating environment. At infinityPV, we offer slot-die heads in the following materials:

PEEK (Ultra-Lightweight): Ideal for applications where weight is a critical factor.

Stainless Steels (316L Heavy): Known for their durability and resilience.

Titanium (Lightweight): Combining strength with lightweight properties for optimal performance.

-

Lead times vary depending on the complexity and customization of the slot-die head. Standard sizes and materials typically ship within a week, while custom orders may take 6-8 weeks. Expedited manufacturing options are available for urgent needs.

-

Heated Slot-Die Heads: These are designed to maintain or elevate the temperature of the coating fluid, which is essential for materials that require precise temperature control for optimal viscosity and flow properties. Heated heads are ideal for applications involving high-viscosity fluids or temperature-sensitive materials.

Non-Heated Slot-Die Heads: Suitable for materials that do not require temperature control, these are generally simpler and less expensive. They are commonly used for coatings where room temperature is sufficient to achieve desired results.

For an in-depth understanding of the differences between heated and non-heated slot-die heads, check out our comprehensive guide.

-

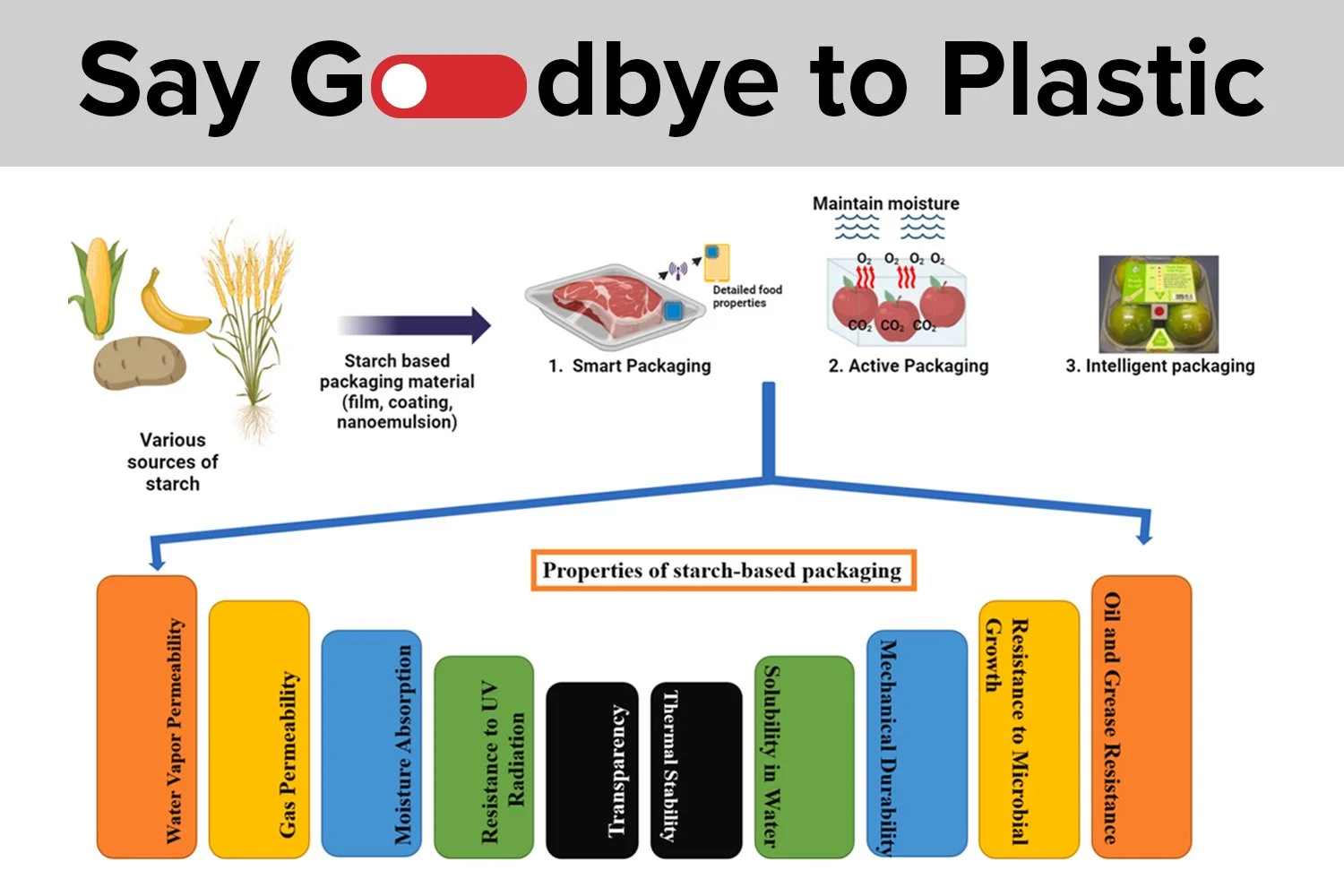

Slot-die heads are versatile and used in a wide range of applications, including:

Electronics: Coating of OLED displays, touchscreens, and printed circuit boards.

Renewable Energy: Deposition of thin films in solar cells, fuel cells, and batteries.

Pharmaceuticals: Coating of tablets, patches, and films.

Packaging: Barrier coatings on paper, plastics, and films.

Automotive: Application of adhesives, sealants, and coatings on automotive parts.

-

Shim kits are used to fine-tune the coating thickness by adjusting the gap between the slot-die lips. They are thin, precision-engineered spacers inserted into the slot-die head to modify the slot opening. Shim kits are essential for applications requiring high precision and consistency in coating thickness.

-

Fitting kits include all necessary hardware and adapters to integrate the slot-die head with your existing coating system. They ensure a secure and precise fit, minimizing the risk of leaks or misalignment. Fitting kits are tailored to your specific equipment and application requirements.

-

Proper maintenance and cleaning are crucial to extending the lifespan of your slot-die head. Regular cleaning prevents the buildup of dried coating materials that could obstruct the slot or damage the head. Use appropriate cleaning solvents compatible with your coating materials, and disassemble the head carefully to avoid damaging any components.

-

Yes, custom slot-die heads can be designed to meet your specific requirements. Customizations can include size, slot gap, material, and additional features such as heating elements or specialized coatings. Contact our engineering team to discuss your unique needs.

-

Precision: Slot-die coating offers unmatched control over coating thickness and uniformity.

Efficiency: It allows for high-speed coating with minimal material waste.

Versatility: Can be used with a wide range of materials and substrates.

Scalability: Easy to scale from lab-scale prototypes to full-scale production.

-

Installation varies depending on your equipment and application. Generally, it involves securing the slot-die head in the coating system, e.g. a Laboratory Roll-to-Roll Coater or a Research Laboratory Coater, connecting the fitting kit, and adjusting the alignment and slot gap. Detailed installation instructions are provided with each slot-die head, and our support team is available to assist with setup.

-

Yes, slot-die heads can be used for multi-layer coatings by stacking multiple heads or using specialized heads designed for simultaneous multi-layer deposition. This is especially useful in advanced electronics and energy applications where different materials need to be layered precisely.

-

Common issues include streaking, uneven coating, and clogging. Solutions often involve adjusting the slot gap, cleaning the head, or modifying the fluid properties. Our troubleshooting guide provides detailed steps for diagnosing and resolving these issues.

-

You can purchase slot-die heads, fitting kits, shim kits, and other accessories directly from our online store or through our authorized distributors. For bulk orders or custom requests, please contact our sales team for a quote.

-

To achieve optimal results, consider adjusting the slot gap, fluid viscosity, and coating speed. For challenging materials, such as high-viscosity or temperature-sensitive fluids, a heated slot-die head may be required.

Consult our technical support for recommendations tailored to your material.

-

Ensure all operators are trained on the equipment and aware of potential hazards, such as high temperatures in heated slot-die heads. Always follow proper cleaning and maintenance protocols to avoid injury and equipment damage. Safety guards and protective gear are recommended during operation.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision laboratory roll-to-roll coating machine that transforms the way thin functional films are printed and coated.

Slot-die Coater

A state-of-the-art, compact sheet coater for precise, consistent slot-die coatings, featuring a vacuum chuck, integrated drying, and optimized ink delivery.