Optimizing Meniscus Behavior in Slot-Die Coating Using Temperature Control: New Insights on Temperature-Controlled Slot-Die Coating

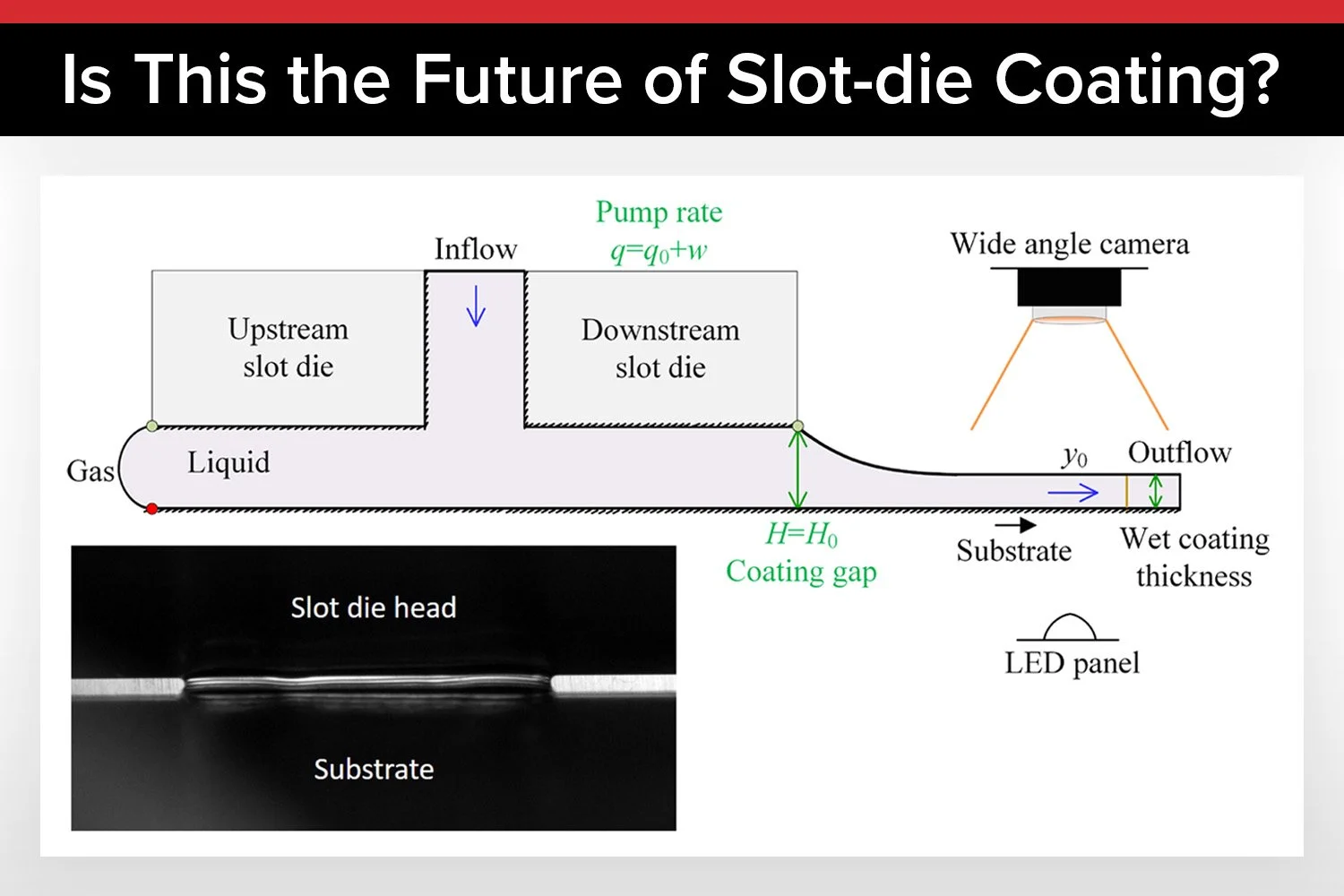

A recent study titled “Evolution Mechanism of Meniscus Formation for Lithium-Ion Battery Electrode Slot Coating with Substrate Heating Module Augmentation” explores how introducing a heated substrate can significantly improve film quality in the slot-die coating process for lithium-ion battery electrodes. By investigating the effects of temperature on meniscus stability and defect formation, the researchers provide valuable insights for engineers and decision-makers working with lab-scale roll-to-roll (R2R) coating equipment.

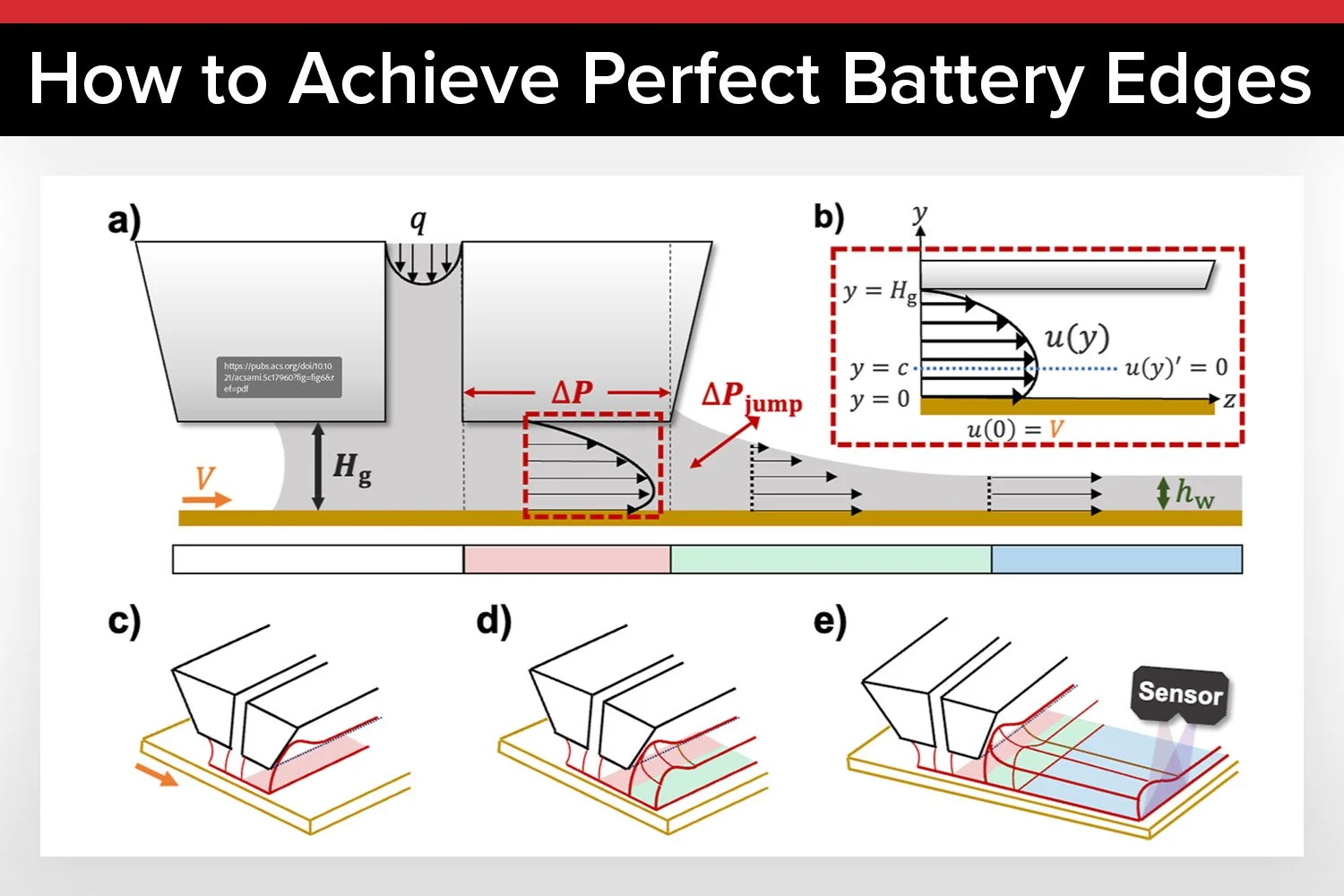

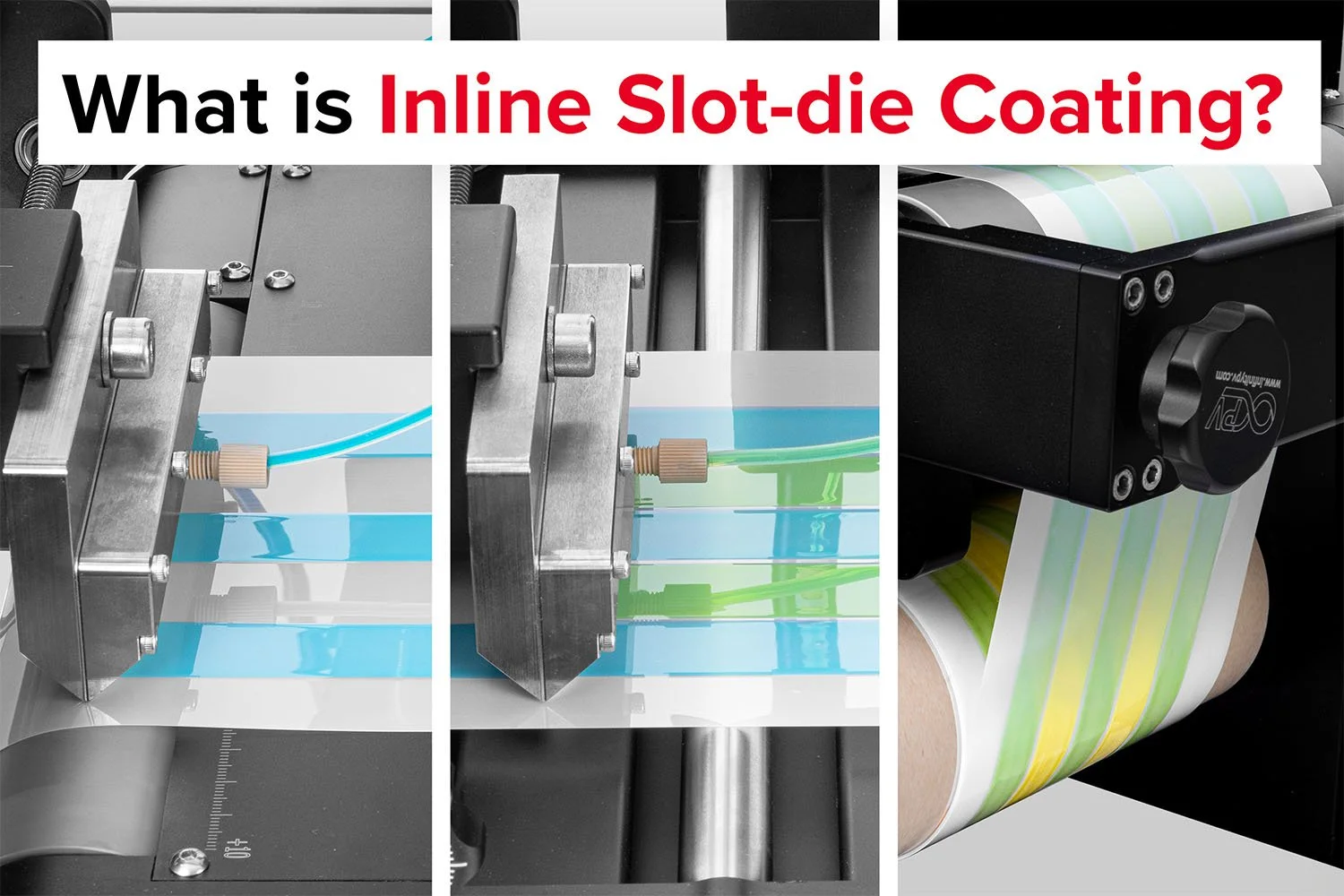

Slot-die coating is favored in battery manufacturing for its precision and scalability. However, defects such as air entrainment and “heavy edges” at the film borders often compromise the quality of electrode layers. This study tackles those challenges by incorporating a substrate heating module to better control slurry viscosity and meniscus dynamics.

The research outlines both theoretical modeling and real-world experiments, offering a roadmap to optimizing slot-die coating parameters and improving defect control. Whether you're setting up a lab-scale coater or refining your existing process, these findings are well worth your attention.

Key Highlights

A heated substrate expands the slot-die coating window and improves process stability

Meniscus behavior is heavily influenced by slurry viscosity, which decreases at higher temperatures

Film defects evolve through three distinct stages: break-line flow, bubble flow, and transition flow

Substrate temperature alters dynamic contact angle and reduces edge bulging

Narrower coating gaps paired with heating reduce edge height due to increased pressure gradients

A validated numerical model simulates the coating bead behavior and meniscus evolution

Experiments show that substrate temperature interacts with coating gap to influence defect patterns

High temperatures improve coating speed limits (Vmax) without sacrificing quality

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

Understanding the Theory: Coating Windows and Meniscus Stability

Slot-die coating is governed by complex interactions between viscous, capillary, and inertial forces. One key concept is the “coating window” – a stable range of process parameters where defect-free films can be produced.

The study uses the capillary number (Ca) and minimum wet film thickness (hm) to define this window. When the capillary number is too low, the upstream meniscus becomes unstable, leading to air entrainment. Conversely, at high Ca, the film may suffer from edge defects due to inertial effects.

By reducing slurry viscosity through heating, the researchers found that the upstream meniscus could be kept stable over a wider range of conditions, thus expanding the coating window.

Methodology: Simulations Meet Experimental Validation

The research team employed a dual strategy: computational fluid dynamics (CFD) modeling using the volume of fluid (VOF) method and physical experiments with slot-die coating equipment.

They modeled the flow and temperature distribution in the coating bead using the Navier-Stokes equations and validated their simulations through lab-scale experiments. Slurries were prepared using graphite and common binders, then coated onto copper foil using controlled temperature and flow settings.

Through systematic variation of coating speed, flow rate, substrate temperature, and coating gap, the study mapped out a highly detailed view of how these variables affect defect formation.

The Slot-die Coater is an excellent choice for researchers focused on developing and optimizing battery electrode slurries at the laboratory scale.

Significance: From Lab to Production

For engineers building lab-scale R2R systems, this study offers practical takeaways. Substrate heating is a relatively easy-to-implement modification that can dramatically improve coating uniformity and reduce costly trial-and-error adjustments.

Heated substrates not only reduce dynamic contact angle but also mitigate “heavy edge” defects that compromise downstream processes like calendering. Since slurry viscosity and flow rate are temperature-sensitive, thermal control becomes an essential design factor for achieving repeatable results.

Importantly, the study also identifies trade-offs. For example, very narrow coating gaps increase pressure drop and reduce edge bulging, but at high temperatures, this can inadvertently increase edge volume flow and worsen bulging. Finding the right balance is critical.

Results: Three Stages of Defect Evolution

One of the most interesting contributions of the study is the identification of three evolutionary stages in coating defects under thermal influence:

Break-line Flow

At lower temperatures, rapid substrate movement stretches the meniscus until it breaks, leaving gaps in the film.Bubble Flow

Slightly elevated temperatures create smaller air pockets, resulting in spotted defects as the air escapes.Transition Flow

At even higher temperatures, the meniscus stabilizes into a sawtooth shape that resists rupture but remains unstable, eventually leading to smooth flow or intermittent defects.

This insight can help researchers better predict and mitigate coating flaws during scale-up or optimization.

Double-sided battery coating on a Laboratory Roll-to-Roll Coater.

Practical Insights for Setting Up Lab-Scale R2R Systems

If you are planning a lab-scale roll-to-roll setup, consider the following implementation strategies drawn from the study:

Use a heated backing roller or substrate stage to reduce slurry viscosity without modifying slurry composition

Design your coating gap to balance pressure gradients and edge flow—narrower gaps are better for minimizing edge defects but require precise temperature control

Monitor upstream meniscus behavior using high-speed imaging or modeling to predict defect zones

Consider that the coating window shifts depending on temperature and flow rate—plan for dynamic parameter adjustments during experimental runs

Conclusion

This study demonstrates that a relatively simple upgrade—a substrate heating module—can have a powerful impact on slot-die coating outcomes. By regulating slurry viscosity and stabilizing the upstream meniscus, engineers can expand their coating window and reduce defects like heavy edges and air entrainment.

For anyone working in lithium-ion battery research or roll-to-roll coating development, especially in lab-scale environments, these findings offer actionable guidance grounded in both theory and experimentation.

Authors

Xiaosong Gong

Dongze Wang

Jiaye Yao

Fei Yan

Xiaozhong Du

Peng Li

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.